Karl Rieker KG<br>Spezialbeschläge - Metallverarbeitung

Contacts

Markus Wehle

Commercial management

Phone:

E-Mail:

Competencies

Parts (11)

Technologies

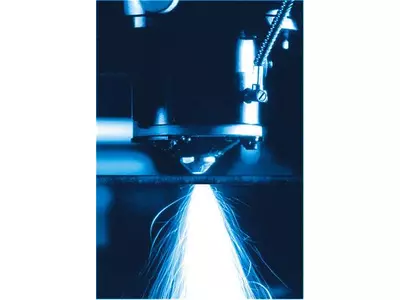

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 100000 | 5 - 900 | 5 - 900 | - | - | max. 50 | 0.5 - 5 |

Company description

The company Karl Rieker KG was founded in 1936 as a hardware store. Over the years and decades, our focus shifted to the Manufacture of fabricated metal products, in particular the Beschlägebau for furniture and kitchen furniture. Our products in the furniture fittings based on own developments or to customer requests for drawing. Due to the existing machinery we are also capable of other Industries to operate. Punching from coil, lasers, welding on robots, assembly work of assemblies and final inspection, machining of metals. Constructions of new products on 3D CAD systems and a separate tool construction for stamping progressive dies, jigs and fixtures is available. Surface treatment: electroplating, galvanizing, powder coating, painting with long-term partner companies

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Laser cutting 2D

Automatic turning (bar)

Bending / folding

Milling

Sawing

Foaming

Rotational moulding

Extrusion blow moulding

Compression moulding

Transfer moulding

Extrusion (profile)

Injection-mould around inserts

Multi component injection moulding

Injection moulding

Roll forming

Full-range turning (including milling)

Inert gas shielded arc welding (MIG/MAG)

Flange bending, profile bending

Form milling (3 D)

Swiss turning

4

3

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Machines (3)

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Tool steel

Spring steel

Industries

Automation and control engineering

Construction and architectural supplies

Building, agricultural and forestry machinery manufacturing

Household appliance industry

Measurement and control technique, laboratory equipment

Precision engineering, mechatronics and optics

Mechanical engineering

Medical technology

Electrical industry

Lighting industry

Automotive and vehicle construction

Machine tool manufacturing

Office machinery and supplies

Furniture industry

Boiler, container and tank construction

Apparatus engineering

Railway and rail vehicles industry

Power generation and transmission industry

Telecommunication industry

Special purpose machinery manufacturing

Information technology (hardware)

Plant engineering and construction

Packaging industry

Aerospace and aviation industry

Air conditioning, refrigeration and ventilation industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.