JSC SDL Engineering

Contacts

Aleksas Nekrosius

Marketing and Sales

Phone:

E-Mail:

Competencies

Parts (24)

Technologies

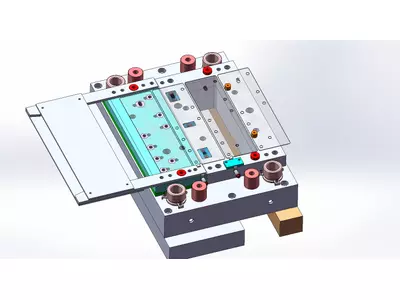

Cutting dies / deep drawing dies

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / Cutting tools | - | 100 - 2400 | 100 - 1000 | 100 - 1000 | - | max. 6000 | - |

Follow-on composite tools | - | 100 - 2400 | 100 - 1000 | 100 - 1000 | - | max. 6000 | - |

Deep-drawing dies | - | 100 - 2400 | 100 - 1000 | 100 - 1000 | - | max. 6000 | - |

Trimming | - | 100 - 1000 | 100 - 1000 | 100 - 1000 | - | max. 6000 | - |

Die replacement / wearing part manufacturing | - | - | - | - | - | - | - |

Embossing / swage dies | - | 100 - 1000 | 100 - 1000 | 100 - 1000 | - | max. 6000 | - |

Company description

SDL Engineering is a young company with high demands on itself and its products. Our core competencies lie in progressive tools, manual tools, gauges and prototypes. As a supplier for the automotive industry, we are familiar with high requirements of this industry and have appropriate quality level designed to. Our customers appreciate us for the following reasons: - The feasibility is always fully verified and confirmed. - The tool costs are exactly calculated and broken. - The methods are always created in the initial phase and provided. - The delivery time for first off-tool parts is 10-12 weeks. The tool takes about 12-14 weeks. - In the first tool fitting for the customer, the project manager is always present. - All construction documents are always acc. ISO / VDA created and placed in project completion are available. - By low wages in Lithuania and wide network of suppliers, we are a good alternative for suppliers from Eastern European countries or Asia. Let yourself be inspired by our expertise and price - take a contact.

Materials

Light metals

Aluminium and aluminium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Tool steel

Spring steel

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.