MICROTECNICA TREVISANA S.n.c. di Bruna Maria Spricigo & Figli

Contacts

Luca Gusso

Production

Phone:

E-Mail:

Competencies

Parts (4)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 5000 - 10000000 | 1 - 150 | - | - | 5 - 60 | - | - |

Automatic turning (bar) | 5000 - 10000000 | 1 - 150 | - | - | 5 - 60 | - | - |

Swiss turning | 5000 - 10000000 | 1 - 150 | - | - | 5 - 60 | - | - |

Full-range turning (including milling) | 5000 - 10000000 | 1 - 150 | - | - | 5 - 60 | - | - |

Broaching | 5000 - 10000000 | 1 - 150 | - | - | 5 - 60 | - | - |

Deep-hole drilling | 5000 - 10000000 | 1 - 150 | 1 - 150 | 1 - 150 | 5 - 60 | max. 0.3 | - |

Centering / end facing | 5000 - 10000000 | 1 - 150 | - | - | 5 - 60 | - | - |

Shaft machining | 5000 - 10000000 | 1 - 150 | - | - | 5 - 60 | max. 0.3 | - |

Company description

Microtecnica Trevisana is a leading manufacturer of precision turned small metal parts, accessories for radiators, precision turned parts, ball bearings and mechanical components. Microtecnica Trevisana is an automatic turning for the production of turned parts. We have sevral multi-spindle lathes machining brass and automatic steels. Our capacities consists of 45 multi-spindle lathes (8 spindles) with pick-up, stop-spindle devices and CNC slides. Our capacity list includes: - TAJMAC MULTI-SPINDEL (MORI-SAY 8/32, 8/42, 6/20, 6/25, 6/42) - TAJMAC MULTI-SPINDEL CNC (TMZ 8/67, 6/42) - SCHÜTTE MULTI-SPINDEL (AG-20) Since 2006 we have been installing 6 TRANSFER machines (BUFFOLI E GNUTTI) to increase our capacity and meet with the more and more complex customers' requirements. Moreover, in order give a full service to our customers, our production includes: - 2 IFP washing machines (ultrasonic washing with modified alcohols) - Automatic equipment to assemble o-rings and other components - 1 automatic line for the creation of blisters - 1 automatic line for assembling and labelling of boxes - 1 vibrating machine RÖSLER to improve the surface finish of the parts Materials The tipically machined materials are: - BRASS (CW614N, CW617N, CW612N, CW602N, CW625N, CW626N, CW510L, CW511L, Ecobrass, etc.) - Automatic steel (11SMnPb37, 11SMnPb30, 11SMn37, 11SMn30, 36SMnPb14, etc.) Tools and instruments: While producting, the following instruments are used: - 2 sorting machines DELTA VISIONE; - 2 optical measuring machines KEYENCE; - CENT gauges with digital output data; - MICROMETERS (0-25 and 25-50) with digital output data; - TOOLS FOR MEASURING holes and threads (GO-NOT GO GAUGES); - COMPORATIVE digital gauges for special measurements; - DIGITAL and ANALOGIC TOOLS for the measurement of gorges; - INSTRUMENT FOR ROUGHNESS MEASUREMENTS; - SMARTSCOPE FLASH OGP (optical machine).

Machines (4)

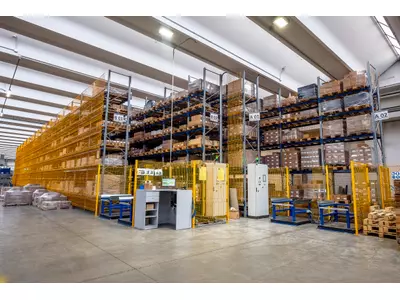

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Solder

Steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Industries

Mechanical engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.