Metallbau Liesner

Contacts

Andreas Liesner

Owner, company manager, member of the board

Phone:

E-Mail:

Andreas Liesner

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (4)

Technologies

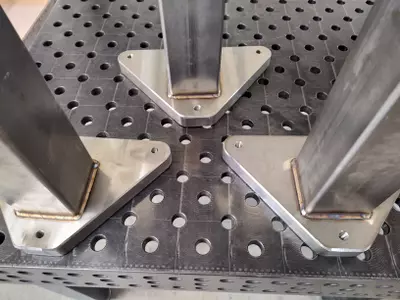

Welded constructions / Structural Steelwork

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Welded constructions (weldments) | - | max. 10000 | max. 10000 | max. 10000 | - | max. 3000 | - |

Machine frames / bases / racks | - | 1 - 10000 | 1 - 10000 | 1 - 10000 | - | 0.1 - 3000 | - |

Company description

Dear Sir or Madam, you are certainly familiar with the problems when working with other suppliers regarding a lack of quality, delivery reliability or flexibility for rush orders or repairs and spare parts production. We, at Metallbau Liesner, understand this problem and take your demands extremely seriously. Through targeted collaboration with specialized companies for material procurement, we have specialized in developing tailor-made solutions, completing projects quickly and reliably adhering to agreed delivery dates. If you would like to find out more about the company and the values we live by every day, visit our website at www.metallbau-liesner.de or contact us directly at info@metallbau-liesner.de. We are also happy to help you by phone on 0049 2865 6035740 or mobile at 0049 17631355996.

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Light metals

Aluminium and aluminium alloys

Industries

Building, agricultural and forestry machinery manufacturing

Machine tool manufacturing

Special purpose machinery manufacturing

Boiler, container and tank construction

Plant engineering and construction

Mechanical engineering

Apparatus engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.