Osterrath GmbH & Co. KG

Contacts

Patrick Sassmann

Marketing and Sales

Phone:

E-Mail:

Competencies

Parts (8)

Technologies

Sheet Metal Forming (Stamping, Deep-drawing)

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / pressing (Out-of-tool) | 10000 - 99999998 | 2 - 120 | 2 - 80 | - | - | - | 0.1 - 2 |

Stamping and bending machine (Bihler) | 1000 - 9999999 | 0.8 - 80 | 0.1 - 80 | - | - | - | 0.08 - 2 |

Deep-drawing | 1000 - 10000000 | 2 - 20 | 2 - 20 | 2 - 20 | - | - | 0.5 - 1.5 |

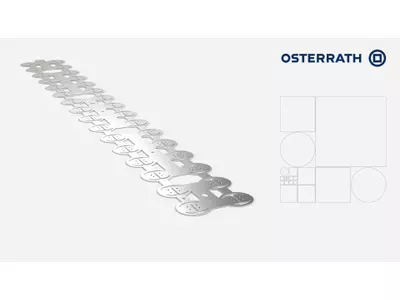

Company description

It´s the small things that make the world move. The precision of our stamped and formed parts is critical tot he qualtity and dependability oft he goods produced by our customers. products: - tubular parts - stamped parts materials: beryllium copper springsteel copper bronce brass steel stainless steel aluminium nickel german silver range of products: sleeves with outside diameter of 0,8mm to 42mm: example: cylindrical sleeves oblonge sleeves profile sleeves Ferrule precision tubular parts with outside diameter of 0,8mm to 42mm: examples: rivets as per DIN 7340, eyelets base pins crimp sleeves collar sleeves tubular precision part as per customized drawing stamped parts with material thickness 0,1 to 2,0mm, in bulk or on reels: examles: contact spring fuse clips solder tag solder pin cable shoe battery clip terminal tabs crimp contact terminal with thread products for electric and electronic industry deep drawn products stamped parts as per customized drawing own toolroom heat treatment and surface treatment / plating in inhouse galvanic: hardening and soft annealing is possible plating examples: nickel tin copper silver gold zinc etc.

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Pipe forming

1

Machines (9)

Copmany images

Materials

Precious metals

Silver

Gold

Light metals

Aluminium and aluminium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Industries

Measurement and control technique, laboratory equipment

Mechanical engineering

Automotive and vehicle construction

Precision engineering, mechatronics and optics

Special purpose machinery manufacturing

Electrical industry

Automation and control engineering

Fittings engineering

Drive and gear engineering

Apparatus engineering

Lighting industry

Furniture industry

Machine tool manufacturing

Household appliance industry

Packaging industry

Medical technology

Hydraulic and pneumatic industry

Power generation and transmission industry

Plant engineering and construction

Telecommunication industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.