Injection moulding: get complete market transparency

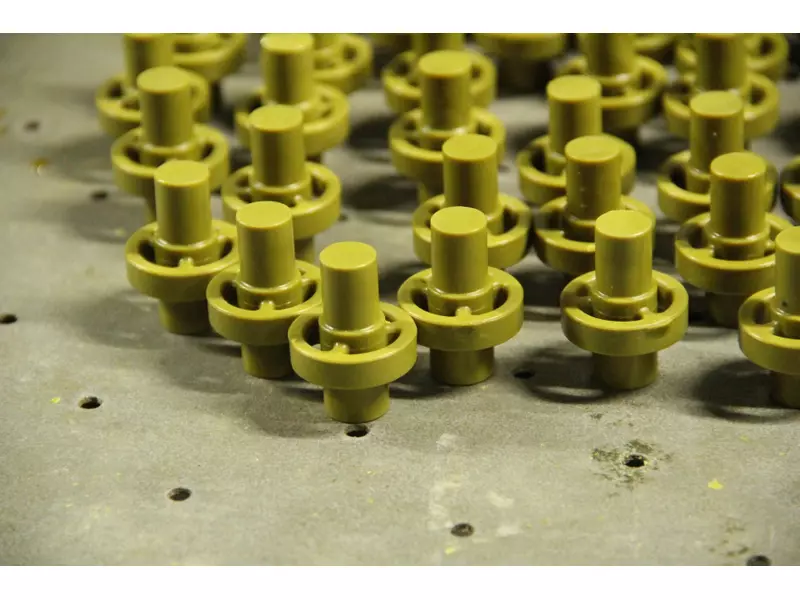

Find specialized suppliers for injection molding on Techpilot. Our platform offers access to suppliers who use this forming technique to manufacture precise plastic parts. Benefit from comprehensive market transparency and optimize your supplier selection.

903 suppliers for Injection moulding

In our, in 2000 newly opened modern requirements of production and rehabilitation justice to the workplace, we produce under the expert guidance of qualified engineers, foremen and skilled workers in two buildings with more than 200 disabled and non-disabled employees for the industry in the areas of: - Industrial and electrical installation - Metal processing - Plastic manufacturing and processing - Packaging and packaging Our services are in accordance with § 55 SchwbG creditable against the countervailing charge with 50% of net job performance.

Founded

1992

Employees

200 - 500

Certifications

Meiningen

Germany - 98617

POLIFORM started in 1979 as a private, family operated mould-making workshop. In 1990 it evolved into a private enterprise assuming the new name of POLIFORM d.o.o. (Limited Liability Company). - Located in Valjevo, company's private property consists of 1500 m² of production and administrative facilities.It includes a mechanical metal cutting workshop and a thermoplastics processing workshop. - Our basic activity is the production of moulds for the injection of plastic mass under pressure. We produce moulds according to the sample, our own documents or the buyer's documents. - We have produced over 400 moulds so far. Maximum dimensions of the mould which we can produce are 1000X800x800 mm. According to our technological possibilities, we produce spare parts and assemblies based on the buyer's documents and the parts for special purposes We own machines for the injection of plastic mass with the capacity from 60 to 1600 gr. - We use the tools of our own construction and workmanship. The annual capacity of the plant for the processing of plastic mass is about 120.000 kg.

Founded

1972/1991

Employees

10 - 20

Certifications

Valjevo

Serbia - 14000

The life coaching Chemnitz eV was founded on 23.06.1990. It currently has 240 members and supervised in the various facilities about 450 people with intellectual disabilities. The workshops are facilities for the participation of disabled persons in working life. They integrate people who do not, can not, or not yet again be working in the open labor market because of the nature and severity of the disability. In the workshops, a training area is available. Our range of services: Electric field: Production and assembly of electronic components, assembly of components and devices, disassembly of assemblies and electronic components, inspection and testing activities to customer and preparation of components Equip the production of individual components of different modules, complex assembly (brake and fan modules), quality control, packaging and heatsink with components: Installation Packaging and assembly: Compilation of clothing bags and packaging, production of cardboard and overpacks and control Preparation of components: bending (grid, expand or-Narrow), beads (simple or twisted), Shortening, apply fabric hose, apply heat shrink tubing and shrink, Ausgurten of axial or radial taped components, Manufacture of wire bridges Metal Machining: Machining (turning, milling, drilling, reaming, tapping, grinding and deburring), welding (spot welding), Abkantarbeiten and bending work Post and promotional products Laundry and linen finish Sewing Bookbinding In construction injection area (multi-component injection molding and insert molding) Clamping force range 150-180 t. Laser cutting and laser engraving (no metals)

Founded

1990

Employees

200 - 500

Certifications

Chemnitz

Germany - 09111

HEAVY - It's EASY for us! Pro-Moulding has over 30 years of experience in the field of plastic injection molding and has been characterized by precision, quality awareness and speed from the very beginning. Our high quality infrastructure guarantees a full service from mold and product development to serial production and numerous services. Through the motto "hard comes easy to us " the company has developed as a relevant partner mainly in Austria, Germany and Hungary. With an ultra-modern machine park in the high tonnage range, even the largest components can be easily implemented. We supply well-known equipment and component manufacturers in the outdoor, industrial, office furniture, medical technology and automotive sectors. Pro-Moulding employs about 100 people and is a company with a very solid financial background. With our modern machinery we are specialized in the production of large volume plastic parts. Our employees and the consistent implementation of the motto 'hard comes easy to us' are the success components for high customer satisfaction and growth. We process common engineering plastics such as ABS, POM, PA6.6, PPS, PBT, PP, PMMA and many other materials on 10 modern robot-controlled ENGEL machines with clamping forces from 88 kN to 2300 kN and shot weights bigger than 10.000 g. Our unrestricted goal as a company (team) is to be an A-supplier for each of our customers and thus a partner. To meet this claim, the continuous improvement of our processes (CIP) as well as the regular auditing of our quality management according to DIN EN ISO 9001:2015 is a matter of course for us. Our quality claim starts with the preparation, is accompanied by regular and random checks, internal and external audits and is ultimately supported by the high motivation of our employees. Certified according to EN ISO 9001:2015 and EN ISO 14001:2015 A direct contact person, supported by digital processing and confidentiality agreements, is part of a successful cooperation.

Founded

1992

Employees

50 - 100

Certifications

Nagykanizsa

Hungary - 8800

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Located in Viganò (Lecco), 40 Km from Milan (Italy)over an area of 5,600 square meters , Zeta Stampi srl has been designing, building moulds and injection-moulding plastic material for third parties for over twenty years. We also manage post-molding processes such as painting, metallization, chrome plating, pad printing and screen printing. We have an updated workshop with numerical control machines, CAD / CAM softwars,No 14 injection molding machines from 60 to 900 tons, measuring room and ISO 9001-2015 certification. Our main fields include automotive, electronics, appliances,household appliances, garden machines, furnishings, advertising technology, household items; layette and the cosmetic industry. In any case, we have skills and adequate structures to manufacture products for other sectors. Get in touch with us so we can help you with your projects, in terms of costs, quality and delivery times

Founded

1996

Employees

20 - 50

Certifications

VIGANO

Italy - 23897

Aria Manufacturing Limited

Aria was founded on a simple principle of providing the customers with one-stop solution of design, development and production for both plastic and metal components and its support tooling. And we are set to compete in anything the industry has to offer in terms of quality, price and services. Aria’s high-tech manufacturing and production facilities include CNC Turning, Milling, Injection Molding, Die casting, Stamping as well as a range of finishing techniques. We welcome your queries!

Founded

2010

Employees

200 - 500

Certifications

COVENTRY

United Kingdom - CV2 4AQ

Welcome to Brandauer – Your Partner for Precision in Plastic Processing As a family-owned business with four generations of experience, we have been active in the plastics industry for decades. Our passion for innovation and quality drives us to continually set new standards. By combining traditional craftsmanship with cutting-edge technology, we offer tailor-made solutions for technical plastic components that meet your exact needs. Why Choose Brandauer? Highest Precision: With 70 dedicated employees and 47 state-of-the-art injection molding machines, we set new standards in quality and precision. Broad Range of Expertise: Our core competency lies in injection molding of technical plastic parts, the production of hybrid components, and overmolding of inserts and bushings. Innovative Development: We don’t just see ourselves as manufacturers, but as partners. Together with you, we develop new solutions, test materials, and bring our extensive know-how into every step of the development process. Custom Manufacturing: In addition to injection molding, we also offer tool and fixture design, as well as precise assembly and complete assembly of components. Additional Technologies: With our mirror welding machine, we can create highly precise welding connections, offering even greater quality and versatility. We focus on quality, innovation, and collaborative partnerships!

Founded

1905

Employees

50 - 100

Certifications

Mieders

Austria - 6142

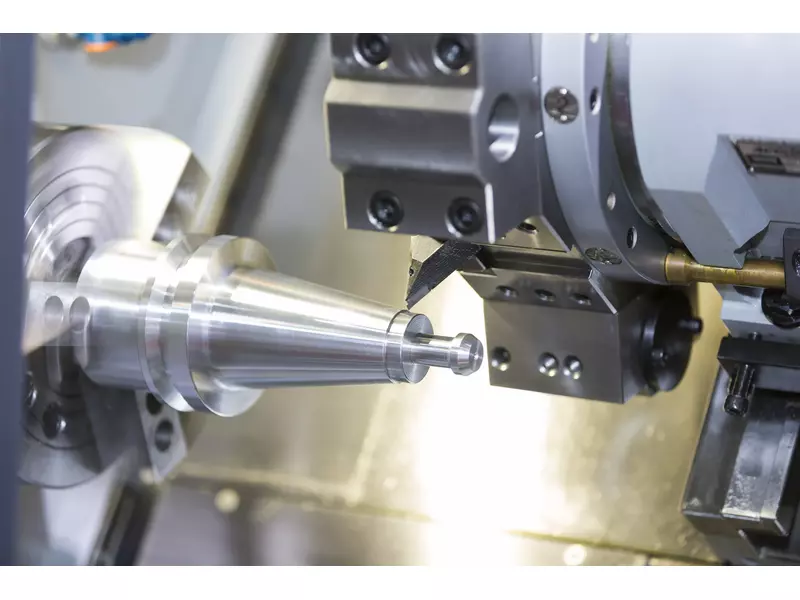

Varied applications, supreme reliability: That’s the world of CVT-Capellmann products Our products have a highly reliability and are used in the automotive section, power tools and home appliance. The application of our parts, reaches from electrical and manual seat adjustment, over engines, gearboxes and pumps to actuators and the entire engine management. The industrial specialization of CVT pays off: State-of-the-art equipment, above-average performance, experienced employees - specialization is definitely worthwhile. Besides our geared parts and worms, we also produce subassemblies up to high volume orders. Since 2000 we also produce many kinds of turned parts. The long turned parts are complete produced in our plant PTS-precision GmbH in Schwerin. Geared parts Cogs, Pinions, Worm Gears, Worms, Subassemblies, Turned parts, CNC longitudinally turned parts, Chucked turned parts, Turned parts from rod, All machinable materials

Founded

1979

Employees

100 - 200

Certifications

Gosheim

Germany - 78559

TUGSAN

TUGSAN is established in 2005. We are manufacture of plastic injection mould, rubber injection mould, control fixture and special design of automation machine. To produce tools, special design of automation machine, plastic part production, fixture and the other technics for our customers. To become a leading company- firm in Turkey through continual improvements, and customer satisfaction by maintaining a permanent staff who is qualified with principles of nature health and environment productivity and quality. To be leader in price and quality; to save our avaliable market and to achieve our targets in market and capacity To ensure the productivity for all activities.To make preventation of improvidence To satisfy our customers To improve new products by using R&D studies and high product tecnologies.

Founded

2011

Employees

10 - 20

Certifications

16120

Turkey - BURSA

Manufacturer of connectors and contacts with our own production and our own tool shop

Founded

1942

Employees

> 1000

Certifications

Mühldorf

Germany - 84453

Welcome to CAD-Plast GmbH. We combine the latest standards with innovation and efficiency and combine the properties mentioned with years of experience and dynamism. In October 1999 a vision turned into a company. The trust in our competencies and the will to realize the ideas of our customers has paved this way for us. We face all challenges that the future demands with commitment and know-how, focusing on constant dynamism and progress for the benefit of our customers ... We manufacture with our team for our customers in the area Automotive Special mechanical engineering Medical technology Sporting goods in the fields of mechanical processing and mold construction as well as in plastics processing.

Founded

1999

Employees

20 - 50

Certifications

Aichach

Germany - 86551

TERNPLAS was founded by Ergün Toprak, a native of Baden-Württemberg in Germany, and with his German industrial expertise in the automotive industry, he runs the production site in Ankara / Turkey with enthusiasm. TERNPLAS supports its customers with technical and manufacturing innovations. With unparalleled technological expertise in machining, mold construction and plastic injection molding, it is a proven supplier of high-quality and complex parts as well as development and service partnerships for customers in the automotive, medical, defense and general sectors. As a development and service partner, Ternplas accompanies its customers in the selection of design and materials and, through close, professional exchange, achieves the best solutions and cost-effectiveness. Ternplas produces worldwide for its customers with the most modern machines and systems with efficient, high quality and robust processes in series production. We make our important contribution to the continued success of our customers. Our customers appreciate and benefit from our lucrative services from development, series production to logistics with advantageous production costs in Turkey. "The key to our success is the success of our customers"

Founded

2016

Employees

5 - 10

Certifications

Öhringen / Ankara

Turkey - 07941 / 06980

Manufacture of plastics and deep-drawn parts according to customer drawings and the associated tools We are happy to take care of: development / design, printing, painting, chrome plating, plating, assembly, component manufacturing, logistics

Founded

1975

Employees

20 - 50

Certifications

Haigerloch

Germany - 72401

Edr Fittings boasts over 20 years of experience. EDR Fittings is the European leader in the outsourced production of micro-castings and machining. Our widespread presence on the Asian territory allows us to offer an optimal service for every type of requirement on castings, machining, assemblies, pneumatics and stainless steel fittings. Specifically, the technologies we use are: - Cast - Lost wax castings - Cast iron castings - Lost Foam - Die casting - Investment Casting - Extrusions - Hot forging - Plastic molding injection Our company guarantees the control and management of the orders by following step by step all the phases agreed with the client, also offering a customized 2D / 3D design service and stress analysis. The strength is the aggregation with productive partners of the Asian market, inventors for many years of this casting technique, with which we can guarantee quality that will surely meet your needs and at prices that in most cases make it possible to amortize the mold costs already from the first production lots. All our "partners" have been subjected to thorough audits and adhere strictly to our Quality agreement as required by the ISO 9001 DNV and EPD (Environmental Product Declaration) certification procedures; furthermore the materials produced are tested and verified by our internal metrological laboratory which includes CMM, durometer, roughness tester and various bore gauges. Our goal is to always be present both with our customers and suppliers, giving immediate answers and an indispensable direct contact to achieve the result in a short time.

Founded

2002

Employees

5 - 10

Certifications

Genova

Italy - 16135

We have 40- years experience of investing in modern equipment and training of our associates to ensure we have the foundations to consistently produce quality products. We have a wide range of experience in producing quality products mainly consisting of thermoplastic materials which are used as components for electroindustry, electronics and home appliances. Our production is equipped with the latest technology injection moulding machines and is appropriate for small and large-scale production. Most of our products are made of engineering plastics. We are currently working with 18 injection molding machines (Engel, Krauss-Maffei) with up to 2200 kN clamping force.

Founded

1977

Employees

10 - 20

Certifications

Kranj

Slovenia - 4000

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

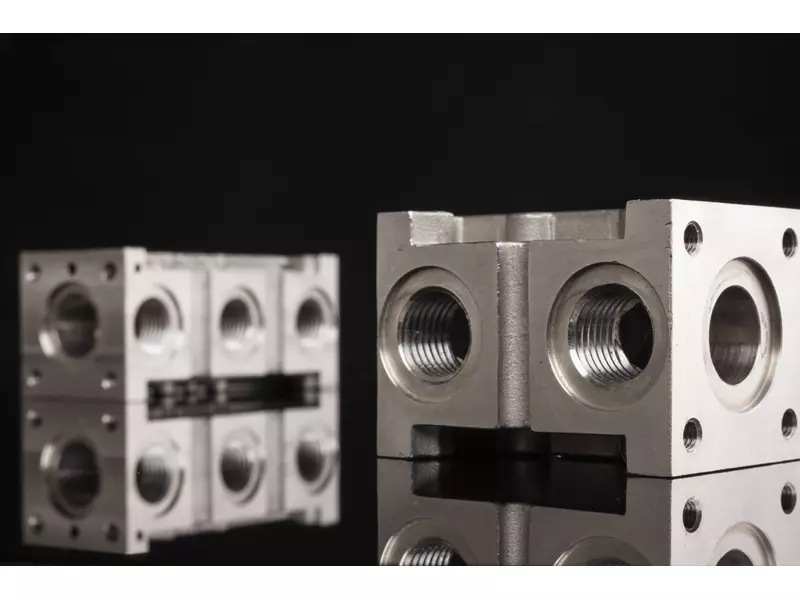

Highest quality, efficiency and reliability - our customers expect when you leave their components finished with us. Thanks to our experience, a strong quality consciousness and modern production technologies, we can fulfill these requirements to the satisfaction of our customers. As a medium-sized company, we supply parts since 2006 for well-known manufacturers from the machine and tool manufacturing and the consumer goods industry. So in our plastic and assembly area, we mainly produce plug inserts and plastic components for the electrical industry, while we finished in the metal-working individual, self-, small-and series parts according to our customers. With our own design department, we are able to bring our experience in the planning phase. Often we are able to present potential for a more efficient implementation of a project open, such as in the development of user-friendly components in the area of feeding and assembly automation. What part of our range of services is always of interest to you - the production of your components is in the best of hands! Metal components for the machine and tool - thoughtful and precise. Machining In modern 3 - to 5-axis milling machines we chipping any kind of metals according to your requirements and specifications. Whether items for special machine or Schmiede-/Gussteile for mass production - we are able to produce your components precisely and economically. Jigs For your parts to be machined design and manufacture mechanical and hydraulic tensioners-cost production for your machines. Our mechanical clamping devices are characterized by ergonomic handling and easily operated. They are particularly suitable for medium-sized series and allow the situation safe positioning of the workpieces. For the machining parts manufacturing the hydraulic tensioner is used. Our devices give use free process with high reliability. Special machine Tailored to your needs! As cost-effective supplement for the manual production, we develop components and special machines for the automated processing of assembly and inserts - tailored to your requirements. Components with brains Plastic standard components for the electrical industry - economical and reliable. In the manufacture of plug bridges we focus primarily on the three most popular types on the market: the euro bridge (2.5 A), the Schukobrücke (16 A) and the contours bridge (10-16 A). In addition, we manufacture equipment boxes and other components for the electrical installation. Our plug inserts are characterized by the use of material-saving components that we have developed specially in view of the steadily rising commodity prices.Our hollow pins Black Pint ® or our cold formed pins provide, for example, a material savings of up to 55%! So we can offer you a high quality, functional, standards-compliant product at an absolutely competitive price. Available information on the designs can be found in this brochure. If you do not find a suitable for your application design, please contact us - we are able to realize even special in flexible quantities. Plug inserts with hollow pins: Contours bridges, Schukobrücken Plug inserts with solid pins: Euro bridges, bridges contours, Schukobrücken, device boxes, special bridges

Founded

2006

Employees

5 - 10

Certifications

Wipperfürth

Germany - 51688

For over 17 years the company GMTI, Golz Mould & Tools International UG, reliable producer of high-quality molds and dies for metal, plastic and rubber products for the Automotive industry and vehicle - Aluminum and zinc die cast parts such as axles, housing - Plastic parts such as bumpers, valves, headlight covers, manifolds, 2-component parts, etc. Lighting industry and electrical industry - Plastic parts such as sockets, switches and other lighting equipment Air and space industry and military technology - Aluminum, zinc die casting and plastic parts for high-precision requirements Medical - Custom-made of aluminum, zinc die casting and plastic for high-precision Requirements Furniture industry - Aluminum, zinc die casting and plastic parts such as handles, hinges, rollers, buttons, etc. Air + cooling technology - Rubber and silicone parts, seals etc. Machine Tools - Tools according to drawing We manufacture molds and tools for small - and large-scale production, as well as Prototypes The dimensions of the parts amount to 1 mm - 3,000 mm It can be processed part weights up to 20 kg. GMTI is an international company with manufacturing facilities in Eastern Europe (especially Poland) and Asia. Together with our cooperation company, we have a large number of experienced staff, from the designer to the machine operator. Through expert advice, a quality range of precision tools and on-time delivery, fr significant advantages to our customers.

Founded

1997

Employees

< 5

Certifications

Arnbruck

Germany - 93471

LEDERER Metall & Kunststoff GmbH has specialized in the manufacture of plastic injection molded products for over 60 years. Customers of LEDERER Metall & Kunststoff GmbH come from all areas of industry. For example, confectionery, cosmetics and stationery manufacturers have received design packaging. A large number of customers come from the handicraft, decoration, display and promotion sectors. In addition, the automotive industry in particular is one of our most loyal customers. With absolute fidelity to the original and under the strictest quality requirements, we manufacture vehicle and spare parts for classic automobiles exclusively for our customers. In close dialogue with its worldwide customers, "plastic in its most beautiful form" is produced at LEDERER Metall & Kunststoff GmbH.

Founded

1959

Employees

10 - 20

Certifications

Göppingen

Germany - 73037

Omni3D is the leading European manufacturer of large-format industrial 3D printers. With 10+ years of experience in industrial applications, we offer innovative solutions and comprehensive support for businesses across diverse industries. Our industrial large-format 3D printers unlock new possibilities for production, and tool creation in industries such as Railway, Automotive, Defense, Aerospace, and Maintenance, among many others. Experienced Team: A team of passionate specialists with 10+ years of industry experience and expertise in 3D printing. Award-Winning Technology: Our printers boast award-winning and patented solutions, ensuring high-quality and precise printing. Constant Innovation: We continuously develop and expand our offerings with new 3D printer models and materials. European R&D and Production: Guarantee of high quality and safety standards. We printed Parts with EN45545 Hl3/R1; HL3 R6, HL3/R22

Founded

2013

Employees

20 - 50

Certifications

Poznan

Poland - 61-119

Toolshop | toolmaker | family bussiness. 90+ fellow-workers | 60 tools annually | 30 years on the market Production of injection tools, moulds. Full service included (design, testing and qualification). Plastic components and machined parts production, mould shop with 30 machines. Mechanical solutions and design, product development, prototypes.

Founded

1990

Employees

50 - 100

Certifications

Dacice I

Czech Republic - 38001

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge