PROTOMASTER GmbH

Contacts

Axel Wolf

Marketing and Sales

Phone:

E-Mail:

Competencies

Technologies

Sheet Metal Forming (Stamping, Deep-drawing)

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / pressing (Out-of-tool) | 1 - 500000 | 100 - 4500 | 100 - 2500 | - | - | - | 0.5 - 5 |

Deep-drawing | 1 - 500000 | 100 - 4500 | 100 - 2500 | 100 - 500 | - | - | 0.5 - 5 |

Company description

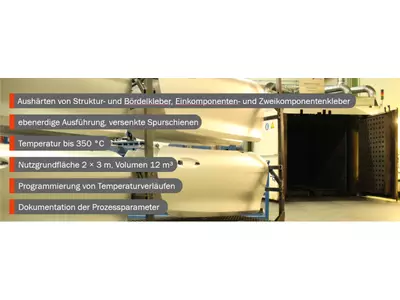

As a long-standing supplier of well-known German OEMs, we are mainly engaged in the production of individual body parts and assemblies through to ready-to-paint hang-on parts. In doing so, we can represent almost all steps of product development in-house: - Method planning and forming simulation - Tool and equipment design and production in-house - Manufacture of individual sheet metal parts and sub-assemblies made of aluminum or steel - manual or robot-assisted production of complex assemblies (e.g. side doors, front flaps, tailgates, spoilers, tank and load hatches, etc.) Our flexible and experienced employees as well as universal manufacturing systems enable us to economically represent both prototypes and small and medium-sized series of large parts (car sidewall, floor groups). Even in the high-volume sector, we support our customers with smaller components (e.g. tank and loading hatches). Of course, we also have sufficient experience and the technical capabilities to implement manual joining technologies, such as resistance point, MAG, MIG, TIG welding, nut and bolt welding, punch riveting, clinching, roll folding, gluing, etc. With our manual transfer large and servo-hydraulic transfer presses including decoiling system and circuit board cleaning, 3D lasers, universal robotic systems, a CNC-controlled shell furnace and also the finishing of outer skin components, we believe that the ideal conditions are available to also take over your component supply. We are also happy to answer your inquiries about production relocations or spare parts production after series production has ended, with downstream KTL coating from long-standing partner companies if required. Components for metal chair furniture (metal seat shells/frames) round off our portfolio even outside automotive production.

Machines (6)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Cast metals

Cast steel

Cast iron

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Advanced Materials

Carbide

Industries

Plant engineering and construction

Mechanical engineering

Automotive and vehicle construction

Building, agricultural and forestry machinery manufacturing

Furniture industry

Military engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.