Deep drawing: receive an avg. of 7 offers per request

Discover specialized suppliers for deep drawing on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to create high-quality deep-drawn products. Use the e-sourcing process to find suitable suppliers in real time.

421 suppliers for Deep drawing

Gebr Wagner D-90584 Allersberg The company Gebrüder Wagner looks back on decades of experience in stamping technology and is appreciated by its customers as a reliable partner. Efficient, cost-effective and of the highest quality, we supply almost all industrial sectors. Our company is always ready to adapt to the latest technology and happy to accept the suggestions of its customers true to jointly accomplish tasks. Our scope of services: -Stanz-/Biegeteile To 4 mm Pressing force up to 450 Small and large series of all metals Prototypes -Mechanical Assemblies Robot welding CNC Milling Wire erosion -House tool Punching technology for over 60 years We will send you our company brochure or to make us love you to inform you.

Founded

1946

Employees

50 - 100

Certifications

Allersberg

Germany - 90584

We support you from product idea to economic product implementation. We focus on competent advice and the development of cost-effective alternatives. Our quality awareness in accordance with DIN EN ISO 9001:2000 is the focus of our daily work. Even when developing products, we pay attention to progressive and sustainable documentation. Production and surface protection of fan covers and ventilation systems for general mechanical engineering, commercial vehicles and railways as well as steel furniture and ship window boxes for seagoing ships and stationary systems.

Founded

Employees

20 - 50

Certifications

Bremen

Germany - 28755

ZIAS is an international group of companies, which is represented in Germany with ZIAS International GmbH in Darmstadt. Our production is flexible and can operate various jobs in metalworking, which uses the following technologies: turn mill punch roll To bend To cut heat treatment grind extrusion Polymer powder coating welding galvanizing hardening From the production of building profiles to manufacturing precision parts for the medical, aerospace, tools for production machines and entire automated systems and equipment - all the strengths of ZIAS are. Qualified ZIAS staff in all areas ensure the quality of products and ensure timely order processing.

Founded

Employees

200 - 500

Certifications

Darmstadt

Germany - 64291

Founded

1976

Employees

10 - 20

Certifications

MANDELLO DEL LARIO (Lecco)

Italy - 23826

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are an ISO-certified sheet metal processing company, is under Swiss leadership since 1989. ISO certification since 2000 ISO 9001:2008 Our Kernkometenzen are stampings and laser parts, and a combination of laser parts and stampings. Thus, we can manufacture and install complete assemblies. Stampings: In-house tool with 2 Drahterordiermaschinen. 13 punching machines 32-200 ton press force We punch of 0.2 mm to 8 mm thick band gap Loading presses from 20 to 400 tons of pressure On the Insert-C-presses, we also process tubes and profiles Our insertion presses are used for assembly work. Our Periferiemaschinenpark is equipped with, riveting machines, resistance welding machines, tapping machines, drilling machines, Richtwerk HRC, welding items MIG, MAG, TIG, stud welding, Aluminiumprofilsäge Laser parts: 4 laser cutting machines, 3 and 1 flat laser tube laser 1 flat laser 30 KW, 1500 x 3000 mm working area 1 flat laser 4.4 KW, 2000 x 4000 mm working area 1 flat laser 3.5 KW, 3000 x 6000 mm working area Brakes to 4100 mm length and 250 tons press force Assembly of components We now offer our catalog of products on our e-commerce site www.quincaillerie-en-ligne.com. We employ 65 staff and process approximately 3000 tons of steel sheets a year. Since 1999 we are in the neighborhood Plessier, Bâtiment 10 in F68130 Altkirch in our new building of 5000 m2. Altkirch is located about 25 Km to Germany and Switzerland

Founded

1923

Employees

20 - 50

Certifications

Altkirch

France - 68130

In the precision engineering, we are the right partner for your pattern and prototype manufacturing. Whether prototypes contact parts or semi-finished products - we make your wishes for different industries: automotive and electronics industries as well as home appliances and communication technology. In addition, we are using our products in important sectors such as hybrid and solar technology represented

Founded

2001

Employees

5 - 10

Certifications

Messel

Germany - 64409

Founded

1994

Employees

20 - 50

Certifications

Vlkanova

Slovakia - SK-97631

Since 2002 Firma Tarapata has been specializing in production of metal parts for white appliances, automotive, construction, parts of fire extinguishers and lawn mowers. We offer complex all grades steel processing – hot and cold forming: stamping, laser cutting, welding, bending, powder painting. We ensure the highest quality and on time deliveries. We have experience in high volume lots for big concerns and one-time orders. Jan Tarapata in 2000 invested in next plant located in the Special Economic Zone EURO-PARK Mielec. The company under the name "Firma Tarapata" Sp. z o.o. started its activity in 2002. In 2010 we achieved the Certificate of Business Credibility. Our D-U-N-S number is: 367143299

Founded

Employees

100 - 200

Certifications

Mielec

Poland - 39300

Metalworking and light carpentry -drawing/turning -welding -punching processed materials -iron -steel -brass -aluminum

Founded

Employees

< 5

Certifications

Massanzago

Italy - 35010

Our core competence plastic injection molding is constantly being expanded to include new manufacturing and finishing techniques. These currently range from thermoforming and ultrasonic welding to pad printing, hot stamping, screen printing, painting, ablation- and cutting lasers, (PVD-) metallization up to robot-guided seal foaming and high-gloss polishing, among others. However, our consistent INLINE manufacturing philosophy is unparalleled. With our expertise in automation technology, we can link injection molding directly and fully automatically with all surface finishing and assembly processes, thereby achieving unique process consistency and cost-effectiveness even for small and medium batch sizes.

Founded

1970

Employees

100 - 200

Certifications

Ötisheim

Germany - 75443

For more than 40 years we have been engaged in the design, industrialization and molding of technical articles in both metal and plastic; today Segato is specialized in the construction of structures for desks and complements for office furniture with an elegant and innovative design. Customer involvement is very important for finding targeted solutions and responding at best to his needs. The design is carried out within the company, also in collaboration with designer, architects or technicians. We make use of innovative technologies and cutting-edge equipment, we use quality materials to guarantee a valid and solid product, able to persist for a long time. In the company there are highly trained collaborators, able to respond quickly and precisely to various requests. the care of details, attention to functionality and design are an integral part of our mission which is focused on proposing entirely MADE IN ITALY solutions.

Founded

1977

Employees

20 - 50

Certifications

Fiume Veneto(PN)

Italy - 33080

BRAMP a company with over 30 years of experience - certified to ISO 9001, IATF 16949 and ISO 14001 - is a worldwide reference company in the field of injection moulding and metal processing dedicated to the development of solutions for the automotive, electronics, industrial, appliances and telecommunication sectors among others. Although BRAMP core business is the injection of plastic materials, BRAMP integrates its own resources / capabilities to support all the entire development of the life cycle of a plastic product, namely: Engineering and Commercial Dept. Designing and Development of new products / moulds supported by CAD/CAE software tools; Feasibility analyses and DFM studies of products developed by customers; Rapid Prototyping Unit Prototypes manufacturing by FDM (ABS-M30, PC e PA12); Production / Plastic Injection Dept. Plastic injection by mono, bi and over injection. 67 injection machines with clamping forces from 15Ton to 1.100Ton; 5 of them are bi injection machines; Overmoulding; Assembly lines for sets / products; Quality "wall" Metrology Dept. (internal capability for developing PPAPs) Dimensional control: scanner 3D, 3D coordinates machine and profile projector; Mechanical tests: Tensile machine; Humidity control; Colour control; Durometer for hardness assessment; Others means of control usually available in this industry; Moulds Dept. CNC machining centers (milling and turning); EDM machines; Laser welding; Auxiliary machinery; This unit was created to assure the maintenance, repair and modification of the moulds of our customers but quickly evolved to the internal production of small / medium sized moulds (up to 2 Ton); Metal Processing Dept. Unit for stamping, folding and bending metal sheet for small / medium serial production of metal parts equipped with: Machining centers (X=1000; Y=400; Z=500); Bending / folding machines (dimensions up to 2700mm and 5mm thickness); Punching machines (dimensions up tp 2500x1250 and 3mm thickness); Logistics Dept. 2 trucks that cover national territory and northern Spain; Other situations we work with national / international partner carriers / forwarders

Founded

1993

Employees

50 - 100

Certifications

Braga

Portugal - 4715-533

The company POK doo, has been working in the metal industry for 30 years. We have a lot of know how and offer products from sheet metal and pipes, as for example, chopped bent or drawn on eccentric presses sheet un pipes, up to 2500 KN. CNC processing, punching, bending and laser cutting of sheet metal, steel 20 mm thick, Stainless steel 10 mm thick, aluminum Max 6 mm thick, laser cutting of tubes with the Diameter 20 to 40 mm, maximum total weight up to 200 kg, steel 12 mm thick, Stainless Steel 5 mm thick and aluminum 4 mm thick. We also offer steel, stainless steel and aluminum Alloys Welding job by MIG, MAG, TIG to methods. The products are available either as individual parts or combined parts. The products can be protected at the surface. The products are adapted to your plans and desires, or give to their ideas and we make remaining planning. We offer: -

Founded

1989

Employees

10 - 20

Certifications

Ptuj

Slovenia - 2250

Ostseestaal GmbH & Co. KG is a specialist company for the production and delivery of tailor-made kits made of cut and three-dimensionally shaped sheet metal. The highest quality materials such as steel, stainless steel, aluminum and special alloys such as INVAR etc. are processed. Ostseestaal is active on the world market for shipbuilding, industry, renewable energies as well as for architectural projects. Through our modern machinery and our constantly trained staff, we are able to deliver our products turnkey. Our products are known for their added value. We have the know-how for technical planning and constructional execution of innovative and customized products. We manufacture tailor-made products that fully meet your wishes. Our entire product range meets the highest demands in terms of technology, safety and quality. Our diverse knowledge and skills, along with our passion for our work, give you the competitive edge you seek. Ostseestaal is an integral part of the international group of companies Central Industry Group (CIG), which operates on the world market for shipbuilding and renewable energies as well as for industrial and architectural projects. The Group companies of CIG complement each other; The synergies are part of our individual and service-oriented customer care.

Founded

2000

Employees

100 - 200

Certifications

Stralsund

Germany - 18439

Founded

2017

Employees

500 - 1000

Certifications

Schwanewede

Germany - 28790

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

As a company specializing in the field of metalwork and as a professional powder paint shop, we are able to provide you with comprehensive services. First of all, we deal with production, which for us always starts with an interesting project. We are prepared to create unconventional solutions in accordance with the wishes of the customer, which is perfectly represented by our balcony balustrades. However, that's not all, because as a modern paint shop we also paint rims. We use the most modern methods of applying varnish - we use a powder technique that allows us to thoroughly cover the paint coating even hard to reach places of painted elements. So if you want to order stainless steel balustrades (e.g. balcony), fences, signboards, advertisements, shelves, or have powder painting - e.g. rims - please contact us. We can assure you that we have experience, knowledge, excellent workshop and workshop equipment, as well as qualified staff, thanks to which we can carry out even the most complex orders. Welding, painting, cutting, bending? No problem! We create various types of enclosures, advertising boards, handrails and other more or less complex constructions for our clients.

Founded

2013

Employees

20 - 50

Certifications

Reda

Poland - 84-240

Springfix stands for modern forming technology and machining in large and medium volume production. We supply parts to component suppliers to the automobile, building equipment and electrical industries world-wide. We react flexibly and quickly to our customers’ requests. We view ourselves as being in a dynamic process in which products and services are continuously being developed and improved. Our understanding of "Swiss made" goes far beyond technical reliability. Our modern and material-efficient technology portfolio includes - Demanding conventional stamping up to 4000kN - Re-passing for contour regions of fine blanked parts - Processing of brushed and finished surfaces - Centrifugal and vibratory finishing - Surface degreasing and refining processes - Picking Structured, well documented processes and the latest generation in resource planning tools ensure a precise production process, essential in a multi-shift business. Our task is not completed with the simple production of your parts. To us, on-time delivery and customer satisfaction are more than just the icing on the cake – they are the basis of the type of customer service we envisage. And we offer the logistics standard of today and tomorrow: - Delivery schedules - WebEDI - Vendor Managed Inventory - E-Dec

Founded

1970

Employees

50 - 100

Certifications

Wohlen

Switzerland - 5610

Kiefer GmbH has been producing stamped and bent parts as well as welded constructions of the highest quality for more than 35 years. Our components are used by well-known customers in the automotive, building hardware, sanitary, household appliance and solar industries. With a constant focus on efficiency in all production steps, we are able to deliver the highest quality standards at unbeatable prices. We work steel, stainless steel, light and non-ferrous metals as well as plastics up to 15 mm thickness on modern and efficient machines. Our in-house tool shop allows us to quickly and professionally realize even short-term orders. Technical Equipment: - 2 punching machines - 35 eccentric and hydraulic presses with up to 400t pressure capacity - 4 multi-spindle drilling machines - Thread cutting machines - 8 welding workstations (MIG, MAG, TIG and resistance welding) - 2 welding robot systems - 2 high performance metal sawing machines - Own toolmaking

Founded

1983

Employees

50 - 100

Certifications

Biedenkopf

Germany - 35216

Since 1971 OTIM provides custom sheet metal stamping services, including blanking, deep drawing and bending for various industrial sectors: automotive, industrial air conditioning, electromechanical, construction and household appliances. Starting from the drawing or from a prototype, Otim is able to follow the design and construction of equipment and details, covering the entire process of product industrialization and contributing to the optimization of the production process with a costs reduction and a qualitative improvement approach. The machinery includes both mechanical and hydraulic presses up to 400 tons, which allow to produce from the simplest parts to complex processes, also with the use of progressive moulds for large series. The parts can also be supplied complete with assembly, threads, tumbling, painting and with any chemical-galvanic treatment.

Founded

1971

Employees

10 - 20

Certifications

Pedrengo

Italy - 24066

Founded

Employees

5 - 10

Certifications

Frankenberg

Germany - 09669

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

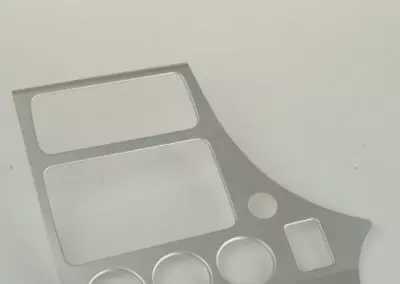

Deep drawing

Deep-drawing is a part of Sheet metal processing and the most important forming method for the production of sheet metal parts. According to the definition of DIN 8584, it is tensile compressive forming and the processing is carried out by simultaneous tensile and compressive stress in different operating directions. The drawing method most commonly used is deep-drawing with rigid tools from tool making. The tools consist of a punch, a die and a sheet holder. The sheet metal blank is fixed by the sheet holder and during immersion the stamp spans the sheet in the board across the die radius, pressing it into the die (also called drawing ring). In doing so, the required punch force constantly increases until the dead-centre position is reached. The edges of the punch and the die are rounded, otherwise the sheet might tear. If the roundings are too large, the sheet at the end of the draw can no longer be fixed by the downholder, which may lead to wrinkling. If the draw depth is not reached in a single step, the draw is executed in several steps, especially in case of thick sheet metals.