LKS-Technik GmbH & Co. KG

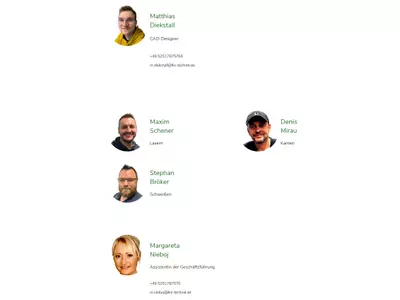

Contacts

Viktor Ruck

Production

Phone:

E-Mail:

Competencies

Parts (1)

Technologies

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 99999998 | max. 99999998 | max. 99999998 | - | - | - | max. 99999998 |

Laser cutting 3D | 1 - 10000 | 1 - 1000 | 1 - 1000 | 1 - 1000 | - | max. 200 | 1 - 15 |

Bending / folding | 1 - 99999998 | max. 99999998 | - | - | - | - | max. 99999998 |

Punching / nibbling | 1 - 99999998 | max. 99999998 | max. 99999998 | - | - | - | max. 99999998 |

Combined forming laser cutting / punching | 1 - 99999998 | max. 99999998 | max. 99999998 | - | - | - | max. 99999998 |

Laser cutting, tube & section | 1 - 99999998 | max. 99999998 | max. 99999998 | max. 99999998 | - | - | max. 99999998 |

Oxyacetylene cutting | 1 - 1000 | 1 - 100 | 1 - 100 | - | - | max. 100 | 1 - 100 |

Plasma fusion cutting | 10 - 1000 | 1 - 100 | 1 - 100 | - | - | max. 100 | 1 - 100 |

Plate rolling / bending | 1 - 99999998 | - | max. 99999998 | - | - | - | max. 99999998 |

Plate straightening | 1 - 11000 | - | 1 - 10 | - | - | - | 1 - 10 |

Shearing (rectangular blank/strip) | 1 - 10000 | - | - | - | - | - | 1 - 3000 |

Company description

Welcome to our young and dynamic company in Paderborn! We started 2019 with a case of beer and an idea and have now developed into a successful company with 14 dedicated employees. We owe this in particular to our fast and efficient single-part and small series production in the areas of laser cutting, edging and welding. Our passion for precision and quality has made us a reliable partner for many companies in the region. We offer you tailor-made solutions that are perfectly tailored to your individual requirements. In doing so, we rely on the latest technologies and the high level of expertise of our employees in order to offer you the best possible quality and efficiency. We see ourselves as your reliable partner and do everything we can to exceed your expectations. Our close cooperation and transparent communication guarantee a smooth execution of your projects. In doing so, we always remain flexible and adapt to your needs. Let yourself be convinced of our performance and commitment. We look forward to meeting you and working with you to successfully implement your projects. Contact us today!

Machines (3)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Industries

Mechanical engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.