Mechanical assembly: receive an avg. of 7 offers per request

Discover specialized suppliers for mechanical assembly on Techpilot. Our platform connects buyers with suppliers who offer comprehensive assembly services for mechanical components. Use the e-sourcing process to find the best suppliers.

2543 suppliers for Mechanical assembly

The foundation of the company was Steeger 1948. After the nationalization of the company was privatized and has since been back in the hands of the Steeger family. With increasing business success was a range of versatile modernization and investments in new, modern and precise equipment such as √ CNC machining center, √ CNC press brake, √ tube punching machine and other production made. In addition to the subcontracting are now also increasingly re high quality custom products such as √ Storage Cabinets, √ bookshelves, √ 19 "cabinets and √ manufactured custom-made. To our motto of "Quality creates trust" to do justice, we certify our company according to the ISO 9000. On behalf of our clients, we manufacture supplier products for many areas of industry, such as: communication and vehicle technology. Be used while the modern machinery of our high tech production facilities. Thus, the company Steeger is capable of fast, flexible and according to customer requirements contracts in the areas of sheet metal and steel structures, metal stamping parts, sheet metal parts, CNC machined parts, as well as MIG / MAG / TIG welding perform.

Founded

1950

Employees

20 - 50

Certifications

Schwarzenberg / OT Neuwelt

Germany - 08340

In two companies, based in Oetisheim, we currently have approximately 35 employees. Our operational area includes the powder coating and printing (screen printing and pad printing) of metal and plastic parts. As a complement to our core business and to our customers to offer a complete service, we have developed a comprehensive system of production. In cooperation with you, we assume the purchase of raw parts, leave this edit to your liking of the respective companies, provide the perfect surface, apply the quality control and supply ready to install free home. Our customers include the automotive industry (Audi, BMW, Daimler-Chrysler, Porsche, Bentley, Volvo and VW), the electrical industry (users and housing manufacturer), metal construction, kitchen and home appliance manufacturers, as well as writing instruments manufacturers and customers from the air- u Space. We guarantee the long-term, value-preserving and decorative surface protection for your products, short delivery times and competitive prices for optimum quality. In our modern production facilities (investment in 2005 in a new location with state-of-the-art pretreatment u. Coating technology) quality surfaces are created in Oetisheim, see the world, even as far as Mexico, buyers. The primary criterion is and will remain our customers' satisfaction. This can only be achieved by a sustained high standard of quality, on-time production and delivery, and a trusting relationship with each other.

Founded

1983

Employees

20 - 50

Certifications

Ötisheim

Germany - 75443

Wesoma GmbH in Weimar Founded on 21.01.1993 by Dr. Günther Gerlach and Rainer Langer, the company initiated as managing partner until May 2007. In April 2007, Dr. Günther Gerlach adopted in retirement. As of May 2007, Mr. Rainer Langer is the sole managing director. It employs approximately 50 employees, including 5 in construction / project and 34 in manufacturing. Offered are the order-related development, design and production of devices and special purpose machines and components manufacturing according to customer drawings. Above average experience, extensive technology knowledge and a high degree of vertical put us in the position to suit the diverse customer requirements for design and manufacturing information on our business segments. For this is a powerful CAD technology based on Autodesk / Inventor - design software and a modern tailored to the performance profile of machines available. Quality, for innovation and reliability to ensure continuous and increasing customer satisfaction determine our corporate strategy and guiding principles for all employees.

Founded

1993

Employees

20 - 50

Certifications

Weimar

Germany - 99427

Our mission: precision, speed and absolute reliability! We support you from the idea to the finished product and serve small and medium-sized companies with our competence, creativity and maximum motivation.

Founded

2011

Employees

5 - 10

Certifications

Uffing

Germany - 82449

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

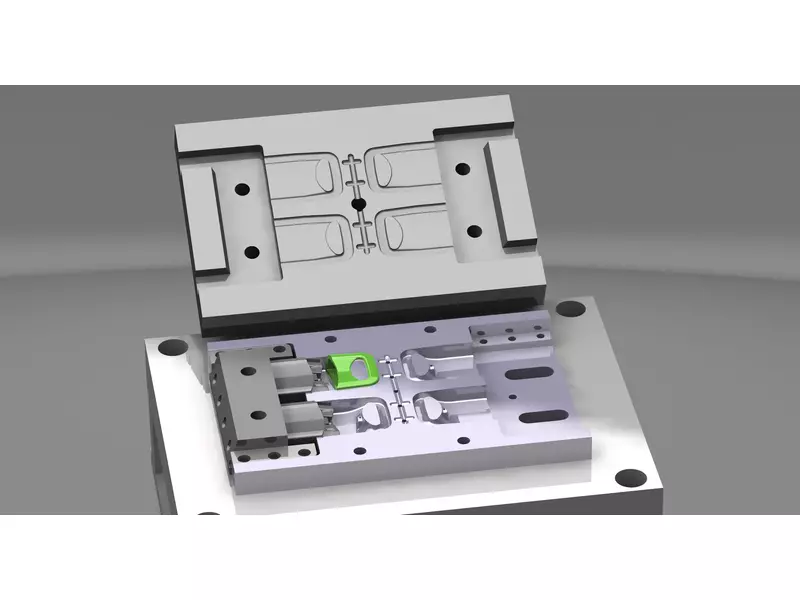

We are experts in the Mold Manufacturing Industry, with over 39 years of delivering quality products and offering our loyal clients only the best solutions. We pride ourselves with an ever-expanding technical background and qualified team at STAMPO. Our investment in the latest equipment and technology helps us to manufacture more demanding, precisioned products. Our certification ISO 9001:2015 supports our vision of customer focus, improved and updated management systems and general decision-making procedures. Our capabilities include: Molds: • Progressive Dies • Punching Dies • Plastic Injection Molds Services: • Wire EDM • Die Sinking • Small Hole Drilling EDM • Milling Services • Laser Marking • Laser Engraving Please contact us - we are happy to help and assist you!

Founded

1980

Employees

5 - 10

Certifications

ATHENS

Greece - 14452 METAMORFOSI

Raw castings made of aluminum alloys (AlSi) in the sand molding process under the highest quality standards for prototype construction or small series production up to a mold box size of 2.5 m. Your castings can also be further processed, measured and assembled directly via the new CNC machining center.

Founded

1937

Employees

20 - 50

Certifications

Königsbrunn

Germany - 86343

TEL Mechatronics (former Oerlikon Mechatronics) is the competent outsourcing partner for industry and research facilities in europe, with focus on ■Photonics ■Semiconductor ■Research Institutes We meet the highest cleanliness and quality standards of the mid and hightech industries. You find additional information on our scope of services and used technologies under the categories Services and Technologies.

Founded

1946

Employees

100 - 200

Certifications

Trübbach

Switzerland - 9477

welcome when Otto Weisleitner GmbH We are your specialist for mechanical engineering & manufacturing technology and are able to offer our services for: * Elaboration of concepts, 3D designs, calculations and dimensioning, CE marking * Production with turning, milling, grinding, water jet cutting, with focus - series production of rotary milling parts on state of the art combined lathes, milling centers, as well as the machining of large and long shafts up to max. Dm 500 x 3000 mm. * Pressing and welding * Assembly of modules to kopmplexen machinery * Sensors, pneumatics, hydraulics, drive technology * Maintenance, Servicierungen, repairs, alterations * Survey and reconstruction of machine parts * Advertising technology, product design, inlay work

Founded

1978

Employees

5 - 10

Certifications

Wiesing

Austria - 6210

RK-tec Klostermeier Maschinenbau e. K. stands for a company with highly qualified and motivated employees, which know-how solutions for new and existing systems in the area Machine / plant construction and conveyor technology supplies.

Founded

2006

Employees

20 - 50

Certifications

Aiterhofen

Germany - 94330

Since its founding in 1970 Wilvo has continuously evolved. The result being its current prominent role in the supply industry. Wilvo initially specialized in processing sheet metal parts and light construction and has grown into a important supplier for customers both in the Netherlands and abroad. Supplying a broad range of metal products, in large and small quantities, still forms the basis for Wilvo, but we like to look ahead too. Besides modern machinery, Wilvo possesses a lot of knowledge and craftsmanship. This allows Wilvo to complete both simple and complex projects within a short space of time.

Founded

1970

Employees

500 - 1000

Certifications

Bergeijk

Netherlands - 5570 AC

Gerhard Kurz Plastic injection molding Dr.-Muschak-Strasse 18 87600 Kaufbeuren

Founded

1996

Employees

10 - 20

Certifications

Kaufbeuren-Neugablonz

Germany - 87600

With 30 years of experience, CS Plastic is a valuable manufacturing partner for 2K and 3K injection molds, electric turntables and multi-component injection molded parts. From the concept to the design to the finished tool. Well-trained and experienced employees with a sense of precision and reliability determine our current performance potential. With well-founded know-how, we support you in the development of feasibility, use of materials and ease of maintenance.

Founded

1987

Employees

50 - 100

Certifications

Recanati (MC)

Italy - 62019

Schmidtke & Sohn Maschinenbau GmbH has been a proven supplier of spare parts and complete repairs for heavy and medium-sized industries since 1947. Our market position and our range of services enable the development and manufacture of special solutions for maintenance work on production facilities and spare parts. At the same time, we offer metalworking and the production of supplier parts for mechanical engineering as individual parts, small or large series.

Founded

1947

Employees

20 - 50

Certifications

Dinslaken

Germany - 46539

Our motto: Competence for your success! With about 200 employees, we are the most capable engineering companies in the region of eastern Bavaria. We create assembly and test systems for automotive, medical, white goods and information technology based on customer documents or develop the systems themselves. Products and services - Design, construction and plant - Mounting systems for small and medium-sized parts. - Robot cells with camera systems - Integ. Quality assurance (testing u. Testing) - Standard equipment according to customer specifications (build-to-print) - Contract manufacturing and assembly - Medical - Extruder for chem. u. Food Industry - Production of Manometerlaufwerken General Info Our core competencies lie in the design, manufacture and installation of sophisticated mechanical engineering components or complete systems with high quality requirements. We have particular experience in the use of robots and image processing systems. Integrated quality assurance by measuring and testing technology is self-evident. Our location at the motorway junction Deggendorf guarantees an easy access to the main industrial sites in Bavaria.

Founded

1984

Employees

200 - 500

Certifications

Metten

Germany - 94526

Production of cast iron components 1. EN 1561 GJL-150, GJL-200, GJL-250, GJL-300 2. EN 1563, GJS-400-18, GJS-400-15, GJS-450-10, GJS-500-7, GJS-500-7, GJS-600-3, GJS-700-3, GJS-800 -2, Low Temperature: GJS-400-18LT, GJS-350-22-LT 3. EN-GJS-SiMo: No. 5.3111 / 5.3112 / 5.3113 / 5.3114 / 5.3115 / 5.3116 / 5.3117 / 5.3118 / 5.3119 Piece weights: from 0.2 to 45 kg for gray cast iron (GJL), 0.2 to 26 kg for ductile iron (GJS) 10 x DISA vertical moulding lines in the group. Max box size: 850 x 650 on DISA 250C Further processing with 140 CNC machines Assembly Coating: own KTL system, powder coating Offers from approx. 200 parts per year

Founded

1927

Employees

> 1000

Certifications

VIVIER AU COURT

France - 08440

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our corporate objective is to achieve the greatest customer benefit. Benefits means the best possible advice and planning for the customer as well as the production of rotary and cubic components at competitive prices with absolute top quality for us. The company offers comprehensive manufacturing capabilities in various mechanical fields , such as: - CNC mill with a working area of 1,020 x 600 x 600 mm - CNC turning with a diameter range of 1-200 mm and a turning length of 600 mm - CNC wire cutting with a working area of 500 x 350 x 400 mm and a wire thickness from 0.2 mm - Surface grinding with a working area of 600 x 400 x 322 mm and an accuracy of 0.001 mm The production include also all the needs of precision mechanics for the metalworking industry. Due to the very low operating costs In addition to the machine-hour rates are extremely low. Due to the great depth of production sprinklers tooling AG can offer a comprehensive selection of production considerably lower prices than that of the competition. A collaboration can take place at different levels. Be it to break production peaks or outsource complete manufacturing steps. This requires flexible, cost-effective and competent partners like the Sprenger AG tooling that performs this production steps.

Founded

1993

Employees

Certifications

St.Margarethen

Switzerland - 9543

Dear ladies and gentlemen, As an expert in the field of the metal industry, we would like to present our services to you. With over 15 years of experience, we support companies such as our subsidiary Raumsysteme Grob. We produce around 1500 containers per year. Companies like yours are also in the process of solving goals or problems and achieving long-term success. Our company is characterized by our high quality, which enables us to offer our customers according to your wishes, quickly and always to the point. Our services include: welding technology, punching, laser cutting, edge bending and folding, CNC turning, CNC milling, powder coating and industrial painting. We would be happy to explain to you more about our services and their specific benefits for your company in a personal conversation. We cordially invite you to contact us to make an appointment. We look forward to working with you and contributing to your success. sincerely

Founded

2009

Employees

10 - 20

Certifications

Aindling

Germany - 86447

DS-Technic designs, builds, programs and commissions workstations and production lines. We also offer modification, modernization and service of existing machines and implementation of new types of products on existing lines. We have our own tool shop equipped with the latest equipment and a laboratory equipped with a precise 3D measuring machine. Thanks to them, we produce parts for the devices we design as well as elements for customers, both on the basis of the documentation provided and use of reverse engineering. We encourage you to establish cooperation in the field of not only designing and manufacturing entire production lines, but also making elements that require milling, die-sinking EDM and welding. We undertake to make details both in single and prototype production, for e.g. inaccessible spare parts for machines, or serial production regardless of the degree of complexity. We also offer CMM measurements of finished parts. We offer special solutions, tailored strictly to the requirements of customers, developed through deep technological analysis, and then creating a solution concept which evolves in close cooperation with the client. This approach ensures achievement of contractual goals. We have extensive experience in cooperation with renowned companies, mainly from the automotive industry, but not only. We offer the following services: • CNC milling, • Turning • Grinding • Die-sinking EDM, • Welding • CMM and optical measurements. Machinery: DMG CNC milling centers: DMU 1150V: 3-axis with working area 1150x700x550 [mm] DMU70 eVolution: 5-axis with travel 750x600x520 [mm]. Die-sink EDM SODICK AG60L with the possibility of machining a workpiece with dimensions of 950x740x450 [mm] Conventional lathes with machinability (dia.x length) 450 x 1500 [mm] Surface grinder with dimension max. 200x600 [mm] Roller grinder (dia.x length) 250 x1100 [mm] Hole grinder (dia.x length) 200 x200 [mm] MIG/MAG/TIG welding We provide high quality of workmanship thanks to our own measurement laboratory, equipped with: • Mitutoyo Crysta Apex V9106 – 3D coordinate measuring machine – measuring range 900 x 1000 x 600 mm • Mitutoyo QUICK-SCOPE QS-L 3017Z – vision measuring system • Mitutoyo HR-320MS – stationary hardness tester • Mitutoyo SJ-411 Portable Roughness Tester, equipped with touch screen and integrated printer • Mitutoyo LH-600E digital altimeter • Mitutoyo granite slab class 00 dimensions:2000x1000x220 [mm] • Mitutoyo sets: diameters, micrometers, reference plates, depth gauges, sensors, digital calipers We encourage you to send inquiries to the produkcja@ds-technic.com address. We guarantee quality and punctuality. Website: www.ds-technic.com We will be grateful for the opportunity to present our services more widely at your headquarters. If you have any questions, don't hesitate to contact us directly.

Founded

2011

Employees

10 - 20

Certifications

Kraków

Poland - 30-858

Everything for the success of our customers Since 1993, we convince our customers with many strong arguments: the combined expertise in plastic, plastic assemblies, system assemblies, tooling and services. Not without reason do us both medium-sized companies and large international corporations from diverse industries to appreciate as a powerful partner. Everything from one source As an experienced system partner, we offer you a wide range of tried and proven standard products, customized solutions and comprehensive service. Competent consultants and qualified application engineers guarantee it active, continuous assistance from the optimal choice of products to complete system solutions. Put it all together more You can expect more from us: We develop tailor-made solutions - and across a variety of materials and product groups.Positive side effect: Thanks to this process-oriented approach there is the additional opportunity to create important synergies and possibilities for substitution. Everything you want Behind the terms plastic, plastic assemblies, system assemblies, tooling and services hidden in Siebrecht an enormous range of individual, also safe for you interesting products and solutions. Do the best for yourself what our diverse range. All along the process chain Since in finding solutions in our house, the process concept is at the forefront, it is natural for us to provide our customers throughout the entire process chain - to provide advice and practical help - from the planning stage through to implementation to delivery. Depending on your needs, we agree together with you, our comprehensive services will depend on your specific needs. Everything when and where you want Through intelligent logistics systems and a computerized warehousing, we can easily adapt to your specific planning procedures.An extensive warehousing guarantees for standard parts, a short-term availability. Even e-commerce solutions and EDI / VDA interfaces are on our system landscape at any time mappable. All who trust us The narrow, mostly long-term cooperation with customers from different industries is clear evidence of the reliability of our products and our cross-industry expertise. Priority areas for which we are working: commercial vehicles, automotive, craft, lighting, construction, medical, and much more All you want to know Whatever your requirement - you are in good hands. Personal, competent contacts assure an intensive all-round support and superior service. When you convince yourself of our performance? Discover new potential for your success - with us as a strong partner! We look forward to you and your job.

Founded

1993

Employees

20 - 50

Certifications

Diepholz

Germany - 49356

Thanks to our many years of experience, we now produce and market a wide range of medium and large-sized turned and milled components for sectors that range from cars to machine construction, welding, dentistry, medicine, automation systems, and oil-dynamic and hydraulic systems.

Founded

1978

Employees

20 - 50

Certifications

San Lugano (BZ)

Italy - 39040

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge