Assembly jigs: Techpilot - free for buyers

Discover specialized suppliers for assembly jigs on Techpilot. Our platform connects buyers with suppliers who manufacture customized jigs for precise assembly. Use the e-sourcing process to find the best suppliers.

711 suppliers for Assembly jigs

We are a modern company in the field of metal processing and manufacturing technology to offer you the highest level. With this philosophy, we provide the expertise, perfection and high reliability to meet your needs. Since 1987, the company produced Klug manufacturing technology products from metal and plastic. Satisfied customers were and are always the ultimate goal. To achieve this, we are constantly working to expand our manufacturing capabilities and to improve the quality of our manufacturing technology. Through many years of experience and with a dynamic team, we respond quickly and flexibly to your specific and exacting requirements. Visit us at: www.ftklug.de

Founded

1987

Employees

10 - 20

Certifications

Stockstadt

Germany - 63811

Your competent partner in the field: Turning - Milling - Grinding Whether item or series production, we deliver the highest precision. Find out about our manufacturing capabilities, we can also solve your intended Zerspanungsproblem. The company Günter Becker is in Osterode am Harz for over 30 years. Until the early 70s, the main business focused on the development and production of automatic wire bending machines for electronic components such as resistors and transistors. After introduction of semiconductor technology made the switch to using pure contract manufacturing in the field of turning, milling and grinding. In this segment, we were not able to establish ourselves in the last southern Harz region through our quality work and numerous attract customers. For our customers today include well-known companies from all industries, including medical, aviation and aerospace technology, automotive industry. We would be happy if we may this also includes you soon! Services ... Our range of services includes: • Item and serial production • Processing of customer parts according to drawing or sample • procurement of materials with test certificate • Installation of smaller assemblies • Delegate of third party services, such as heat and surface treatment, to competent partners • CAD Drafting according to DIN • Final inspection We process almost all materials such as: • aluminum alloys • Steel • Rust-and acid-resistant steels • Titanium alloys • Plastics • Chrome-nickel alloys • and much more ...

Founded

1970

Employees

< 5

Certifications

Osterode am Harz

Germany - 37520

For decades, we are among the leading companies for punching, pressing, stamping and machining parts as well as assemblies. Our production facilities are located in Wildenberg and herb home at the Jagst and in Surany, Slovakia. To manufacture the parts presses are used with benefits 8-630 tons. We process steel, carbon steels, aluminum, stainless steel and non-ferrous metals in material thicknesses of 0.1 mm up to 18 mm and in bandwidths up to 1,000 mm. To pre-production testing of newly developed products, our prototype produces the corresponding prototypes, small series or unique pieces. In the company's own tool we implement your request to precisely and also in the quality you can expect from us in detail. For series production complex stage, progressive and transfer dies are used. A mechanical finishing of all products is possible in our turning and grinding. Our hardening also provides several ways to highly stressed parts post-treat. Convince yourself of our performance and quality.

Founded

1921

Employees

200 - 500

Certifications

Wildberg

Germany - 72218

1. Design - design of stamping tools for sheet metal parts - SW - Siemens NX, SolidWorks, Visi, AutoCAD - progression, tandem and transfer tools 2. Tool shop - CNC milling, electroerosion, grinding - prouction of tools and dies - manufacture of precise machine parts Max. tool lenght 4000 mm, max. weight 30 tons. 3. Press shop - progressive machanical crank presses, press power 500-8 000 kN - sheet material thickness 0,5-4 mm - stamping of parts for the automotive industry

Founded

2000

Employees

50 - 100

Certifications

Vizovice

Czech Republic - 763 12

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Professional support in planning, design and production in mechanical engineering and precision engineering.

Founded

2012

Employees

< 5

Certifications

Söchtenau

Germany - 83139

Founded

2017

Employees

20 - 50

Certifications

Bursa

Turkey - 16140

Our company focuses on small batch and prototype production. We are capable to deliver parts and equipments from metal, according our manufacturing capacity and your technical documentation in proper time.

Founded

2018

Employees

5 - 10

Certifications

Brno

Czech Republic - 60200

In the almost 300-year history of the company, our ancestors have experienced many ups and downs. Today we produce high-precision tools for die casting and injection moulds, measuring and testing gauges, but also small and medium series of compinents, which have partcular and challenging details. We are constantly working to keep our company fit for the future through innovation and further development at both the process and employee levels. That is why we work with an automated cell to which two HSC milling machines and a measuring and an EDM machine are connected. We also have various other technologies in-house, such as 5-axis machining centers, wire erosion machines and grinding machines.

Founded

1733

Employees

10 - 20

Certifications

Bozen

Italy - 39100

With our extensive expertise and many years of experience, we offer you professional solutions in the areas of CNC turning, CNC milling and welding as well as tailor-made mechanical engineering and construction.

Founded

Employees

5 - 10

Certifications

Huisheim

Germany - 86685

About AGS Automation Greifsysteme Schwope GmbH. AGS Automation Greifsysteme GmbH, supplies the industry the industry with high-quality gripper construction solutions and pursues the philosophy "Everything ingenious is simple". Three business areas are at the centre of AGS's activities - 1.) the modular gripper system 2) Customised complete grippers and 3) Automation solutions. The modular system, which currently has over 2500 parts, is constantly growing and remains compatible with competitor products. It is based on the positive-locking slot clamping profiles that are widely used on the market. elements such as gripper fingers and suction cups. The PreciGrip prism system, a world first presented at the beginning of 2011, represents a functional advancement. Faster and more precise to assemble, it is the alternative to the previous profile system. Numerous components that have been improved in detail make the AGS modular gripper system particularly user-friendly. Customers who have a gripper system built for their production situation receive a product from AGS that is still orientated towards the standard, but whose innovative details provide productive advantages in practice. AGS GmbH currently employs 45 people.

Founded

2009

Employees

20 - 50

Certifications

Bergisch Gladbach

Germany - 51429

In 1979, Josef Schmid, the company Schmid Kunststofftechnik. Focus is the manufacture of injection-share of thermoplastics. Production processes and production methods have been and are constantly being improved and renewed. The only way to meet the demands of our customers and make attractive offers. Meanwhile, the production area covers more than 6000 m² and about 75 qualified employees guarantee a reliable production process with secured high quality standard. We are your partner in plastic injection molding and mold making. Preparation and maintenance of the tools are applied to a part of the company's own tool. Through continuous expansion of technology and personnel, we are able to quickly and easily carry out repairs and modifications. We manufacture multiple tools for the production of small parts as well as forms for large molded parts. To produce tools precisely and economically, we are of course with CNC milling machines, CNC lathes, grinders and other machines equipped., It also includes work such as cutting / EDM and laser cladding to our techniques. Injection molding machines for large parts of 1000 t and 1300 t clamping force; Automated with removal handling, weight control and imprinter your products are already checked during the production process and completed. In our machines we can produce plastic parts up to a weight of 7,500 g. Thickness Holme take on the high closing forces and provide the necessary stability of the machine.Constant water temperatures ensure optlimale tempering the tool. The molding compositions can be cooled so controlled. Our machines can accommodate tools up to 20 tons .. Few companies are equipped with machines of this size. By investing in the future more of these machines in the company are already present. Finishing at a glance: -Screen printing -Tampondruck -Heißprägen -Schrägprägen -Ultraschallschweißen -Heizelemtschweißen -Baugruppenmontage Translation by Google Translate

Founded

1979

Employees

50 - 100

Certifications

Obergünzburg

Germany - 87634

Founded

1999

Employees

5 - 10

Certifications

Brehna

Germany - 06796

Founded

Employees

10 - 20

Certifications

Csorna

Hungary - 9300

The mbw group, which has been active on the market since 1987, has developed into a leading and reliable provider of galvanic surface treatment. Thanks to our experience, we can offer you a service model that covers the complex needs of metal finishing. We develop innovative coating systems in cooperation with our well-known customers from the automotive, construction, fittings and electronics industries. The reconciliation of an optimal ratio of the often difficult to reconcile requirements for optics, corrosion protection, functionality and service represents our core competence. With 6 production sites in Germany we underline our reliability and the proximity to our customers. This is one of our corporate goals and enables us to react quickly and flexibly. The service portfolio is rounded off by the metal and fixture construction division, based in Baden-Baden.

Founded

1987

Employees

200 - 500

Certifications

Rheinmünster

Germany - 77836

Plastic injection molding is our world. Amper-Plastik develops and produces high-quality, technically sophisticated plastic products and injection molds for a wide range of industries. And we have stood for quality, innovation and precision for 60 years. Benefit from our extensive know-how.

Founded

1960

Employees

100 - 200

Certifications

Dachau

Germany - 85221

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Aluminum can get forged? YES! Umformtechnik Radebeul GmbH specializes in drop forging parts made of aluminum. Design and construction of the tooling as well as mechanical machining are done quasi in house, using modern CAD/CAM equipment and up-to-date machinery. The Know-how of our personnel guarantees a solid, rapid, and professional handling of your welcomed orders. Depending on customer preference, we can initially create aluminum prototypes. We have 7 friction press machines with a press capacity of up to 16,000 kN available. Work pieces with up to 7 kg blank weight can be manufactured. A final treatment of the forged parts is optional. Chemical etching with sodium hydroxide or blasting with corundum, glass, aluminum or stainless steel balls gives the parts a special surface finish, which serves as the base for further surface refinement. We serve the automotive industry (2-wheel and 4-wheel) as well as manufacturers of valves, electrical fittings, awnings, solar technique, alpine sports industry and many others. We are happy to deliver small (less than 100 parts per year) as well as large (several hundred thousands per year) amounts. Efficiency and Flexibility . Our qualified and highly motivated team works diligently to realize customer requests on time. Manageable costs and high quality construction standard of the products are the basis for the long term prosperous relationship with our customers and suppliers. Expertise We are known for our ability to recognize and realize the goal of the customer through our varied experience , supplemented with the engagement of our professionals and the existence of controlled processes including well-engineered technologies. Raw Material . The selection of available alloys has increased significantly during the last several years because of the growing demand and resultant technological advances. We are therefore in the position to select the alloys best suited for the planned application of your products. A Hard Nut to Crack? Challenge us! We will Forge Your Future!

Founded

1997

Employees

100 - 200

Certifications

Radebeul

Germany - 01445

Founded

1900

Employees

100 - 200

Certifications

Bischofsheim/Rhön

Germany - 97653

Welcome to the exon GmbH Your partner in the areas of: Laser cutting Plasma cutting Sheet metal working Industrial Coating Baugruppenfertigung Welding Mounting Business Using the latest technology and innovative cutting solutions we provide to our customers high quality and reliable services you can not provide themselves because of their corporate structure. Here, our editing program ranges across all materials, because thanks to the latest laser technology we are able to not only process almost all metals but also materials such as plastic, wood, or quartz able. In metalworking our processing spectrum ranges far beyond mere laser cutting out. Thanks to powerful interconnected companies and partners we are able to offer you a full service in metalworking, which goes beyond the mere Processing for assembly, painting and final assembly. We work according to the motto "miracle we do immediately! For the impossible, we need a few days!"

Founded

2004

Employees

10 - 20

Certifications

Bautzen

Germany - 02625

Welcome to Erdel Engineering Your partner for concept development, design and manufacture of mechanical components and assemblies.

Founded

2020

Employees

< 5

Certifications

Berlin

Germany - 12589

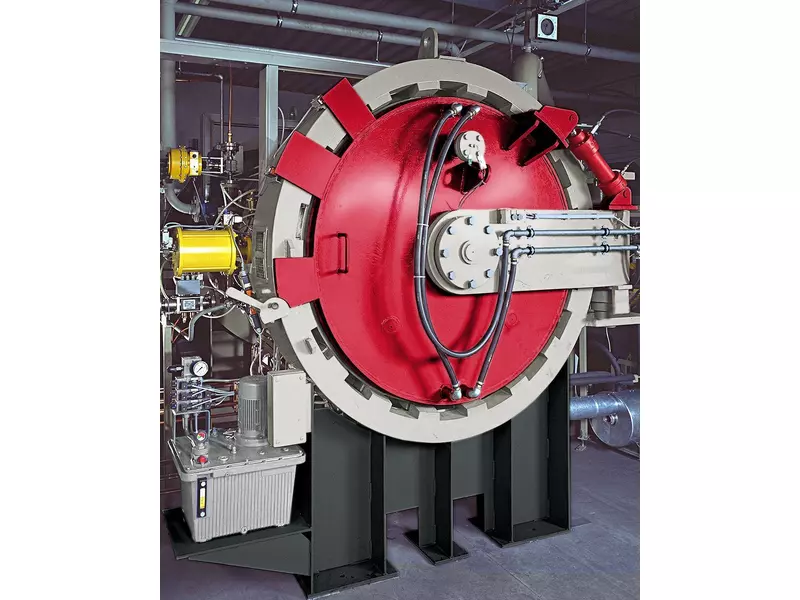

The foundation of TISOMA Anlagenbau und Vorrichtungen GmbH was in 1996. The demand of our client forms the center of our work having as motto: undefined The client does not want the explanation, but the solution of his problems. The base of our capabilities is is our highly qualified personnel. We are in the position to serve with our staff members the following fields of business. Fields: Hard metal - powder injection moulding - sintered metal - ceramics, paints - other applications * Industrial furnaces - vacuum + inert gas * Sinter-HIP-Furnace up to 100 bar * Special equipment for the manufacture of hard metal - Vertical boring and turning mill to maching green bodies - Powder handling - Powder cooling - Others according to customers' requirement specifications * Machines and equipment for powder metallurgy - Mills equipped with agitator - Ball mills - Drying of suspensions * special machines * Fixtures

Founded

2003

Employees

20 - 50

Certifications

Barchfeld-Immelborn

Germany - 36456

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge