Mitec srl

Contacts

Pagliarani Imerio

Production

Phone:

E-Mail:

Competencies

Parts (8)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 100000 | 2 - 560 | - | - | 10 - 70 | - | - |

Automatic turning (bar) | 1 - 100000 | 2 - 560 | - | - | 10 - 70 | - | - |

Full-range turning (including milling) | 1 - 100000 | 2 - 560 | - | - | 10 - 70 | - | - |

Hard turning | 1 - 100000 | 2 - 560 | - | - | 10 - 70 | - | - |

Broaching | 1 - 100000 | 2 - 35 | - | - | 10 - 70 | - | - |

Company description

MITEC S.R.L was born in 2009 from the evolution and decades of experience in the mechanical sector of the owner who after 30 years at the service of the family company chooses the technological renewal investing all of himself on his new adventure. In a few years new numerically controlled lathes, vertical machining centers and injection molding machines for the molding of plastic materials are purchased; MITEC SRL is at the service of the largest companies in the surrounding area, gaining more and more trust and consensus thanks to its versatility that allows you to realize pre-assembled components and kits for different sectors: industrial doors, gates, sliding systems, packaging, automatic machines, industrial kitchens and medical. MITEC S.R.L extends over a total area of 2,800 square meters of which 1,250 square meters of production area (2/3 production and 1/3 warehouse and offices) and the remaining loading / unloading area and courtyard. Currently there are 12 employees plus 1 worker and 1 administrative assistant for a total of 14 employees.

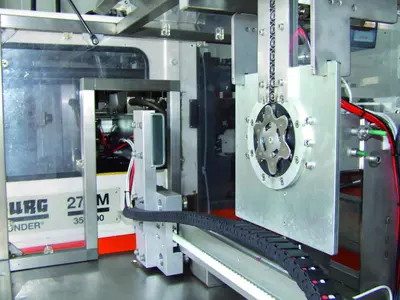

Machines (12)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Cast metals

Cast steel

Cast iron

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.