MD Composites Technology

Contacts

Competencies

Parts (7)

Technologies

Water jet cutting

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Water jet cutting 2D | 1 - 10000 | 1 - 4000 | 1 - 3000 | - | - | - | 0.01 - 300 |

Company description

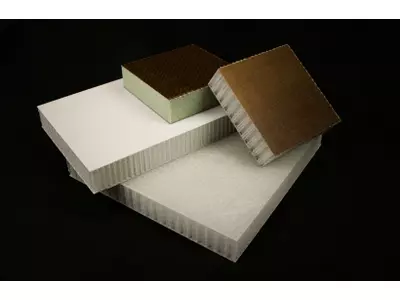

MD Composites Technology is part of the MD Group based in Friedeburg / Lower Saxony. Our core competence is the development and production of lightweight components made of fibre-reinforced plastics (GRP/CFRP) - we make heavy things light and give shape to complex things! What we stand for: We develop, design and produce components for applications in wind power, hydropower, aviation, agricultural and medical technology. Solutions for maritime applications or in the field of renewable energies, electromobility and electrical engineering round off the portfolio. Wherever stable, high-strength, lightweight and corrosion-free materials with customer-defined properties are required, MD Composites is the right partner. Our processes: - Water jet machining 2D / 2.5D - Vacuum infusion - Resin injection moulding (RTM) - Hand layup - Reaction Injection Moulding (RIM) - Foaming - Mould production / model production

Machines (1)

Copmany images

Materials

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Non-metal inorganic materials

Ceramics

Cast minerals

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Natural materials

Wood/timber

Rock

Industries

Air conditioning, refrigeration and ventilation industry

Building, agricultural and forestry machinery manufacturing

Aerospace and aviation industry

Chemical industry

Railway and rail vehicles industry

Plant engineering and construction

Medical technology

Mechanical engineering

Boiler, container and tank construction

Power generation and transmission industry

Automotive and vehicle construction

Military engineering

Shipbuilding industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.