Bending and forming: benefit from efficient e-sourcing

Find specialized suppliers for bending and forming on Techpilot. Our platform offers access to suppliers who use modern technologies to manufacture precise and complex components. Benefit from an efficient e-sourcing process and better purchase prices.

2025 suppliers for Bending and forming

Disentis in Graubünden mountain world: Where other people go on holiday, arise in our modern, efficient work "ideas in metal" from design to manufacture high quality product. Our experienced team of specialized and motivated staff is proud to vouch for versatility with the highest precision. " Toolmaking: High-performance hot runner molds for the processing of technical thermoplastics and thermosets | injection molds for the processing of technical thermoplastics and thermosets with all gate systems | Pressure die casting molds for the processing of aluminum, zinc and magnesium | punching & bending tools for the processing of steel, aluminum, copper, etc | Our mold & mold sizes include: injection, punching bending & die casting tools from 96x96 to 596x596 mm | Sampling: We sampled at the customer's injection molds up to a closing force of 950 KN. Machining Highest accuracy in the production of small and large series is self-evident for us. Thanks to modern machinery and high quality tools we achieve a highly favorable cost - benefit ratio. We process: series of 5 to 50,000 pieces of steel, aluminum and non-ferrous metals up to 1000 x 650 x 500 mm. Component technology Co-development, prototype manufacture, fabrication of parts, procurement of commercial goods and electronics, as well as the installation, the wiring, final inspection and shipping worldwide. Punching and bending technology With our unfassenden know how we can make even the most demanding customers satisfied eg in the electronics industry. Thanks sophisticated tool technology, we are able to punch in one step, turn and rivets. With machines up to 70 tons we process all materials between 0,01 and 4,0 mm. Thermal and surface treatments are carried out in our responsibility. Coil fabrication Through our manufacturing experience and meeting deadlines, we can meet the high demands of a large number of customers worldwide meet. In our manufacturing centers, we process: round wire 3-5 mm, imTakt of approximately 10 pieces per minute. Rectangular wires of 3.15 x 7.1 x 0.6 mm to 5 mm can be edited manually.

Founded

1988

Employees

50 - 100

Certifications

Disentis

Switzerland - 7180

Our company manufactures forged and machined parts up to 10 Kg weight. It is Tier 1 supplier and is usually involved in product development by the customer. It is certified IATF

Founded

1956

Employees

50 - 100

Certifications

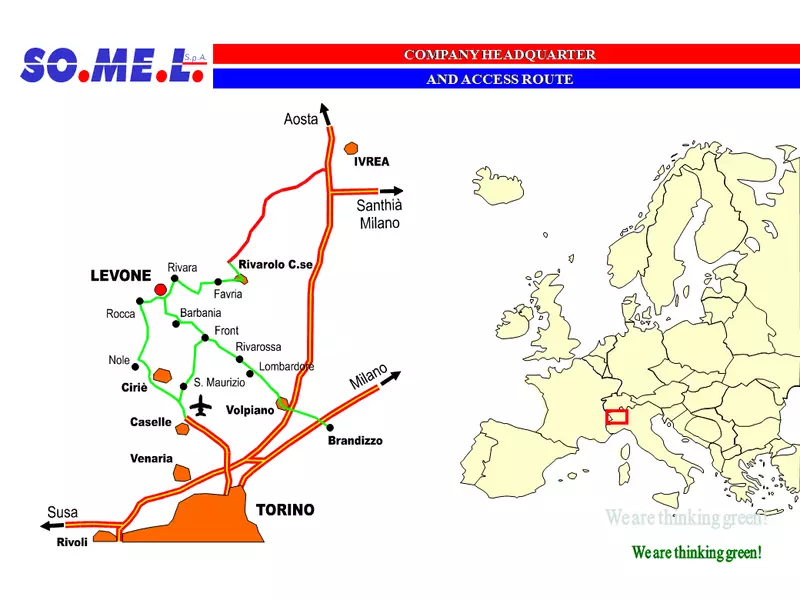

Levone (Torino)

Italy - 10070

Service for device from the middle of Germany With modern technologies locally and trained staff, we support our customers' ideas. We are able to design and develop products according to customer specifications further in the engineering design. Our production range goes from the cutting and non-cutting production to the manufacture of CNC machined parts, stampings, CNC laser parts, CNC bending, welding assemblies as well as complicated and high-quality sheet metal parts and sheet metal structures, machine covers, racks, sheet metal enclosures, cabinets, assembly groups in steel, stainless steel, aluminum, copper bus bars, etc. completely from prototype to mass production including the desired surface coating (eg, powder coating, wet painting, silk screening, etc.), gasketing and assembly. You get full service with short delivery routes from the center of Germany - that saves time, reduces your costs and protects your nerves. Short term, we have spare capacity to run our cleaning and degreasing. The system works both in the spraying process and also in blowing off the parts to be cleaned with air. To clean aqueous cleaners can be used. Ideal for high volume regardless of whether geometry transmission parts, engine parts, drive shafts or plastic crates and baskets. Our quality management system is through the - certified "DQS German Association for Certification of Management Systems" according to the standard DIN EN ISO 9001:2008.

Founded

1938

Employees

50 - 100

Certifications

Arnstadt

Germany - 99310

Our company focuses on small batch and prototype production. We are capable to deliver parts and equipments from metal, according our manufacturing capacity and your technical documentation in proper time.

Founded

2018

Employees

5 - 10

Certifications

Brno

Czech Republic - 60200

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1997

Employees

5 - 10

Certifications

Heilbronn

Germany - 74081

Nanni Ottavio Srl Your partner for precision carpentry in the woodworking machinery sector. In the heart of Emilia-Romagna, a land renowned for its industrial and artisanal excellence, stands the company Nanni Ottavio Srl, a bastion of innovation and tradition in the processing of metal carpentry for the woodworking machinery sector. Founded in 1989 by Ottavio Nanni, the company began its journey collaborating with important clients such as SCM, a giant in the wood machinery sector, and then expanded its clientele to other prestigious companies. The story of Nanni Ottavio Srl is a story of growth, innovation and dedication, constantly investing over time in cutting-edge technologies that have allowed the company to work with a wide range of metals such as iron, stainless steel, aluminum, copper and brass. This commitment to innovation has allowed Nanni Ottavio to specialize in precision machining such as the production of harmonic steel dividing knives, carpentry for special electrical boxes, external covers for automatic machines, metal brackets and medium-small frames, becoming a leader in the Italian market in these automatic and manual woodworking machines for me. The 2000s marked a period of significant growth for the company, culminating in the opening of the second production plant in 2020 in Longiano. This development has further consolidated Nanni Ottavio's position in the Italian market, offering solutions for a wide range of machines such as carpentry machines, circular saws, cutters, planers, universal combined machines, edge banding machines, CNC drilling centers, and many others. The ability to adapt, combined with a constant commitment to innovation and quality, has cemented the reputation of Nanni Ottavio Srl as a reliable partner and a leader in its sector. PLUS: 1. High Level of Specialization: For over 30 years, Nanni Ottavio Srl has represented a symbol of quality and specialization in metalworking for woodworking machines. Our deep experience and expertise are reflected in every product we make — from harmonic steel divider knives to special electrical boxes, from external covers for automatic machines to metal brackets and medium and small frames for woodworking machines. 2. Full service: We offer a complete service that starts with your project and ends with a finished product. Our team works closely with you to transform your drawings and projects into high-quality finished products. With the capacity to handle more than 24,000 order lines per year, we specialize in the processing of iron, stainless steel, aluminum, as well as copper and brass. 3. Timely responses and deliveries: Nanni Ottavio Srl undertakes to provide timely answers and deliveries, whether they are large series productions or individual batches. We understand the importance of timeliness and precision in the industry and are proud to consistently meet these expectations. 4. Multilingual sales office: Our sales department speaks your language — literally. With a team that speaks fluent English, German and French, we ensure smooth and effective communication to meet your needs and answer your questions

Founded

1989

Employees

20 - 50

Certifications

Savignano sul Rubicone

Italy - 47039

in the GTS ter Schmitten GmbH & Co. KG. Since 1988 we have been operating successfully as a service company in the commercial kitchen industry. Also, our range of machining technology has been represented for years as an established supplier to companies trying various sectors in the market. On our website we want to give you an insight into our performance catalog.

Founded

1988

Employees

10 - 20

Certifications

Gelsenkirchen

Germany - 45879

Carpentry specialized in sheet metal processing for third parties. Thanks to the solid experience in the sector and the continuous technological updating, it is able to supply products on drawings or models supplied by customers, with particular attention to the choice of materials up to the finishing treatments. A qualified assistance to customers in the process of developing their own products, prototypes and production, makes it collaboration is precious.

Founded

1993

Employees

10 - 20

Certifications

Capriate San Gervasio (BG)

Italy - 24040

With our extensive expertise and many years of experience, we offer you professional solutions in the areas of CNC turning, CNC milling and welding as well as tailor-made mechanical engineering and construction.

Founded

Employees

5 - 10

Certifications

Huisheim

Germany - 86685

MEZ GmbH

The fusion of an experienced manufacturing specialists of machinery and plant with a renowned development center gives the customer the ultimate Benefits: All services under one roof. From the idea to the final assembly by running your product has a clearly structured and manageable development process at any time. In which all parties merge their knowledge and skills into a harmonious whole. The customer is our top priority and determines the solution-oriented thinking and acting of the entire company. Dedicated, flexible people in interaction with current software and the latest manufacturing technology to see the buyer's duty as a challenge that they face you. Set to optimum effectiveness and cooperate with a competent system partner.

Founded

1875

Employees

50 - 100

Certifications

Reutlingen

Germany - 72770

TPV AUTOMOTIVE D.O.O https://www.tpv-automotive.si/en/ CORE PROGRAMMES - R&D SERVICES - COMPLEX SURFACE PROTECTION - ALUMINUM STRUCTURES - HIGH STRENGHT STEEL COMPONENTS - AGRICULTURAL AND CONSTRUCTION EQUIPMENT Brief description of equipment - Stamping on a press with forces from 60T - to 2500T - KTL surface protection, the largest size 3,000 x 800 x 1,500, weight 600kg - Laser cutting of the largest size 4065 mm x 2035 mm, laser power 12,000 W, panel cutting up to 30 mm thick - Hydraulic bending on a bending machine, maximum force 2200kN, maximum length 3000mm - Welding MIG, MAG, FSV, spot, classic manual and robotic welding Jože Pečavar Skrbnik ključnih kupcev/ Key Account Manager Prodaja/Sales TPV AUTOMOTIVE d.o.o. Brezina 101 SI-8250 Brežice, Slovenija Gsm: + 386 (0)31 701 768 Skype: joze.pecavar www.tpv-automotive.si

Founded

1989

Employees

500 - 1000

Certifications

Brežice, Slovenija

Slovenia - 8250

We are a medium-sized operation of the spring industry in Schwabach, Middle Franconia and present us today with approximately 70 employees as a traditional and competent manufacturer for technical springs and bent parts made of steel, stainless steel and non-ferrous metals of special solutions to large-scale production. Innovation is backed by expertise in Lohr GmbH & Co. KG precision springs. Know-how is the reliance on experience and the anticipation of the latest development. Innovative solutions need both. Take advantage of our experience, our knowledge our quality and delivery reliability. Manufacturer of springs * Compression springs * Extension Springs * Torsion Springs * Punch -., And bent parts * Wire bending parts

Founded

1952

Employees

50 - 100

Certifications

Schwabach

Germany - 91126

1. Steel work constructions and Fabrications: Can be produced in all weldable grades of steel, stainless steel and aluminium. 2. Ferrous Castings: Generally available with a range of alloy material choices including SG cast iron and cast steel in the range of 0.5 to 500 kg. 3. Non Ferrous Castings: Available as gravity or pressure cast components in typical alloy compositions. 4. Profiled Components: A wide range of cut and formed components can be manufactured in a variety of finishes. Components can be cut to a high degree of accuracy using the most up to date laser technology. 5. Forgings: Steel forgings are generally up to 50th's in applications where internal cavities are not required. 6. Treatment and Finishes: All products can be provided as produced or as heat treated products and where required can also be supplied in a range of finishes.

Founded

2011

Employees

20 - 50

Certifications

Iasi

Romania - 700381

SOME Stamping Solutions is an industrial company offering a wide range of manufacturing services related to sheet metal forming, such as: deep-drawing, stamping, folding, CNC punching, laser cutting, welding, rivetting or assembling. SOME Stamping Solutions consists of 2 business units: 1. SOME Automotive: TIER 2 supplier specialized in manufacturing car parts for safety belts and airbags, among others. 2. SOME Industrial: sheet metal forming services for highly demanding industries such as: medical equipment, railway, IT, HVAC or home appliances. SOME Stamping Solutions headquarters and main manufacturing plant are located in Spain (one hour drive from Barcelona). SOME KSW is located in Poland.

Founded

1973

Employees

200 - 500

Certifications

Sant Quirze Besora

Spain - 08580

Founded

2010

Employees

5 - 10

Certifications

Zemite

Latvia - LV3135

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are an engineering company that deals with complete engineering production. Material separation, welding, drilling and thread cutting, sheet metal processing (cutting, bending), CNC machining, surface treatment. Steel and stainless steel covers, machine parts, structures and parts according to customer requirements are our product. First-class quality, professional approach, price, delivery date and all agreed conditions are important to us, which is also confirmed by the ISO 9001 certificate.

Founded

Employees

5 - 10

Certifications

Košice

Slovakia - 04001

Founded

1999

Employees

50 - 100

Certifications

Istanbul

Turkey - 34785

We offer you - CNC milling and conventional milling - CNC turning and conventional turning - CNC wire EDM - Processing 2D and 3D files using CAD/ CAM - Manufacture of all types of sheet metal parts - welding of steel, aluminum and stainless steel - Prototyping - laser cutting - Watersteel cutting - surface grinding

Founded

1995

Employees

5 - 10

Certifications

Braunschweig

Germany - 38112

As Alsa Çözüm Metal, we are honoured to serve our valued customers with our experienced staff and wide production facilities. Materials you can request from us : -stainless steel sheets,coils,pipes.tubes,bars.angles -steel sheets,coils,pipes,tubes,bars -aluminium sheets,coils,bars.tubes,pipes -Pe300,Pe500,Pe1000 sheets and bars Services you can request from us : -Laser cutting up to 100 mm for metals -Water jet cutting -Bending -5 axis machining -Welding -Painting -Coating

Founded

2014

Employees

50 - 100

Certifications

Bursa

Turkey - 16110

The NSG NAKAGAWA + SAUER & CO. GMBH is a reliable partner for mufflers and heat and sound insulation using glass and stainless steel fibers. The company values the use of high-quality materials to ensure the best results and customer satisfaction. It is certified in accordance with IATF 16949:2016 and ISO 9001:2015 and therefore offers high quality standards worldwide. The head office is located at Staxstraße 1 in 74921 Helmstadt-Bargen, Germany.

Founded

1997

Employees

10 - 20

Certifications

Helmstadt-Bargen

Germany - 74921

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge