STS Systemtechnik Schänis GmbH

Contacts

Marlis Göldi

Marketing and Sales

Phone:

E-Mail:

Marcel Oberholzer

Phone:

E-Mail:

Armin Gallati

Marketing and Sales

Phone:

E-Mail:

Competencies

Parts (8)

Technologies

Sheet Metal Forming (Stamping, Deep-drawing)

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / pressing (Out-of-tool) | 8000 - 10000000 | 5 - 2500 | 5 - 500 | - | - | - | max. 3 |

Stamping and bending machine (Bihler) | 8000 - 10000000 | 5 - 2500 | 5 - 500 | - | - | - | 0.1 - 10 |

Deep-drawing | 1000 - 10000000 | max. 2500 | max. 500 | max. 500 | - | - | max. 10 |

Company description

We process metal with heart and mind The proof of market relatedness and continuity Since its founding in 1924, we maintain a thriving collaboration with numerous commercial and industrial companies. The foundation for mutual success is our long-standing experience and expertise, our unrivaled performance and our legendary reliability. Our market and services We solve the specific tasks with all our knowledge and the latest tooling technology. We support our customers with passion through all phases of a project, however complex and convincing a perfect solution, as well as cost and schedule adherence. As a supplier in the field of punching, bending, pressing, we are equipped with latest machines and measurement techniques. Our strengths lie mainly in the tool Falling production for sheet thicknesses from 0.4 to 4.0 mm. In addition to manufacturing these parts further post-processing are possible in our home; trovalizing / vibratory grinding, cleaning, powder coating, painting. Our core competencies in sheet metal processing (stamping, bending, welding, assembly, etc.) are the result of many years of experience. Specific duties of our customers require individual solutions. We support our customers knowledgeable about all phases of a project, ie from consulting to product delivery. Here convince our services both professionally and cost comparatively as well as scheduled. Contributing a modern tooling and powerful resources at critical. Our competencies Development and Planning Toolmaking Punching Assembly Welding Powder coating

Machines (10)

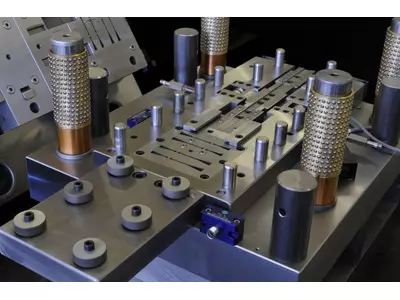

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Industries

Hydraulic and pneumatic industry

Drive and gear engineering

Household appliance industry

Lighting industry

Mechanical engineering

Telecommunication industry

Measurement and control technique, laboratory equipment

Automotive and vehicle construction

Construction and architectural supplies

Medical technology

Air conditioning, refrigeration and ventilation industry

Electrical industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.