Rimec Group srl

Contacts

Cinzia Gennarelli

Marketing and Sales

Phone:

E-Mail:

Deborah Dini

Commercial management

Phone:

E-Mail:

Competencies

Parts (16)

Technologies

Finishing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

External cylindrical grinding | 10 - 30000 | 10 - 400 | - | - | 8 - 80 | - | - |

Internal cylindrical grinding | 10 - 30000 | 10 - 100 | - | - | 10 - 150 | - | - |

Centreless grinding | 10 - 100000 | 10 - 500 | - | - | 8 - 50 | max. 20 | - |

Company description

WE INFORM YOU THAT RIMEC GROUP WILL BE CLOSED FOR SUMMER VACATION FROM 09 TILL 22 AUGUST INCLUDED. Rimec Group is a company that manufactures mechanical components for a variety of industrial sectors. We have been investing for years both in technological research processes and in the development of leading-edge solutions for the mechanical products machined in our workshops. We have specialised in the construction of shafts and worm gears for winches and reduction gearboxes, link and pivot pins for lifting systems, adjustable stretchers and anchor fittings for fleyer chains, track rollers and sprockets for construction equipment undercarriages, and Twist locks, which are safety components for the handling of containers. We hold UNI EN ISO 9001-2015 and UNI EN ISO 14001:2015. The Rimec Group corporate structure is able to handle all phases of the order, starting from purchase of the raw material through to delivery of the finished product, which can also be assembled in our contract assembly division to the customer’s specifications. All processing steps, from issue of the order to shipment of the finished product, are handled by a computerised bar-code system. Apart from its in-house machining and other processes, Rimec is able to draw on its know-how and a dense network of partner firms inside and outside the group to deliver special heat and surface treatments, such as Case hardening, Induction hardening, Ferritic nitrocarburising, Galvanisation Painting, Chemical nickel plating, Chromium plating and Phosphating

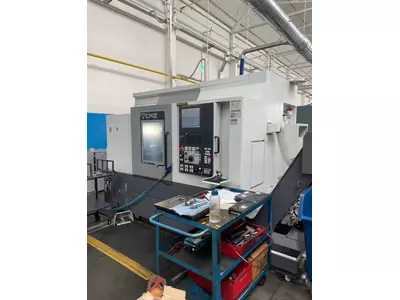

Machines (39)

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Light metals

Aluminium and aluminium alloys

Cast metals

Cast steel

Cast iron

Industries

Mechanical engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.