Hard turning: get complete market transparency

Discover specialized suppliers for hard turning on Techpilot. Our platform connects buyers with suppliers who use advanced turning technologies to machine hard materials with high precision. Use the e-sourcing process to find the best suppliers.

2024 suppliers for Hard turning

Started the Brecht GmbH in 1990. Since those early days is carried out in accordance with the motto "Macha M'r". Thus, the focus of production on complex and high-precision CNC turning parts, CNC machined parts and CNC waterjet cutting parts is with a 90 ° cut, thanks to our automatic swivel head. Since November 2014, we also offer the topic 3D printing or additive manufacturing. This makes us the complexity of a workpiece hardly limits. With additive manufacturing, we also cooperate with competent partners, so that we can offer a wide variety of types of additive manufacturing. In addition, we can rework the parts with our CNC machines to the desired precision and surface quality. When Brecht GmbH has joy of solving problems together with the customer. Together new ways be found. From this, a further customer base has grown. It comes from the following areas: mechanical engineering Automation technology Precision Engineering Medical laboratory technology Orthopaedic technology measurement Analytik chemistry Aerospace Engineering Automotive Industry Motorsport Electrical computer firms Our focus is in plastics technology in the processing of plastics and high-performance plastics and nonferrous metals.The processing of special materials is standard daily. We grow with our tasks and so over the years is "Can" and customers' confidence grew harmoniously. For these reasons, we look forward to your challenge! The machinery was the need constantly adjusted and is now technologically up to date. In Brecht complex contracts are not complicated but precise. Quality is one of our specialty, which is confirmed by the regular and successful certification according to the ISO 9001 standard.

Founded

1990

Employees

10 - 20

Certifications

Wannweil

Germany - 72827

Orfanidis Anastasios, having ORMIT as its distinctive title, from the early years to today’s rapidly changing environment, maintains a history of continuous effort, challenges, and evolving technical experience. The company started operating in 1991. Over the years, it has been transferred to privately-owned facilities in the Drimos, Thessaloniki. Since then, the company has begun its investments in the CNC machines sector, starting the course towards a higher level of technical knowledge and experience, as well as a higher degree of flexibility.

Founded

1991

Employees

5 - 10

Certifications

langadas

Greece - 57200

We produce turned and milled parts according to the highest quality requirements. The processing possibilities, surface treatments and a modern warehouse combined with fast and efficient logistics management make us the ideal partner for your projects. Our components can be used in gaskets, co-molded with other materials, used in the assembly of other components such as gears, valves, plastic manifolds, etc. We are able to supply turned parts with complex geometries and elaborate milling jobs (e.g. asymmetrical geometries, cross holes and threads) up to a diameter of 60 mm Long turned parts with diameters from 5 to 22 mm and a turning length of up to 200 mm (milling work using the y-axis) CNC turned parts with diameters from 5 to 65 mm (e.g. with face milling for keys, eccentric operations and trapezoidal threads) Circular turned parts (e.g. with milling and threading) THE MATERIALS WE ARE ABLE TO WORK: Stainless steel eg. 1.4301, 1.4305, 1.4401, 1.4571 Automatic steels eg. 11SMn30 + C (1.0715), 11SMnPb30 + C (1.0718) Steels eg. St 37-2, C15 Brass / tin bronze eg. CuZn, CuSnZnPb, CuZn39Pb3 (MS58) Aluminum eg. AlMgSi, AlCuMgPb

Founded

Employees

5 - 10

Certifications

Alpignano

Italy - 10091

Our family business was founded in 2017. We are a two man company consisting of Tim and Ralf Eschenbacher. Our company stands for excellent quality, good cooperation, high reliability, timely compliance with production deadlines, as well as quick and flexible action on short and urgent deadlines. Our next goal in the company is certification with ISO 9001:2015 quality management system. We offer you the following services: - CNC milling of individual pieces, prototypes, small and large series -conventional turning of individual pieces, prototypes and small series -Drilling -welding work -Assembly of components -dimensional coordination of components with each other

Founded

2017

Employees

< 5

Certifications

Satteldorf

Germany - 74589

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are committed to improve and strengthen your products. We place at your disposal and to the service of your projects the whole of our company: design, technology and quality. Let us be a part of your team. Our company Factor is a company whose activity is the in-line machining of special parts using CNC spindle lathes (bar cutting) and the cold stamping of screws. We have had both national and international market presence for more than thirty years in sectors which require a technological product with a high added value. Our corporate strategy is based on 4 pillars: Continuous investment which guarantees the continuity of our project. Innovation as the culture of continued improvement. Industry for our passion of creating components which materialize our customers’ ideas. Internationalization as vocation for the geographical expansion of our management model. Among the advantages for our customers, we highlight the following: Cutting-edge equipment which guarantees a high reliability, repeatability and competitive finishes and prices. Know-how and experience gained during our wide track record make us posses a high level of product knowledge and processes. Highly qualified staff and focused on customer satisfaction. More than 50% of our staff are university graduates and have specific training in the machining sector.

Founded

1982

Employees

50 - 100

Certifications

Puzol

Spain - 46530

MEC4I - Mechanical Cluster for Innovation is a group formed by 5 companies operating in the field of precision machining. Actually, the group have 40 NC centers (turning, milling EDM); of these, 12 are 5-axis. The group employs more than 100 people. The manufactured parts are used in many different applications, including aerospace, defense, oil and gas, packaging, biomedical, motorsport. The business proposal is manufacturing of mechanical parts on drawing, both as individual pieces or assembled groups. There is also the capacity to operate as prime contractor for the management of complex systems.

Founded

Employees

100 - 200

Certifications

Livorno

Italy - 57128

Production of rotationally symmetrical rotational parts 12-65 mm in diameter from all machinable metals. Our specialty is the machining of stainless steel materials (from 1.4021 to 1.4571). Sample parts can be found at: www.rommel-praezisionsdrehteile.de In modern CNC lathes with Alligator - Spindle or counter-rotation symmetric turned parts from a variety of metals are produced. These high demanding precision turned parts are manufactured according to customer requirements as a single series parts or assembled into smaller modules. Typical batch sizes of 100 - 30,000 pieces. Processing options - CNC turning - Polygonal - Eccentric rotating - Milling - Drilling, reaming - Threaded drill, chasing - Knurling Heat-treatment - Hardening, pay etc (see services) Suitable materials are - VA of 14021 to 1.4571 - Machines Bright Steel - Quenched and tempered steel - Stainless Steel - Brass - Aluminium - Special materials such as titanium Touch up - Install - Vibratory Finishing - Deburring Surface treatment - Galvanize - Nickel - Chrome plating - Brown - Phoshatieren etc (see services) - Vibratory Finishing - Deburring Are conditionally suitable - Refractory materials - Heat-resistant materials

Founded

1928

Employees

10 - 20

Certifications

Gemmrigheim

Germany - 74376

For over 50 years, this name is a guarantee for high-quality precision turned parts. The high quality standard of our products is the result of consistently pursued quality policy in all areas of our house. From the delivery of the raw material to delivery of the finished product provide the latest technology and the know-how of our qualified employees, ensuring optimum production conditions and excellent results. Our high quality does not apply only to our products, but also for dealing with our customers. A competent and friendly team who grants you any assistance and leads your orders to your exact requirements and deadlines from. The custom alignment is our top priority. We want to make it clear with our comprehensive service. Not alone the quality of the products makes a supplier for a suitable partner but also the flexibility, speed and service. From the first moment we support with high level of expertise your order. Maximum flexibility, we are also proving meet your individual requirements. This starts with the date of delivery, we align your expectations. You determine how and in what units your future products are packaged and tell us the shipping method. Our range of services includes: CNC machining Turn Mill Grind Assembly production Electrolytic labels

Founded

1955

Employees

20 - 50

Certifications

St. Georgen

Germany - 78112

We offer technically sophisticated solutions and services for all kinds of engineering. We offer services in welded parts, assemblies and manufacture turning parts made of different materials. We work with your delivery terms. In the company DANSTR store s.r.o., we are experienced in the field of: - cooperation, - renovation of worn-out tools, - technological analysis of production processes, - design and production of special tools, - comprehensive expert advice, - distribution - and the sale of tools. Our goal is to build long-term relationships with our customers and therefore our activities are based on flexible and customer-oriented approach. Through the introduction and investment in new technologies, we are working hard to increase the quality and reliability of our products and services, to the satisfaction of our customers. Please contact us for more information.

Founded

2011

Employees

< 5

Certifications

Smirice

Czech Republic - 50303

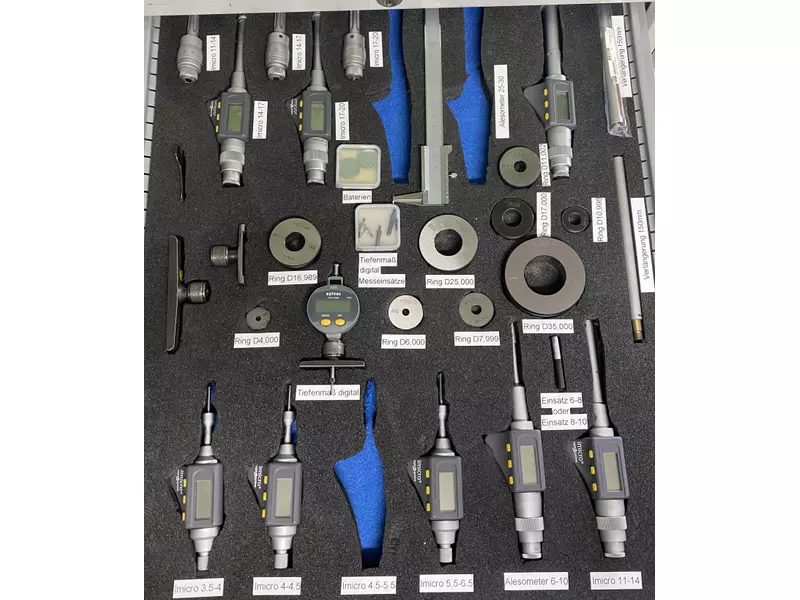

KFG Vorrichtungs-Technologie GmbH is your competent partner for device technology in Austria and beyond We are a service provider and partner for the industry, whereby high-quality products, quality and customer satisfaction come first. Aspects of accuracy, flexibility and technical know-how are combined to guarantee the success of the customer in the market. We are your partner for Machining devices Measuring devices Test gauges Prototypes Series & single part production Constructions Measurement service

Founded

2002

Employees

10 - 20

Certifications

Neuzeug

Austria - 4523

The PSFU Wernigerode GmbH is a family business with 30 years experience in high-precision machining. There are not many companies in Europe that can offer such a comprehensive solutions for the flat, circular and non-circular profile grinding. In addition to our high-precision grinding technology, we offer an extraordinary know how in the fields of 5-achsis-milling and precision turning. We are partner of the automotive and mechanical engineering industries. Our customers include Europe's most important automotive, printing machinery, medical and machine tool manufacturers. Universal CNC machining centers allow the production of various precision parts and guarantee flexibility and capacity for prototype, in the single-part and series production. A separate tool and fixture completes the service to our customers.

Founded

1992

Employees

100 - 200

Certifications

Wernigerode

Germany - 38855

We are an experienced company that deals with CNC machining. We employ professionals and create with passion.

Founded

2019

Employees

20 - 50

Certifications

Strojec

Poland - 46-320

We specialize in the design and manufacture of hydraulic cylinders, their individual components and fasteners (bolts and safety devices). We also offer services in the areas of machining, inert gas welding, special hydraulics, new and overhaul hydraulics as well as in pit casings.

Founded

1990

Employees

10 - 20

Certifications

Tarnowskie Góry

Poland - 42-680

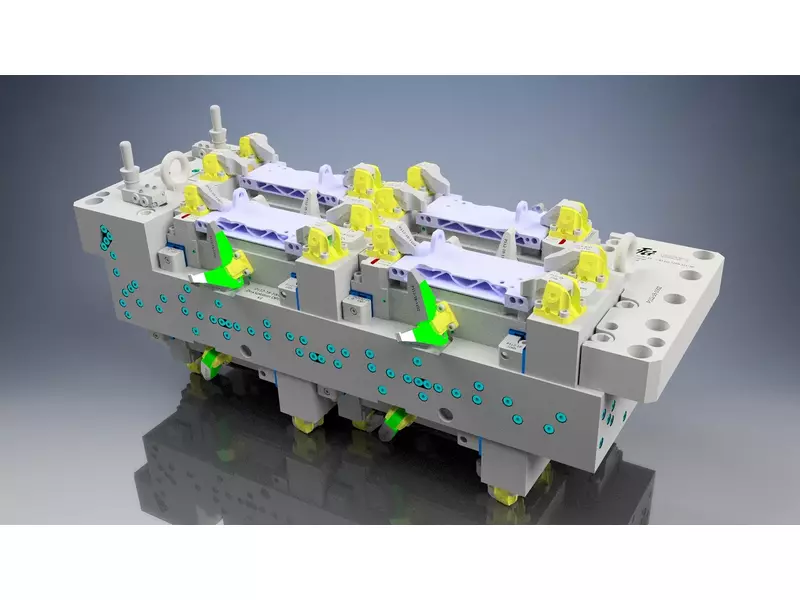

As a certified (9001: 2015) family business, we specialize in the manufacture of CNC precision parts. We manufacture small and medium batch sizes on over 40 CNC machines. Manufacturing facilities CNC turning CNC milling Cylindrical grinding between tips Centreless grinding Deep hole drilling Thread rolling Honing Laser marking Magnetic crack testing 3D coordinate measuring machines Form tester Contour measuring device Pressure test bench Waves laser measuring device

Founded

1924

Employees

20 - 50

Certifications

Augsburg

Germany - 86165

Our company deals with production of mechanical parts made from milling and welding turning. We have n ° 11 numerical control machines to draw all the mechanical parts required by our customers. From the acquisition of the order to the shipment of the goods is constantly monitored in order to ward off even the slightest error. Quality is a key part of our customers' trust

Founded

2001

Employees

10 - 20

Certifications

Treviso

Italy - 31030

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

MILLTECH is an Italian company based in Bologna specialised in the production of high-precision mechanical and micromechanical Milling and Turning components according to customer's drawings: Milled parts can be 1x1mm to 10m large, and Turned parts ø3-300mm. We work all kinds of materials (aluminum, brass, bronze, copper, steel and stainless steel, titanium, plastics) and are very competitive in medium-big production batches from 30-50 pieces up to 500-5000 pieces. We already are trusted supplier of many companies in Italy and Europe and we look forward to counting you as one of our customers.

Founded

1997

Employees

20 - 50

Certifications

Zola Predosa (BO)

Italy - 40069

welcome when Otto Weisleitner GmbH We are your specialist for mechanical engineering & manufacturing technology and are able to offer our services for: * Elaboration of concepts, 3D designs, calculations and dimensioning, CE marking * Production with turning, milling, grinding, water jet cutting, with focus - series production of rotary milling parts on state of the art combined lathes, milling centers, as well as the machining of large and long shafts up to max. Dm 500 x 3000 mm. * Pressing and welding * Assembly of modules to kopmplexen machinery * Sensors, pneumatics, hydraulics, drive technology * Maintenance, Servicierungen, repairs, alterations * Survey and reconstruction of machine parts * Advertising technology, product design, inlay work

Founded

1978

Employees

5 - 10

Certifications

Wiesing

Austria - 6210

RK-tec Klostermeier Maschinenbau e. K. stands for a company with highly qualified and motivated employees, which know-how solutions for new and existing systems in the area Machine / plant construction and conveyor technology supplies.

Founded

2006

Employees

20 - 50

Certifications

Aiterhofen

Germany - 94330

COMERCALO 'srl Brindisi Italy Precision mechanical constructions. Turning, milling and grinding. We manufacture tools based on the customer's design and models (bonding, contouring and drilling tools, etc.) We produce spare parts with subcontracted material or with material supplied by us. We perform precision mechanical machining (milling, turning, grinding) The maximum dimensions of the pieces that we can manage are mm. 1600x500x500. We always have raw materials in stock such as 7475,7075,7050,2024, 17-4-PH, carbon steel etc. We can perform either mechanical processing and dimensional control only or we can supply complete parts of SURFACE TREATMENTS. As for the surface processes in Italy, our partners are Galvair, Metalsud and Tecnotrattamenti but we can also have the support of Galvatec in Spain and Mecacrome in France, with processes qualified by Boeing, Airbus, Bombardier etc. We build special custom equipment. For small series we are very fast in production. Our transport partner in Italy is GLS EXECUTIVE and in Europe it is DHL.

Founded

1986

Employees

20 - 50

Certifications

Brindisi

Italy - 72100

Company founder Hans Georg Hillreiner was always convinced of the idea of self-employment. In 1987 he successfully passed his master's examination. With this qualification and the subsequent foundation In the original mechanical workshop, he begins production on his first machine. A small series for MAN and cruisers as well as devices for BMW are manufactured on it. In 1991, the move into the new company building follows, as another machine is needed due to the great demand. Due to the high quality of the parts produced and the associated increase in orders, a support worker was hired in 1995 and the existing production building was enlarged. In 1998 a new production building is built. This is equipped with new machines and more employees are hired. In 2000, customer demands and orders are increasing rapidly, requiring the production of larger quantities of a wide variety of parts.As a result, an administration and office building is built in 2001 and HGH moves into it. In 2017, HGH was renamed a GmbH and handed over to the daughter Barbara Hillreiner. Our management system was already certified according to ISO 9001:2008 in 2011. As part of the re-certification, we were audited and certified according to the new ISO 9001:2015 in autumn 2019. Due to constant testing of the effectiveness of quality-related activities, the organization and methods of quality management in our company are constantly being adapted to the latest findings and requirements.

Founded

1987

Employees

5 - 10

Certifications

Markt Indersdorf

Germany - 85229

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge