Drilling milling jigs: get complete market transparency

Find specialized suppliers for drilling and milling jigs on Techpilot. Our platform offers access to suppliers who manufacture customized jigs for precise machining. Benefit from comprehensive market transparency and optimize your supplier selection.

654 suppliers for Drilling milling jigs

We provide complete solutions of systems and devices (with and without structures), tools (sheet metal stamping) and test gauges and special machines of all kinds On our Tebis 2.5 and 3D programming courses, we can create all the editing programs. 2.5 and 3D machining also be run as subcontracting. The mechanical and spatial possibilities for the manufacture and assembly have since been expanded as the know-how. Further, huge investments of new production halls, crane systems, large CNC - controlled milling machines and Horizontalbohrwerken paved the path challenging as an interesting partner to the automotive industry, the press industry and the aerospace technology. Everything from a hand- Hydraulics, pneumatics and electronics round out our catalog of manufacturing options.

Founded

1969

Employees

20 - 50

Certifications

Hardthausen-Gochsen

Germany - 74239

VÝVOJ Martin, a.s. offers services in the segment of design and subsequent production of various industrial equipment. Main areas of design and production activities: Unique machines in accordance with customer needs/specification Various types of containers equipped with technology intended for military and civil use Mobile applications Gear drives Testing devices Operational manipulators for welding Fixtures Hydraulic and pneumatic systems FEM analysis Technical advisory, reconstructions and upgrades

Founded

1958

Employees

100 - 200

Certifications

Martin

Slovakia - 036 01

At Phoenix Maschinenbau, we differ from conventional mechanical engineering companies in that we do not offer our own product range, but provide complete support and implementation of your project. We call it Phoenix Mechanical Engineering Solutions from Engineers and we attach great importance to these statements. In addition, we operate in the entire mechanical engineering sector and are not limited to one sector. Thanks to our large and unlimited variety of resources, we of course also offer our segments individually. Another important point is that, as Phoenix Maschinenbau, we are represented in several cities and regions and can therefore guarantee service independently of the location. The solutions provided by engineers and technicians from Phoenix Maschinenbau are always eager to provide you with technically and economically compatible solutions. Experience has shown us that rarely an office or a company can solve a problem comprehensively. We were born precisely with this idea in mind. We want our customers to get everything from a single source, so the question why is very easy to answer. We will explain the benefits of this to you in very general terms. An inquiry to a design office usually results in something having to be manufactured in production afterwards, and this is where the first time losses and problems occur. Dimensions are missing; the function of components is unclear; errors occur as manufacturers produce blindly according to drawings. What would happen if both were created in one company? Errors that occur are identified before delivery and resolved within short distances. Depending on the scope of the project, this process is very lengthy. Not with us!

Founded

2015

Employees

10 - 20

Certifications

Lünen

Germany - 44536

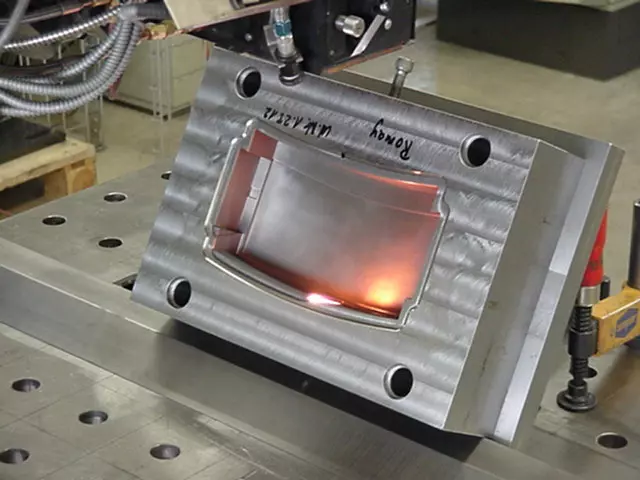

We are a family-run company based in Neuenrade and have over 5 decades of experience in toolmaking. Back then, purely specialized in eroding, we now have a machine park that extends over CNC milling machines with 5-axes, countersinking and wire eroding machines. We manufacture your components in 3D with the Mastercam and Mecanic programs. Our portfolio includes progressive tools (punching, bending, deep drawing), fixture construction, prototype tools, standard parts, etc. We would be happy to support you with our know-how from the idea to implementation, as well as the ongoing production and maintenance of your tool. We always remain your contact! Our team consists of experienced and young dynamic employees. We are characterized by flexibility, high precision and accuracy. We also attach great importance to close communication with our customers in order to avoid problems and reduce downtimes. Often your own capacities are not sufficient for complex tools or individual components, we are happy to step in for you at short notice. Just talk to us!

Founded

Employees

5 - 10

Certifications

Neuenrade

Germany - 58809

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

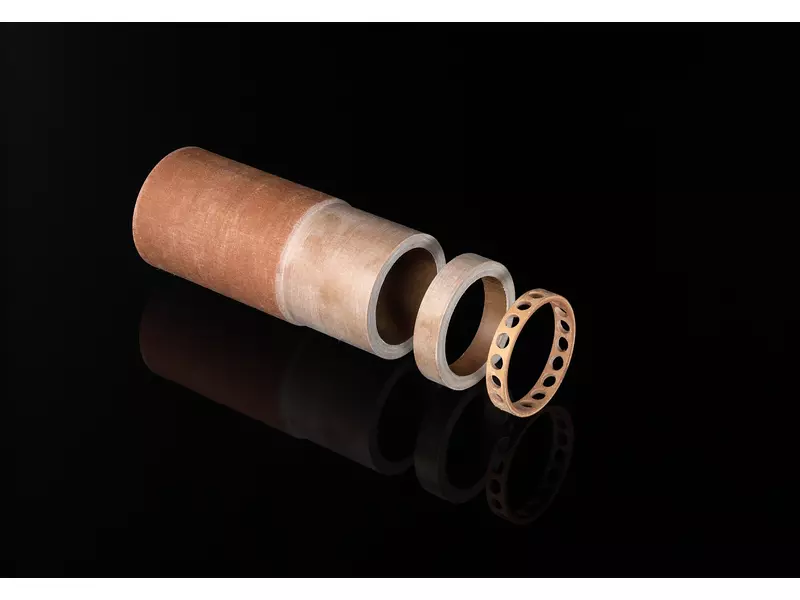

Keppler- Precision Engineering is a successful family business for demanding and geometrically complex components made of thermoplastic materials, high-temperature Plastics and metal injection molded parts in MIM technology (Metal Injection Molding). Innovation, precision and absolute customer satisfaction are for more than 48 years to our corporate philosophy. Our service program includes mold making, construction of customized measuring and test equipment, metal injection molding using MIM technology and the production of precision plastic parts, especially of technically sophisticated and geometrically complex small parts weighing 0.002 to 25 gr. Customers in the medical, electronics, optical industry, measuring and control technology and various fields of precision engineering industries appreciate our precision, quality and punctuality.

Founded

1967

Employees

10 - 20

Certifications

Engelsbrand

Germany - 75331

We are a small company that specializes in small series and very small series as well as single part and prototype production. Our equipment includes a plasma fine blasting system, a water jet abrasive cutting system, drilling, turning and grinding machines as well as welding workstations.

Founded

Employees

< 5

Certifications

Rohrbach

Germany - 85296

Founded

Employees

< 5

Certifications

Gaißach

Germany - 83674

We manufacture installation or storage-finished machine parts according to drawings or samples from all machinable materials. Furthermore, we produce almost any type of gears, milled, or ground encountered. The respective wheel center can be delivered or made by us. Due to our high manufacturing depth which the complete mechanical processing (such as turning, milling, grinding, eroding, clear) covering, a fast and inexpensive for you to order processing is guaranteed. Quality, on time delivery and customer satisfaction are important cornerstones of our corporate policy. All the work we carry out in accordance with DIN EN ISO 9001. One of our strengths is the fastest Production of repair parts, which is ensured by a high flexibility of our employees.

Founded

1937

Employees

5 - 10

Certifications

Berlin

Germany - 13409

Founded

1910

Employees

20 - 50

Certifications

Turbenthal

Switzerland - 8488

We are your specialist for bending, stamping and laser technology. The vision for a new company - according to this principle has already been traded late nineties. In consequence of this was a full-service provider to consistently place customer benefits at the heart of his actions: the door line GmbH. As an efficient specialist in metal processing, the medium-sized company has now successfully established in the market. Three decades of experience in using the latest CNC machining technology - for the Elementebau up to the facade trade - were in favor of the ideal condition. On this basis, the bending, stamping and laser technology developed to the core business of the door line. The current focus is the demanding field of stainless steel and aluminum sheet processing. Manufacturers of different industries use the flexible capacity and the excellent service of the door line teams to strengthen their competitive positions. Whether custom items, prototypes or products: The trimmed on punctuality, precision and top-quality high-tech machine park offers door-line customers in greatest challenges decisive advantages. Current investment in the future: door line generated design-oriented in-house developments, to position itself as a manufacturer. In addition, the new products offer interesting growth opportunities in other markets. The product range already includes prominent families of future-oriented stainless steel and aluminum. The extraordinary appearance in the door line "high-tech" look refined both indoor and outdoor areas. Exclusive design desks and shelving systems, PunchART-Pictures, but also individual, made by Default idea - there is always a smart solution and the creativity of door line behind it.

Founded

1996

Employees

20 - 50

Certifications

Leopoldshöhe-Greste

Germany - 33818

With high productivity and pronounced flexibility we support our customers event of planned or unplanned processes. Take advantage of our production capabilities, and our experience to your advantage. - Mechanical processing such as milling, turning, drilling, grooving - spaces CNC or conventional - Assembly of components including pneumatic, electrical or construction Demand Unexpected wear, collision, unplanned events quick action - Manufacture of individual parts according to data, samples or consultation - Modules - eg partial assembly if desired with all purchased parts - Subcontracting including procurement of materials and treatment

Founded

1996

Employees

10 - 20

Certifications

Frankenberg

Germany - 35066

Erhard HIPPE KG specializes in the production and processing of engineering plastics, from standard to high-tech material. As one of the world's leading companies in the plastics sector, we have an enormous range of special grade thermosets.

Founded

1935

Employees

100 - 200

Certifications

Hildesheim

Germany - 31134

'The Kost company is 2004 was founded and a family-run company. Customer loyalty and quick communication and implementation of your plans set us apart. Get to know us and work with us. We look forward to you.

Founded

2004

Employees

< 5

Certifications

Schmallenberg

Germany - 57392

3 DDD is a medium-sized development and production company that is active in the business areas of development and construction of mechatronic devices and additive manufacturing with a focus on rapid prototyping and rapid tooling. We have already been able to greatly reduce development times and development costs in the development and construction of mechatronic devices and systems. Even functional components of the 3 DDD are used in various products. 3 DDD was founded in 2015 and has made a name for itself with the development and manufacture of mechatronic devices and the optimization of the production of components using additive manufacturing methods.

Founded

Employees

< 5

Certifications

Kelkheim

Germany - 65779

Matthies Druckguss has been working with you as a partner since 1955. During this time, we have been able to gain significant experience and acquire important knowledge in the field of die casting, which makes up our know-how. Today, we are not only the “die-cast supplier” for our customers, but also take on a wide range of tasks for them (system supplier), with the aim of a cost-effective product. By selecting nine different alloys from the areas of aluminum, brass and zinc, intensive advice during the initial planning processes, precision-precise design and subsequent custom-made production of series parts, we guarantee that we will meet your requirements. Together with you, we develop the optimal casting part, plan the optimal layout of the casting system and finally manufacture the mold in our in-house tool shop. We then sample the first tool-falling castings under series conditions and present the samples to you. If everything is in order, then we start our fully automated series production in our die foundry. In further steps, the cast raw parts are deburred and mechanically processed using precise CNC processing centers. Finally, the finished parts are prepared for shipping. With our partner shipping company, we ultimately ensure fast and problem-free delivery of the goods. We see ourselves as a system supplier. Because this is how we make things as easy as possible for our customers and their ordering as pleasant as possible. We take on all tasks from A for “delivery of raw materials” to Z for “delivery of finished castings.” And since everything comes from an experienced source, customers can rely on the fact that consistently high quality is guaranteed and that the results will be delivered to the desired location in exact quantities and on time. Thanks to a local partner shipping company, a rarity among die casting service providers, delivery is neither delayed nor do customers have to contact third parties. It's obvious that our logistics department not only takes care of the delivery itself, but also the required packaging. Relevant benefits that are decisively reflected in satisfaction time and time again. Unbeatable when it comes to service, too: We can react flexibly even if changes are requested at short notice. And thus deliver a full range of die-casting services with a well-thought-out system. A functioning production chain that ranges from the initial die-cast idea to the sample piece to the finished series. - Various aluminum, zinc and brass alloys - Certified according to DIN EN ISO 9001:2015 - custom-made castings - short delivery times - perfect quality - Use of proven and innovative technologies! These are just a few of the features that make for exciting precision work. Personal customer advice and support is just as important to us. We support our customers right from the start so that the result really meets their requirements — a matter of course for us as a family business.

Founded

1955

Employees

20 - 50

Certifications

RENDSBURG

Germany - 24768

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Your specialist for mechanical metal processing in Friedberg (Bavaria) We are a highly specialized company for mechanical metal processing and have been offering timely, order-based single-part and series production for mechanical and plant engineering for over 20 years. Our range of services includes the production of welded structures, the production of turned parts and milled parts, ready-to-assemble assemblies including development and CAD design.

Founded

2001

Employees

20 - 50

Certifications

Friedberg

Germany - 86316

Founded

Employees

< 5

Certifications

Dortmund

Germany - 44319

We offer capacities in the contract manufacturing of: We are Since 1986, suppliers of high quality drilling and milling parts with modern machinery. Our strength Präzisionsbohr and milled parts in small and medium Lot sizes up to 100,000 pieces, fixture and custom. Have we piqued your interest? Then we will be happy to give you more details to be allowed and you interesting offers for our contract manufacturing submit. PRÄZISA clamping technology * RTV Clamping System * RTV base clamping body * RTV Accessories * RTV special clamping solutions * Blowguns holder * Contract Manufacturing

Founded

Employees

10 - 20

Certifications

Ottensoos

Germany - 91242

The company Helmut Eltner tooling GmbH is a family business. They emerged from the company Koser & Eltner which was founded in 1966 by Hans Koser and Helmut Eltner in Main Valley / Wachenbuchen. After the death of a shareholder, the company was taken over by Helmut Eltner 1982. It soon became apparent that the old premises did not allow for necessary investments more. Therefore, a 3500m ² plot of land was purchased in 1989 in Kahl / Main and built a 800m ² building, which was purchased in 1990. The machinery has been since that time continuously expanded, and modernized in order to respond flexibly to customer requests. In 1996, Dipl-Ing. Ralf Eltner ordered the second managing director, the company is run by him alone since 2001. Manufacturing Technology Flach-/Profilschleifen Rail profile grinding Wire EDM Die sinking Hole EDM from Ø0, 6mm Gauge Jig Grinding Milling, drilling HSC milling Turn CAD / CAM

Founded

1985

Employees

5 - 10

Certifications

Kahl / Main

Germany - 63796

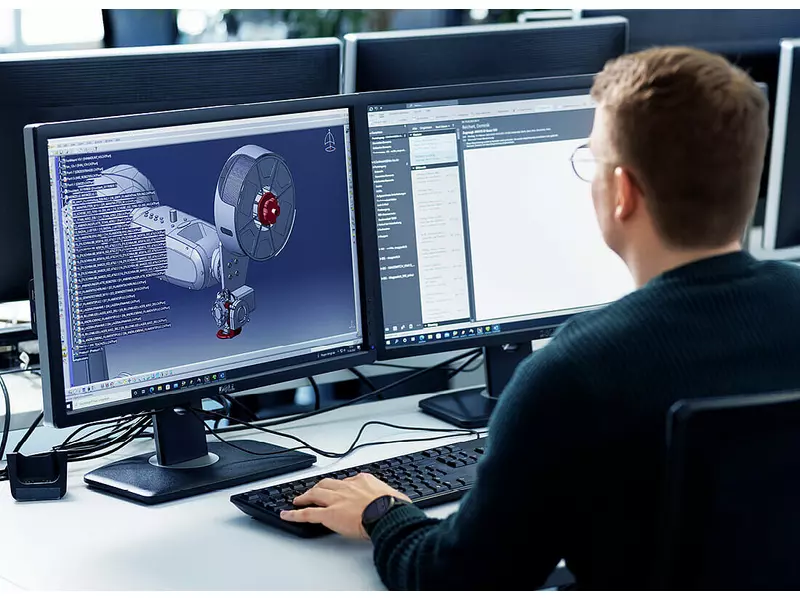

As THE automation architect, we support your automation project from planning to implementation. Especially at the beginning, it is important to hedge the investment risk through a feasibility study. We optimize your production through targeted automation solutions or assist you with new systems. We will take over or assist you with plant planning, robot simulation and equipment design. If you have your own tool shop, you will receive the finished drawings and layouts for implementation or we will also support you here, including the turnkey system.

Founded

Employees

50 - 100

Certifications

Karlsruhe

Germany - 76185

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge