Steker s.r.o.

Contacts

Pavel Steker

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (10)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 10 - 500000 | 100 - 1000 | - | - | 200 - 99999998 | - | - |

Full-range turning (including milling) | 10 - 500000 | 100 - 1000 | - | - | 200 - 99999998 | - | - |

Company description

Since 2004, our company has been providing cutting-edge services in the field of CNC machining of metals and plastics. Our production hall, which covers an area of 2340 m², is equipped with the latest technologies that ensure efficient fulfillment of all quality requirements for our products. Our professional services are sought after by both domestic and foreign companies from various industries. We invest tens of percent of our annual profits in the modernization of our technologies and in the further training of our employees. We currently employ 45 employees whose expertise and skills enable us to make the most of our technical and mechanical equipment. We are characterized by exceptional workmanship, a personal approach to each customer and a wealth of references from many industries. We specialize in CNC machining, from piece production to high-volume production, and offer part measurement with reporting on a Wenzel 3D gantry measuring machine. We also provide assembly of assemblies and perform surface finishing to customer specifications. Our versatile five-axis machining centers enable efficient complex milling. We utilize palletizing of five-axis and horizontal machines to maximize efficiency and setup speed in repetitive production. Through automation and priority machine control, we guarantee to meet deadlines for serial orders. Our major customers include companies in the optical and medical device industry, high-speed doors, agricultural equipment and automotive industry. Our company has implemented a quality management system in accordance with ČSN EN ISO 9001:2016, which guarantees the high quality of our products. We are currently in the process of implementing the IATF 16949:2016 standard, which we expect to complete in mid-2025.

Machines (10)

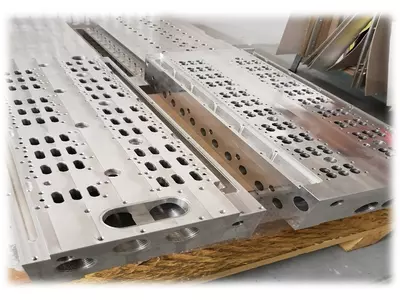

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Cold extruding steel

Plastics/synthetic materials

Thermoplastics

High performance plastic

Thermosets

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Cast metals

Cast steel

Cast iron

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Industries

Railway and rail vehicles industry

Drive and gear engineering

Automotive and vehicle construction

Building, agricultural and forestry machinery manufacturing

Mechanical engineering

Air conditioning, refrigeration and ventilation industry

Paper and printing machinery industry

Precision engineering, mechatronics and optics

Hydraulic and pneumatic industry

Machine tool manufacturing

Chemical industry

Medical technology

Military engineering

Furniture industry

Packaging industry

Automation and control engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.