Pro Tools Solutions GmbH

Contacts

Arnold Gasser

Owner, company manager, member of the board

Phone:

E-Mail:

Christine Kranebitter

Others

Phone:

E-Mail:

Competencies

Parts (2)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 100 | 1 - 1000 | - | - | 1 - 500 | - | - |

Automatic turning (bar) | 1 - 1000 | 1 - 600 | - | - | 1 - 500 | - | - |

Company description

The tool management includes: • Check the tool drawings in collaboration with customers • Create schedules in MS Project • Ongoing status reports • On-site monitoring of the toolmaker • monitoring compliance dates • Progress Monitoring • Review getätigter work • Reconciliation schedules with customers and suppliers • root cause analysis of delays and action planning • vote to be carried out tool changes or their fastest possible implementation • Tool will inspect tool acceptance report The ever shorter lead times for the development and production of prototype and production parts, especially in the automobile sector, demand a detailed planning of the individual or parallel projects to save costs and time. We offer complete transparency regarding the project progress, the crucial exercises to project success. To ensure that your project goes according to plan, our team takes on the progress monitoring tool and provides the appropriate status reports.The earlier we are entrusted with the management tool, the easier we can make reference to the flowcharts, bottlenecks and Narrow by concrete measures. Tool changes to be managed in the short term and on time from us. Based on available data of the components, we assume the timely procurement of necessary resources such as tools. In consultation with you product features, function, and any added components will be discussed. Thus, the optimal process engineering can be determined and the most suitable manufacturer can be selected. We will also guide you in its care: scheduling, determining the organizational and technical processes, to process optimization procedures, for the precise implementation. The documentation of all processes and changes in the life cycle is a matter of course. Pending the completion of the project, we are your partner. Tool and die Injection molding tools; small batch tools and prototype tools made of aluminum includingProduction of components; Space Puzzle Molding; RRIM tools, stamping tools, die-casting molds, trimming or deburring tools; production of small series for general engineering (up to 1,000)

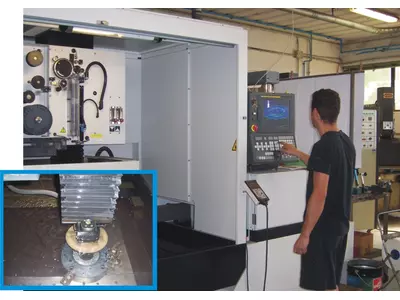

Machines (6)

Copmany images

Materials

Plastics/synthetic materials

Thermoplastics

Elastomers

Glass fibre-reinforced plastic

Light metals

Aluminium and aluminium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Steel

Case hardening/tempering steel

Free-cutting/mild steel

Tool steel

Industries

Construction and architectural supplies

Automotive and vehicle construction

Fittings engineering

Drive and gear engineering

Electrical industry

Measurement and control technique, laboratory equipment

Power generation and transmission industry

Hydraulic and pneumatic industry

Paper and printing machinery industry

Military engineering

Air conditioning, refrigeration and ventilation industry

Household appliance industry

Office machinery and supplies

Automation and control engineering

Chemical industry

Railway and rail vehicles industry

Information technology (hardware)

Boiler, container and tank construction

Aerospace and aviation industry

Medical technology

Special purpose machinery manufacturing

Building, agricultural and forestry machinery manufacturing

Plant engineering and construction

Apparatus engineering

Lighting industry

Clean room technology

Shipbuilding industry

Telecommunication industry

Packaging industry

Machine tool manufacturing

Mining and tunnel engineering

Precision engineering, mechatronics and optics

Mechanical engineering

Furniture industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.