PMP Meccanica Srl

Contacts

Competencies

Parts (19)

Technologies

Finishing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

External cylindrical grinding | 1 - 1000 | 1 - 1600 | - | - | 1 - 450 | max. 130 | - |

Internal cylindrical grinding | 1 - 1000 | 1 - 300 | - | - | 1 - 450 | - | - |

Surface grinding machine | 1 - 1000 | 1 - 340 | 1 - 750 | 1 - 280 | - | max. 420 | - |

Coordinate jig grinding | 1 - 1000 | 1 - 300 | 1 - 500 | 1 - 450 | - | max. 250 | - |

Shot blasting | 1 - 1000 | 1 - 620 | 1 - 900 | 1 - 650 | - | max. 100 | - |

Company description

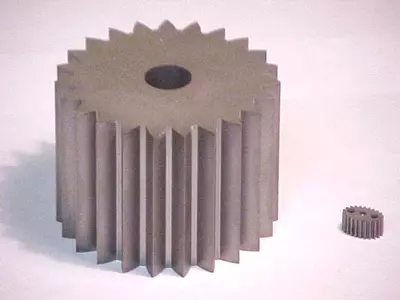

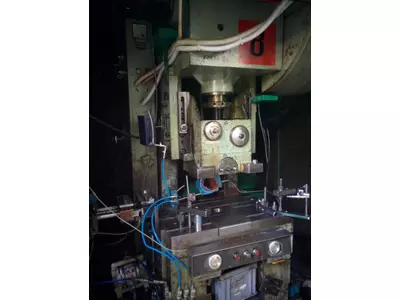

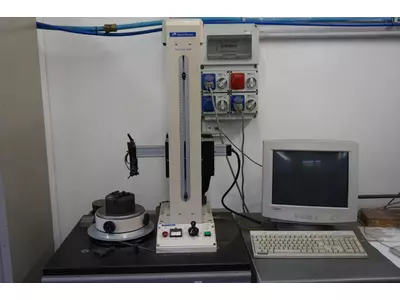

PMP Meccanica is a company headquartered in Lippo di Calderara in the province of Bologna, which was founded in 1961 starting to stamp sheet metal. With years the experience increases and to reduce the time of delivery and external machining PMP Meccanica starts to gear up internally for the production of molds refining the quality. Gradually this part of tooling evolves allowing also the production for other customers expanding its scope to pieces for multiple sectors such as aeronautical, medical, packaging, and sintering powders. Today, thanks to a cutting-edge machinery and capable staff, PMP Mechanics is a leader in the field of precision mechanics and in the normal and semi-fine blanking. Currently PMP Meccanica employs 50 people of which 30 are engaged in the tooling branch and 20 in the blanking. The mantra and backbone of PMP Mechanics has been always the thought of the founder Marziano Pancaldi ie "We can build all that we can measure." It is therefore evident the necessity to have a constant quality control during the whole production process to ensure the quality of the product and the tolerances required by the Customer.

Machines (66)

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Advanced Materials

Carbide

Industries

Precision engineering, mechatronics and optics

Automotive and vehicle construction

Aerospace and aviation industry

Mechanical engineering

Medical technology

Machine tool manufacturing

Packaging industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.