MECAFLEX sa

Contacts

thomas janquart

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

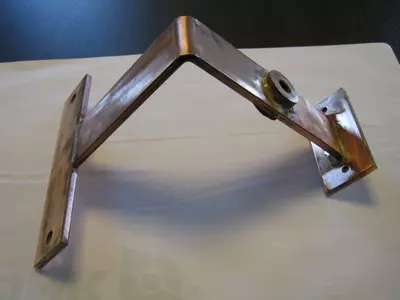

Parts (6)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 20000 | 1 - 700 | - | - | 50 - 400 | - | - |

Full-range turning (including milling) | 1 - 20000 | 1 - 700 | - | - | 50 - 400 | - | - |

Company description

We are one machining and turning shop specialized in batch production. We offer high reactivity to customer's demand and competitives prices. Business area: We are focused on production of parts requesting very competitives prices with high quality standard and high delivery performance on the long-term. We try to focus on long-term partneship by offer the best servies level, prices and quality to our customers. We try to share as much as possible to create a win-win situation for us and our customers. Batches/quantities: We used to deal with annual demand from 0 to 20.000 units. Our best prices will be for production batches ranging from 0 to 1000 units. Materials: Today, we mainly deal with different steel grades and aluminum. Technical capabilities: - vertical and horizontal CNC machining centers - machinig of parts with maximum size 1200 X 600 X 500mm. - turning of parts of macimum 350mm diameter and 1000mm length Machines list: Vertical machining center -> mazak vtc 20 - 1500X500X500 mm Vertical machining center -> leadwell 50I - 1200X600X600 mm Vertical machining center -> leadwell 20I - 500X350X300 mm Vertical machining center -> cincinati arrow - 750X500X500 mm Horizontal machining center -> mazak H400 - APC - 400X400 mm Horizontal machining center -> OKUMA MH40-A - APC - 400X400 mm CNC turning machine -> Dainichi dia 200X600 mm CNC turning machine -> mazak dia 250X1000 mm CNC turning machine -> leadwell dia 350X600 mm CNC turning machine -> leadwell dia 150X600 mm with automatic feeding 2 threading machines M3 - M24 Band saw -> everising dia 350 mm CNC Band saw -> mep shark dia 250 mm Mesuring equipement -> 2x Tesa 2D microhite

Machines (11)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Cast metals

Cast steel

Cast iron

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Plastics/synthetic materials

Thermoplastics

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Industries

Paper and printing machinery industry

Fittings engineering

Hydraulic and pneumatic industry

Building, agricultural and forestry machinery manufacturing

Mining and tunnel engineering

Boiler, container and tank construction

Special purpose machinery manufacturing

Shipbuilding industry

Construction and architectural supplies

Lighting industry

Automation and control engineering

Railway and rail vehicles industry

Packaging industry

Automotive and vehicle construction

Air conditioning, refrigeration and ventilation industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.