Leuze GmbH & Co. KG

Contacts

Stefan Leuze

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (6)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 100 - 1000 | max. 1000 | - | - | max. 200 | - | - |

Automatic turning (bar) | 500 - 10000 | max. 50 | - | - | 10 - 50 | - | - |

Full-range turning (including milling) | 100 - 1000 | max. 1000 | - | - | max. 200 | - | - |

Hard turning | 5 - 100 | 20 - 120 | - | - | 20 - 200 | - | - |

Company description

We are a young, dynamic company that is active in the areas of 3 and 5-axis milling, main and counter spindle turning and spark erosive wire cutting. We are also happy to carry out all finishing work for you, such as sanding, hardening or surface treatments. Precision and delivery reliability are our top priorities. Whether it's the smallest tolerances in the area of toolmaking or the fastest delivery dates in the area of prototypes, it's our daily business. We would like to convince you of our services using machines from Hermle, MorisEiki and Charmilles.

Machines (4)

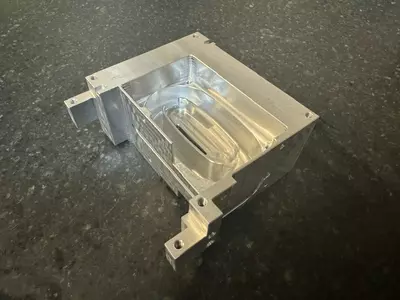

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Cast metals

Cast steel

Cast iron

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Industries

Electrical industry

Drive and gear engineering

Fittings engineering

Medical technology

Mechanical engineering

Plant engineering and construction

Machine tool manufacturing

Power generation and transmission industry

Apparatus engineering

Chemical industry

Building, agricultural and forestry machinery manufacturing

Information technology (hardware)

Automation and control engineering

Automotive and vehicle construction

Precision engineering, mechatronics and optics

Lighting industry

Construction and architectural supplies

Military engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.