Viglienghi srl

Contacts

Kerstin Wrede

Commercial management

Phone:

E-Mail:

Competencies

Parts (2)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1000 - 50000 | 5 - 100 | - | - | 1.5 - 60 | - | - |

Automatic turning (bar) | 1000 - 50000 | 5 - 100 | - | - | 1.5 - 60 | - | - |

Swiss turning | 1000 - 50000 | 5 - 100 | - | - | 1.5 - 50 | - | - |

Full-range turning (including milling) | 1000 - 50000 | 5 - 100 | - | - | 1.5 - 60 | - | - |

Hard turning | 1000 - 5000 | 5 - 100 | - | - | 1.5 - 60 | - | - |

Company description

Viglienghi Srl has been synonym for excellence in manufacturing mechanical precision turned components for more than forty years. Founded in 1970 in Esino Lario, today the company employs the most modern technologies for mechanical processing of INOX steels and superalloys, as well as of brass, aluminium and plastic materials. In 1991, after completing the construction of a modern industrial factory having a covered space of 600 m2, the operative unit is moved to Via dell’Artigianato 3, still in Esino Lario, with its six employees and its machinery wholly converted to CNC technology. In 2002 the factory is enlarged by acquiring the adjacent factory, and reaches a covered space of 1000 m2. In the same year ISO 9001 quality certification is achieved. In 2004 the founder partners retire definitively and the company management is taken over by their son Giovanni Viglienghi, current majority partner, who had already joined the company in 2002, and their daughter, Cristina Viglienghi. A new expansion phase begins, labour force totals 15 employees with a clearer differentiation of company functions, the machinery is renewed and enhanced, the company opens to foreign markets, EU and Extra-EU. In 2014 the company is transformed from a partnership into a limited liability company and the works for building new administrative premises and redefining internal spaces are started. Today the company has 25 employees and is extended over a 2000 m2 area of which 1400 m2 are covered: 1100 for manufacturing, 200 for raw material storage and 100 as administrative offices. Viglienghi Technologies Our many years of experience in mechanical processing (turning, milling, broaching, tapping, cutting, etc…) of INOX steels (AISI 303, 304, 316, 316Ti, 431, 630-17 4 Ph) and of super-alloys, as well as of brass, aluminium and plastic materials, supported by the best technologies, by an accurate selection of the best raw materials, by continuous controls throughout the processing phases, enable us to attain a high level of precision in the products with which we have achieved a consolidated appreciation from the market. FEASIBILITY ANALYSIS We ensure our customers are provided with a consulting service deriving from the vast experience accrued in this mechanical sector. PRODUCTION We have 7 CNC fixed head lathes, bar passage from dia. 5 mm to dia. 60 mm, which enable to work simultaneously with 2 tools reducing cycle times; 7 CNC sliding headstock lathes, bar passage from dia. 1,5 mm to dia. 40 mm, with motorized tools for manufacturing complex and small-size particulars; 3 CNC multi-spindle lathes bar passage from dia. 8 mm to dia. 40 mm: 3 turret lathes with gantry loader for finishings bar passage up to 200 mm; 2 four-axis vertical machining centres; 1 fillet rolling machine. Furthermore, our range includes various turret milling machines, assembly machines, metal parts washing devices, mass metal finishing and polishing systems (sandblasters and tumbling machines). Our manufacturing batches range from 100 to 500,000 pieces, and, on demand, we perform samplings and pre-series. QUALITY INSPECTION Precision is our strength. All our products rigorously undergo controls (optical, contact friction, SPC, …) and are accompanied by a conformity certificate. For every first shipment we perform a measurement certificate and, in some cases, we also work in FREE PASS MODALITY. Warehouse We are structured for stipulating framework agreements to manage a warehouse.

Machines (4)

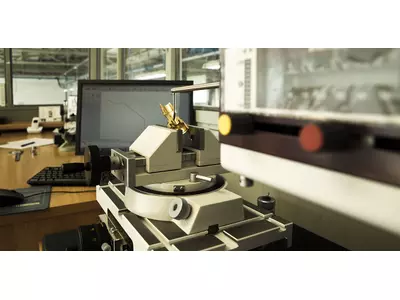

Copmany images

Materials

Plastics/synthetic materials

Thermoplastics

Light metals

Aluminium and aluminium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Industries

Hydraulic and pneumatic industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.