Tyrpanis I.Sons GP

Contacts

Nikos Tyrpanis

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (15)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 100000 | 1 - 8000 | - | - | 1 - 1250 | - | - |

Automatic turning (bar) | 1 - 100000 | 1 - 1255 | - | - | 1 - 366 | - | - |

Swiss turning | 1 - 1000000 | 1 - 500 | - | - | 1 - 366 | - | - |

Full-range turning (including milling) | 1 - 100000 | 1 - 1255 | - | - | 1 - 366 | - | - |

Hard turning | 1 - 100000 | 1 - 1255 | - | - | 1 - 366 | - | - |

Broaching | 1 - 10000 | 1 - 300 | - | - | 1 - 600 | - | - |

Deep-hole drilling | 1 - 10000 | 1 - 3600 | 1 - 1100 | 1 - 900 | 1 - 1600 | max. 5000 | - |

Centering / end facing | 1 - 100000 | 1 - 8000 | - | - | 1 - 1600 | - | - |

Shaft machining | 1 - 100000 | 1 - 8000 | - | - | 1 - 1250 | max. 10000 | - |

Company description

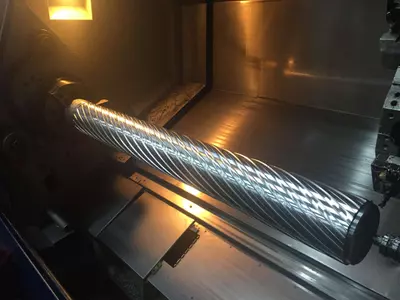

We undertake the manufacture of complete assemblies and machines, according to the needs of your company, targeting to the maximum efficiency for your production. We utilize new technologies and production techniques to benefit our clients; the constant renewal of our equipment and renovation of our facilities prove our commitment to this goal. We also run a commercial section, offering a wide range of industrial components, spare parts, tools and raw materials. Tyrpanis Company was founded in 1968 by Ioannis Tyrpanis. Νowadays, it is being administrated by his sons and is situated in Lefki Xanthis, Greece, in proprietary facilities of over 3,000 sq.m. After 50 years of experience in the machine shop industry, it is considered as one of the top greek machine shops and retains partnerships with major technical companies and research institutes. We strive for the constant modernization of our equipment and internal procedures, aiming for the best outcome with our products and services. We perform various types of analyses in ferrous metals by use of SPECTRO laboratorial spectrometer, identifying the material of the provided sample. Our CNC machining operates in 3, 4 and 5 axis, using lathes and vertical machining centers by DMG MORI and Doosan Infracore. We are able of performing lathing and grinding works in shafts of length up to 8,000mm and diameter up to 1,250mm. We utilize a full instrument set of SKF for full alignment of pulleys and shafts, induction heater for easy and correct bearing placement, stroboscope, as well as a portable balancing device. We perform operations of steel carbonization and hardening, using specialized immersion furnaces by Durferrit.

Machines (1)

Copmany images

Materials

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Industries

Military engineering

Shipbuilding industry

Power generation and transmission industry

Mining and tunnel engineering

Plant engineering and construction

Chemical industry

Medical technology

Packaging industry

Machine tool manufacturing

Paper and printing machinery industry

Hydraulic and pneumatic industry

Aerospace and aviation industry

Mechanical engineering

Railway and rail vehicles industry

Fittings engineering

Precision engineering, mechatronics and optics

Telecommunication industry

Furniture industry

Apparatus engineering

Drive and gear engineering

Building, agricultural and forestry machinery manufacturing

Special purpose machinery manufacturing

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.