Mechanical assembly: receive an avg. of 7 offers per request

Discover specialized suppliers for mechanical assembly on Techpilot. Our platform connects buyers with suppliers who offer comprehensive assembly services for mechanical components. Use the e-sourcing process to find the best suppliers.

2543 suppliers for Mechanical assembly

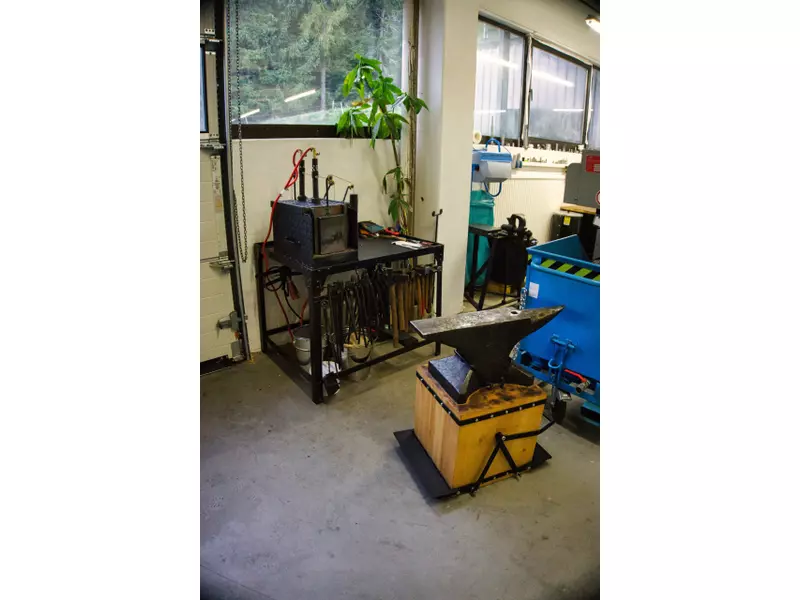

As M + L Werkzeugmaschinen GmbH, we have our origins in the wholesale trade in machine tools, but over the years we have discovered that due to the increasingly demanded individuality, adaptation work on the machines has become necessary. Based on this, we were allowed to undertake milling and filming in our small production. In addition, we received more and more inquiries from customers about the acquisition of small series and single-part production, which did not want to invest in machinery for the time being. In 2018, we decided to create our own platform under the CNCwerk brand. In addition to the production of milling and turned parts, we also like to offer you clamping solutions in jig construction and supply complete assemblies. Founded in 2004, as an expert in milling and turning technologies, we can offer a very good overall package of modern machinery, effective clamping solutions and tools with a wealth of experience from our employees. Talk to us and see for yourself! http://ml-cncwerk.de/kontakt/

Founded

2004

Employees

10 - 20

Certifications

Hartmannsdorf

Germany - 09232

Founded

1992

Employees

50 - 100

Certifications

Chemnitz

Germany - 09116

We are able to deliver any kind of mechanical parts or assembled units at the time agreed and with budget control, according to the technical specifications required by the costumer, starting from engineering drawings and a bill of materials in any format.

Founded

1989

Employees

20 - 50

Certifications

SANT'EGIDIO DEL MONTE ALBINO (SA)

Italy - 84010

Founded

Employees

10 - 20

Certifications

Geretsried-Gelting

Germany - 82538

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

The BKM precision tools, punching and bending parts GmbH was founded in 1977 and stands below with you: 1) Products: - Leaf Spring / keys springs - Connection, threaded and welded parts - Stamping and bending parts - Contact parts and springs, with or without rivet - Wire parts - Spring-loaded terminals and special bending springs - Coal guidance / mounting hardware (mounting small components.) 2) Dimensions: - Material thickness: Band 0.05 to 5 mm - Wire Ø 0.1 to 6 mm - Lengths up to 400 mm 3) Materials: - St-material - Carbon steel - Stainless steel (1.4310/1.4301) - Non-ferrous metal (bronze, brass, copper) - Special alloys 4) finishing: - Harden, even bainitic - Case hardened - Surface treatment (Vibratory grinding / polishing / start) - Galvanic surfaces 5) Industries: - Automotive - Electrical industry - Household appliances - Entertainment Electrical - Toys and Leisure Industry - Medical - Solar 6) departments / facilities: - Construction (development) - Tool (also prototype) - Presses with up to 125 tons. - Punching and bending machines up to 25 tons. (Bihler, Wafios) - Tempering - Trowalanlagen - Sorting by a camera system 7) Certifications: - Certified according to ISO 9001:2008 and QuH (Environment) - TS 16949 in preparation "All in one" is the motto of our house. Already on offer stage, we can provide valuable recommendations to product improvements or cost reductions by simplifying the design, appropriate material selection or tolerance definition you our years of experience. More than 100 competent and committed employees in management, engineering, tooling, manufacturing and quality assurance take care of the optimal realization of your wishes. Corporate objectives BKM has been successful for over 30 years in the field punching, bending and contact parts, leaf springs and wire form parts operate. Our business goals are * Customer Satisfaction * Motivated and satisfied employees * Latest Technology * Expansion of market shares and * Protecting the environment

Founded

1977

Employees

100 - 200

Certifications

Schwabach

Germany - 91126

The BOZ Group specializes For more than 40 years in a "high clean & high end" markets in steel, stainless steel and aluminum semi-finished products from simple to complex assemblies BOZ Group offers the full Automatic Production with versatile robots are used in bending, welding, laser welding and powder coating. Structured Engineering & Industrial Services (from prototype to Zero Defect Production) - Proto Series - Upgrade Series - Zero Defect Series Which service level agreement suits your requirements DETERMINE YOUR RQ-INDEX WITH OUR APP World Class Manufacturing: World Class Manufacuring has as target 100% perfecte logistics as well as a Lean producktionseinrichtung Total productive Maintenance (TPM) and 5S The BOZ Group is among the top 10 in Europe We take the liberty to give you our digital brochure on Anfage have to offer. You can also take a virtual tour through our company do to get yourself a picture of the opportunities available: http://www.onsite360.nl/projecten/bozgroup2009/index.html. You will find that we have a high quality machinery for items for small series as well as the universal robotics for larger batches. We offer the following services such as: cutting, bending welding, edit to the painting of parts and assemblies The machining of parts such as milling, turning, grinding to paint individual parts The combine incl mount of machining parts and supplier parts to complete assemblies. For this we have the most modern facilities such as: laser cutting machines and Ponsen for stainless steel, steel and aluminum, Stopa including sheet metal storage system with 430 storage locations. bending machines up to 6 mm thick and 3,000 * 1,500 mm (LxW), manual and robotized. Trumpf laser welding cells with Kuka robots MIG / MAG / TIG welding cells. deburring, Einpressanlagen machining centers (turning, milling, grinding, etc.) Automated and robotic powder guns-paint, surface treatments. The latest control and measurement devices succeeding the highest quality standards. assembly equipment for assemblies and larger components to serial assembly. Our specialty is delivering high-quality as well as aesthetically perfect products, parts, assemblies, to subsystems for various industries. Our JIT delivery reliability is a concept as well as the consequence of the delivered quality, customer satisfaction and the interesting price-quality ratio.

Founded

1972

Employees

50 - 100

Certifications

Bergen op Zoom

Netherlands - 4612 PL

The company LUWINOX is a competent, dynamic company which specializes in the processing of stainless steel in various grades. We look back on many years of experience in plant construction, construction of heat exchangers, piping, fittings, profile constructions, metal structures, as well as contract work in the field of welded assemblies, laser and metal parts. We also offer design services, design of heat exchangers, Design of system parts and FEM calculations. This work is carried out by our in-house design department. We always strive with modern manufacturing techniques and well-trained staff to ensure the best for our clients quality of our products. Our design department will accompany you in your projects on the latest technical level, from planning to the finished object. Satisfied customers are the best proof for good work.

Founded

Employees

5 - 10

Certifications

Tanna

Germany - 07922

We are a small master company in the field of mechanical engineering, specialized in the production of turned parts and 3D printing. In addition to the production of individual parts and small series, our strengths also include the creation of 3D files, plans and the retrofitting of parts.

Founded

2017

Employees

< 5

Certifications

Fichtelberg

Germany - 95686

Our innovative company has its core competence in the individual manufacture of special machines. Our know-how is particularly characterized in the area of development and production of prototypes, samples, individual parts, assemblies, small and medium series.

Founded

2019

Employees

10 - 20

Certifications

Siegsdorf

Germany - 83313

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

Employees

20 - 50

Certifications

Hildesheim

Germany - 31137

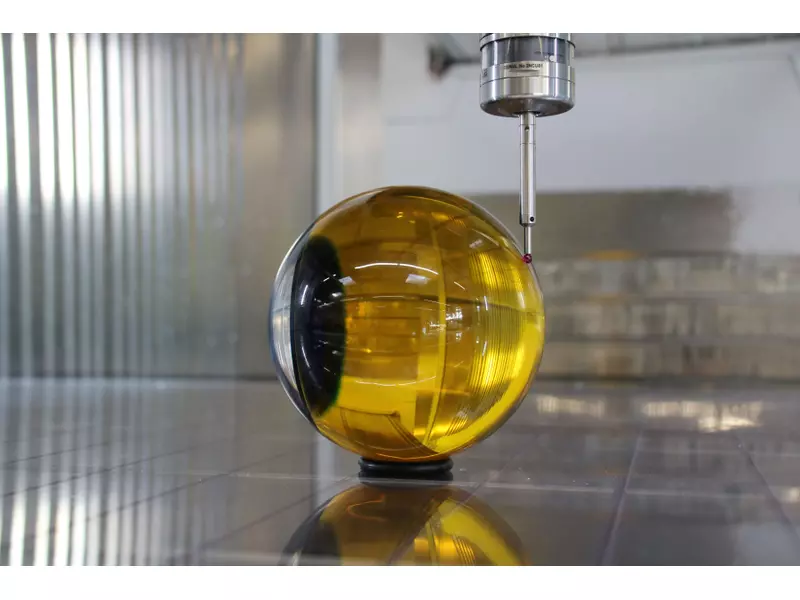

EPM & construction machinery KG was founded in 1995 as a technical office of Peter Plien. In the beginning created designs for special grinding and deburring. Since the orders were becoming more extensive, we expanded the company after two years at 100% design capacity. During this time, sawmill machines and their operation and funding designed projects directed and accompanied montages. Our field of activity also expanded in the fields of precision engineering, measurement and testing. In 1999 the company moved to new premises, in addition to our technical office there was our mechanical workshop. Now we can start with the production of our self-developed machines, so at the beginning special machines developed according to customer needs. A conventional machinery for drilling, turning and milling was original equipment. In 2001, we expanded our production facilities to CNC machines in order to better meet the needs of our customers. Since 2002 we have been nurturing emerging from the profession of industrial mechanic in precision. In the future, EPM construction & machinery KG should be increased by a further field of activity: EPM-RACING. Main feature of this new department will be the production of RC-CAR-tuning parts and internal combustion engines. The development, design and production of prototypes of various kinds is our strength; reputable companies from different sectors, such as John Deere, Actemium - Vinci and L'Orange rely on our tailored exactly to your needs solutions. Area measurement, inspection and assembly Combined measurement testing and assembly places for fine mechanics and hydraulics Combined measurement testing and assembly systems for vehicle transmissions and clutches Combined measuring equipment for testing and assembly hydraulic control blocks Design of individual workstations with screwing High pressure leak test up to 4200 bar hydraulic Leak test for oil pans, gear cover and the like Handling area Loading of presses Development and construction of special grippers for handling and portal robot loads of up to 120kg Field assembly and disassembly Special assembling machines for bearings and bushings Special machines for dismantling of valve seat inserts in cylinder heads Screwdrivers - handling up to 4000 Nm torque The field of packaging Salt tablets in aluminum foil packaging Hygiene products packaging Field component manufacturing CNC

Founded

1995

Employees

< 5

Certifications

Neustadt/Wst.

Germany - 67433

ProcCon ... ... Is active in environmental and operates new developments and projects for the gas station area, including manhole covers, manholes, Fernfüllschächte, special manhole covers and other special solutions according to length. The products are manufactured according to the requirements of the Water Resources Act. ProcCon ... Operates ... joint venture projects as subcontractors in general machine construction, steel engineering, plant engineering, sheet metal work, piping, fixture and special machinery. In the sales order steel structures, machine frames, welded parts, air ducts and machine elements are manufactured (Including industrial platforms, industrial pallets, welding frames, kiln cars, bunk car, butterfly valves, louver dampers,). ProcCon ... ... provides engineering services for your Untenehmen, among other things, project management, development and construction 3D/2D (SolidWorks, AutoCad) in machine and plant engineering. Prototyping, prototype, create manufacturing and assembly drawings, detailing, bill of materials Products: Prototype of a descaling; prototypes cleaning hoods for sheet cleaning, assembly of a spindle; assembly cars, machinery elements, oven and dryer cars, platforms, pipelines, production range: wheel block; storage tank / filter; Framework; dryer baskets, pallets, throttle / Blinds; pipes / ducts, manhole covers; manhole remediation; b

Founded

2003

Employees

Certifications

Iserlohn

Germany - 58636

Custom-Made Solutions for Individual Products In accordance with customer demands and wishes, ISOVOLTA – in addition to manufacturing high-quality laminates in the form of sheets, tubes and rods – also offers processing of thermoset materials. Different materials are shaped by processes such as cutting, grinding, drilling, turning, milling, gluing, mounting, punching, jet cutting or painting according to individual customer specifications. Based on our expertise in material-specific selection and production-technical implementation as well as our years of experience in job shop, serial, and mass production, we are able to develop the best possible process for each product. Range of Materials Phenolic Cellulosic Paper / PFCP Phenolic Cotton Cloth / PFCC Phenolic Glass Cloth / PFGC Melamine Cotton Cloth / MFCC Melamine Hard Glass Cloth / MFGC Epoxy Glass or Glass Roving Cloth / EPGC Epoxy Glass Mat / Polyester Glass Mat / EPGM / UPGM Melamine-Lined Hard Paper / MKHP / INBORD® Silicone Glass Cloth / SIGC Special Laminates / Special Materials / CFRP, KP, PIGC MAGNOVAL® CONT AVAL® GX_11.3309 GWS RP High-Performance Rings GF-UP / GF-EP ISOVAL® R-AL Competence in Soldering Equipment Soldering Frames are primarily used to transport PCBs in soldering machines while simultaneously fixating “through-hole components” by using Top Hat Systems. With our specially developed ESD material, which is able to endure high temperatures and chemical resistance, the ISOVOLTA Soldering Frames are able to withstand thousands of soldering cycles. ISOVOLTA Soldering Frames and masks are custom-made innovative products. The design of the mask is defined by the PCB, the machine and the customer`s requirements. Possible combinations of the ISOVOLTA Universal Frame, ISOVOLTA Soldering Frame and the ISOVOLTA Flexible Suppressing System. (ISOVOLTA Suppressing System: ensure suppression and alignment of critical PTH components.) Combination ISOVOLTA Soldering Mask and ISOVOLTA Suppressing Panel for reliable and accurate alignment of PTH components. Innovative solutions guarantee quick and comfortable handling. Product combinations Top Hat Systems Universal Frames Flexible Top Hat System Magnetic Carrier Coating Frames Pressfit Tools Router Tools Hand Soldering Tool

Founded

1969

Employees

100 - 200

Certifications

Wackersdorf

Germany - 92442

A successful family-owned company: Focusing on people Since 1949 the family-owned company of Pöppelmann, with its five production sites and 550 injection moulding machines, thermoforming lines and extruders, has grown into a leading manufacturer in the plastics processing industry. In more than 90 countries people value the quality we offer, “made by Pöppelmann”. Our success is down to our team of over 1,700 highly-qualified employees.

Founded

1949

Employees

> 1000

Certifications

Lohne

Germany - 49393

Your competent partner for CNC turned parts and CNC milled parts Our company was founded more than ten years ago in Korbach. We currently employ a staff of seven, in the 1 - to 2 working shifts. Our expertise lies in the production of precision parts in prototype and pre-and small series. We process high quality materials, work fast and reasonably priced and available for short term through our own delivery service. Through an annual investment of our machinery has been steadily expanded and modernized to meet the high market demands can. On materials we process primarily - Steel, eg St37, St52, C45, 9SMn28PbK - Tool steel, eg 1.2379, 1.2842.1.7225 - High-strength steel, such as titanium - Stainless steel, eg 1.4305, 1.4571 - Non-ferrous metals such as brass (MS58), gunmetal (Rg7) - Aluminum (Round / plates), forB. AlCuMgPb, AlZnMgCu, AIMgSi - Plastics, eg POM, PA6 A constant stock of semi-finished products in various dimensions and profiles allows us to react quickly to meet your needs. Production DFS Weidemann offers complete production, ie the semi-finished or blank out the turnkey component. Add custom work we produce for you: - Prototypes and assemblies - Small and medium series - Complex workpieces with high quality requirements of form and position tolerances Certified partner companies take us for case hardening, induction hardening, plasma nitriding, etc. CNC turning technology For more than ten years, we manufacture both simple and complex parts on modern, technically advanced CNC lathes. For example, we can manufacture aluminum turned parts up to diameter of 350 mm zueinem.In addition, a complete machining of parts 3-42 mm diameter of the rod, to 300 mm in the feed and in length up to 635 mm. Small and medium-sized batches are our particular strengths. CNC milling technology Our extensive range of machinery for a variety of requirements forms the basis for an optimal production process. The CNC machining is up table size 1000 x 500 mm. From custom-built or complex workpieces, always operating with highest precision and accuracy Surface Technology Our services also include the surface treatment of various materials: - Burnishing - Strahlläppen - PVD coating - anodizing - hard anodizing - Chromate - zinc and chromate - Liquid Coating Heat treatment Our workpieces are heat treated for the targeted setting their properties. The performance and service life of a tool is decisively influenced by the heat treatment. As services we offer - Salt bath treatment - Vacuum treatment - Plasma - nitriding - shielding gas treatment

Founded

2003

Employees

5 - 10

Certifications

Korbach

Germany - 34497

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

The Erwin Quarder group is a powerful, innovative partner in the plastics sector with a total of 400 employees and 55 injection molding machines (up to 400t). The Quardergruppe is divided into three divisions automation, tool and technology. From the development, design, mold manufacturing, automation, production and assembly of the modules, the whole process is in the house. We offer this service like also separately. Production range: * Precision injection molded parts * Multi-component parts * Insert Technology * Flex film technology * Tandem technology (also in conjunction with MuCell) * Assembly injection molding * Miniature injection molding technology We process all common thermoplastics. We have been successfully cooperating with several universities and Forschungsinstuten and have their own patents / Developments developed to series production. In the south of Germany to settle in Kirchheim / Teck was founded. Products: Technical Products * Power Strips from LCP for Harting * Feeder Fountain Pen Montblanc * Rear suspension locking system for Ford * Connectors G+ H * Mounting for system components Ford * Bottle holder Mapa * Mouth plate for Mapa pacifier * Rover ignition switch * Half-shell connector for Siemens cell phone * Connectors * Components for SIM CARD Reader Siemens * Component for medical instruments Medical * Component for medical instruments Component technology * IR receiver housing * Lock cover BMW 3 Series * Component lock housing VW Sharan * Gear cap Volkswagen * IR transmitter Peugeot * Key frame Miele * Key set for Blaupunkt radio * Housing for engine electronics companyHarting Insert- * Gearbox cover * Hall IC * Bobbin * Lock housing Daimler-Chrysler S-Class * Mirror adjustment Daimler-Chrysler * Lock cover Toyota Avensis * Lock holder Daimler-Chrysler S-Class Assemblies * MID-housing Film insert molding - MID * MID-housing * Valve Plug Automation Technology * Transfer station for Flexible PCB to insert a hand * Detail view of a production facility for electrical component support for the automotive industry * Automatic feeding and separation of connector lugs * Kuka industrial robot * Loading and unloading hand for the parallel loading and unloading of the tool

Founded

1971

Employees

200 - 500

Certifications

Kirchheim/Teck

Germany - 73230

Your specialist and suppliers for the machinery, plant and equipment as well as vehicles and steel structure is ansessig with over 100 employees in the Lower Allgäu in Schöneberg. Our qualified staff in the areas of milling, turning and steel construction make it possible to manufacture large-scale projects based on customer drawings and deliver ready to assemble in no time. Many years of experience and quality awareness of our employees in steel as well as in mechanical production and the connected paint make it possible to produce assembly capable modules with highest precision.

Founded

1960

Employees

100 - 200

Certifications

Pfaffenhausen

Germany - 87772

Experience and Innovation More than 30 years of experience in the field of metal processing form the basis for our daily business. National as well as global industrial customers from various industries, we count among our customers. We manufacture and procure almost everything is manufactured from metallic materials or plastics. We support the mission of the advice on the drawing (CAD / CAM) to the finished product. Latest technologies, advanced manufacturing equipment and our courage to innovate guarantee the highest quality.

Founded

2007

Employees

20 - 50

Certifications

Widnau

Switzerland - CH-9443

ZN-Metall GmbH, based in Teising, was founded in 2016 by Andreas Nold and Christian Zerbin. In the meantime, the production area has been expanded to a total of approx. 3.000 qm with a second location in Heldenstein. Our modern machinery, consisting of innovative machining centers, meets the highest requirements for all production components. This wide range of production, our motivated team and many years of experience in metalworking make us your ideal partner when it comes to manufacturing all types of components — from prototypes to series production — from individual parts to small and large series In our profile processing processes, we specialize in non-ferrous alloys. In this way, we combine our strengths and guarantee proven quality — tailored to your individual requirements. As a metal processing company, we produce according to your drawings in the required quality at competitive prices. In doing so, we always pay attention to the best compromise between optimal resource conservation, economic efficiency and production processes. For us, effective work processes are an essential part of order processing. From the blank to the finished product, we deliver everything from a single source.

Founded

2016

Employees

20 - 50

Certifications

Teising

Germany - 84576

For us, everything revolves around the topic of plastic. Birkholz has been counting for decades among the most experienced and efficient processors of transparent thermoplastics. We offer you a wide range of cutting-edge plastic processing processes, materials and unique finishes. With Birkholz, you benefit from extensive knowledge, outstanding expertise and cutting-edge technology!

Founded

1936

Employees

10 - 20

Certifications

Heppenheim

Germany - 64646

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge