Spot welding: realize better purchase prices

Find specialized suppliers for spot welding on Techpilot. Our platform offers access to suppliers who use this welding technique to create strong and precise connections. Benefit from an efficient e-sourcing process and better purchase prices.

1075 suppliers for Spot welding

Targeted product presentation is the basis for successful sales promotion! Sales promotion knows no boundaries. Dude works throughout Europe. For a variety of clients. For the different markets. And for the most diverse requirements. Experience, innovation and strict customer orientation are also internationally solve the guarantee of first-class sales promotion products, the individual tasks individually. With goods carriers of various kinds to Dude sees itself as a competent partner for trade and industry. For a variety of backplane systems such as grids, slat, perforated panels and piping systems are extensive opportunities of sales promotion goods carriers available - and the stock. In addition, dude developed in close communication with its partners continuously new elements of your sales promotion. Each employee Dude is your personal sales promoters. Dude thinks.Hand in hand Your Dude contact works together in the planning and production of our shelves with you. It provides comprehensive advice and provides the impetus for innovative and successful product presentations, which ensures contrasting with the competition promotion. Good sales promotion ideas, we implement consistently. Unconventional tasks we take on as a challenge. Sales, planning and production are at dude in constant dialogue with each other. So your goods carrier arise uncomplicated, non-bureaucratic and directly. Only by first-class technology is successful promotion conceivable! Whether large numbers, or individual small series: Dude uses cutting edge technology to their advantage. Our well-equipped tooling, sophisticated manufacturing and own surface finishing production lines guarantee your goods without intermediate steps. Complete with dude made.With us, you get everything from one source - quickly. Just typical dude! Our overall performance ensures the efficiency of your sales promotion. In Dude, the whole is more than the sum of its parts. Through a customer-oriented way of working, persistent and purposeful exchange of information between our employees and the entire production under one roof we manufacture your products marketable equitable, timely, high quality, yet inexpensive. Our goods carriers are a unique feature of your entire sales promotion.

Founded

1852

Employees

200 - 500

Certifications

Altena

Germany - 58762

Grafos Steel is a leader in the production of industrial stainless steel keyboards, control panels and chassis for their housing. In addition to offering a wide range of standard products, the company specializes in the constant development of tailor-made solutions for industrial computing, able to satisfy any type of customer request. In a constantly changing market, the patented technologies and products designed by the Grafos Steel technical laboratories are a guarantee of superior levels of quality, reliability, comfort and precision. This is the trademark of a company that continuously invests in research and development and constantly aims at improving production processes.

Founded

2001

Employees

50 - 100

Certifications

Formigine

Italy - 41043

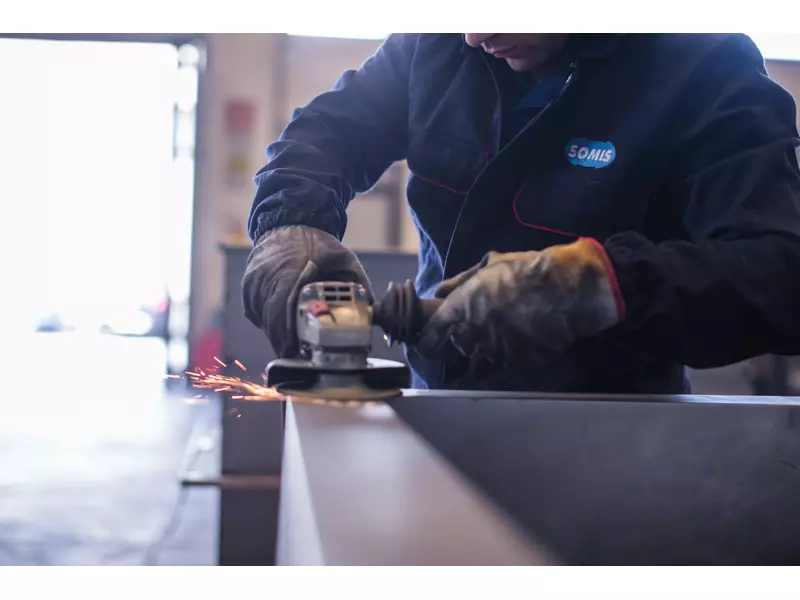

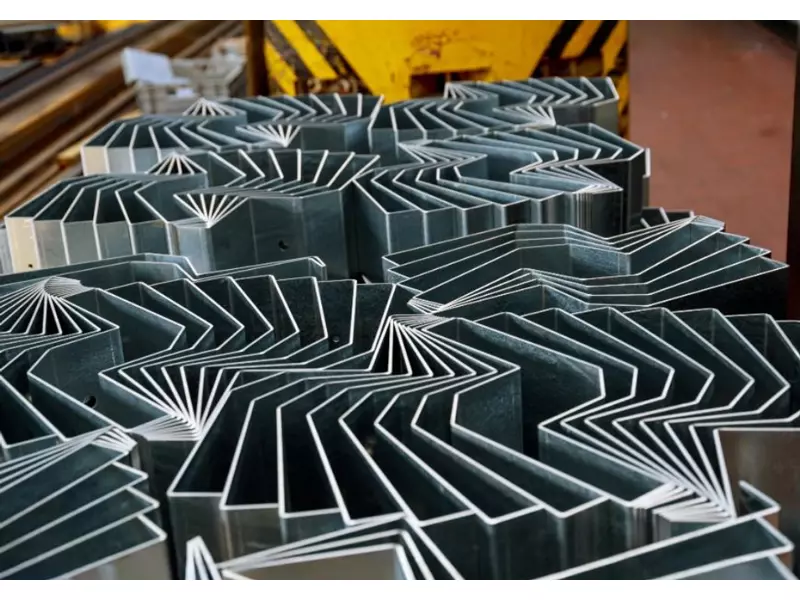

Somis is a company specialised in medium and light metal structural work and in sheet metal processing. It offers to customers the experience gained over the years, and provides with the best quality technical and project expertise (3D drawing), always able to satisfy customers’ needs. With the knowledge gained it can propose to new clients with the aim to increase production, declaring till now the availability to examine with competence and proficiency any client’s needs. Somis is a dynamic company, equipped for the various metal structural works, whose systems provide high quality and quickness in the execution of finished goods at very competitive prices.

Founded

1996

Employees

50 - 100

Certifications

Fossalta di Portogruaro

Italy - 30025

At L + M, every customer will find their own “menu”! Whether contract manufacturing, either carried out in Switzerland or Slovakia, or overall projects from advice to the installed product. L + M = A la card - customer in focus! No matter how you decide, you will receive personal advice from us, the person responsible for sales remains your personal contact person until delivery. Market services: our competencies - your benefit Advice: We develop solutions from one source based on your ideas and needs. Engineering: proof of strength / FEM, 3D-CAD and conformity according to MRL 2006/42 / EG Production: series, tools and special constructions up to 15t or 9mx12m Production: locations in CH and Eastern Europe (> 4'000m² production and storage area) Welding technology: Our SFI + SFM guarantee welding quality at the highest level for steel, stainless steel and non-ferrous metals Quality: Evidence according to EN473 / ISO9712, customer approvals and project documentation Project management L + M Remigen: Excellent network of qualified partners and suppliers. In any case, we are your right contact from the region.

Founded

1962

Employees

50 - 100

Certifications

Remigen

Switzerland - 5236

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

INEX is a full-scope furniture producer with more than 10 years industry experience. For over a decade, we fulfill the highest standards of leading international retailers, consumer brands and furniture companies, with full in-house control of the whole manufacturing process.

Founded

2011

Employees

100 - 200

Certifications

Berlin

Germany - 10179

TINTEC Metal Technology is a certified welding specialist [DIN 3834-2, ISO 9001 iV] for holistic, sophisticated technology and complex welding sheet metal assemblies in steel, stainless steel and aluminum. We specialize in sheet metal fabrication for housing, container & industrial equipment, tanks & tanks, ducts & pipes / flanges and allocations, as a complete assembly with in-house development and design as well as our own production. Production chain with complete sheet metal technology from cutting (laser cutting, punching, shearing, burning) on the deformation (edges, bending, forming, rolling, rounding) with core expertise joining (GMAW, TIG welding, soldering, bonding) to the surface (grinding, brushing, galvanizing, paint / powder). Massive steel construction welding assemblies & to 6 tons with welding qualification according to DIN EN 1090-2 EXC 3 Complete production from one source from prototypes & item to small - medium batch & high quality craftsmanship at a reasonable price level with expert advice and customer care. The company was founded in 2006 with 10 employees is dynamically grown into a SME with now 45 qualified employees - from trainees on skilled workers, foremen and technicians to welding specialist and Welding Engineer. Currently, about 3,000 square meters of production area with stainless steel / mild steel separation and 15 integrated welding workstations for manual and semi-automatic MIG / MAG & TIG welding. (& Conveying equipment Food - - & Beverage, tobacco processing, filling,), air - space, ship, - & yacht building, vehicle and machinery - equipment - Regional and nationwide are demanding customers in the food industry & Apparatus reliably and continuously served.

Founded

2004

Employees

20 - 50

Certifications

Hilgermissen

Germany - 27318

WE-FORM unifies modern materials with innovative metal and tube forming technologies by delivering best components and modules to its customer– simply, adding value to your system. WE-FORM guides its customers from first ideation, product development, prototyping down to robust serial supplies. With headquarters in Austria and a financial sound private ownership structure, WE-FORM is a preferred partner to automotive companies and mobility system provider around the globe. With the direct integration of WE-FORM into REMUS in 2020, the „mobility“ competence is bundled and strengthened. Keywords: tube benders, tubing bender, tube bender, pipe bending, robotic welding, welding robots, welding robot, pipe bender, exhaust tube bender, tube bending, tubing benders tube forming, hydroforming, robot welding, exhaust pipe benders, pipe benders, hydraulic pipe bender, hydraulic pipe benders, hydroform, exhaust pipe bender, steel pipe bender exhaust tubing bender, tube end forming, cnc bending, bend tube, bending pipe, tube pipe bender, cnc tube bender, aluminum tube bending, bending steel tube, steel tube bending bending stainless steel tubing, stainless steel tube bending, tube bend, bending tubes, tube rolling, pipe bending services, tubing bending, cnc tube bending, copper tubing bender, copper pipe bender, cnc tubing bender, bending tubing, hydroforming process, cnc tube benders, metal tube bending, stainless tube bending, bending tube, bent tube, tube bending, companies, tubular hydroforming, tube bending services, pipe tube bending, high pressure forming, tube pipe benders, cnc pipe bender, pipe tube benders, bending tube steel, bending square tube, cnc pipe bending, tube bending cnc, forming tube, pipe bender hydraulic, tube bender hydraulic

Founded

1997

Employees

100 - 200

Certifications

Vandans

Austria - 6773

Since 1993, we are a Turkish steel market. As an experienced company in the field of stainless steel sheets and tubes, we give our customers good service and fast at cutting + bending of stainless steel materials. We have a large warehouse and a service center in the Turkish city of Izmir. We can customize your orders carefully, clean, fast and processed at low prices. For any questions please contact us at any time. With our subsidiary "Prosac" we operate in the following areas: - Sheet Metal Fabrication - Bending and folding - Laser cutting 2D

Founded

1993

Employees

10 - 20

Certifications

Izmir

Turkey - 35100

We are your specialist for pressing, stamping and deep drawn components for all levels and materials, welding (MAG, TIG, resistance welding), laser machining, nibbling, edging, drilling, tapping, processing all surface finishing, component assemblies.

Founded

1989

Employees

10 - 20

Certifications

Dietzhölztal

Germany - 35716

Founded

1992

Employees

50 - 100

Certifications

Chemnitz

Germany - 09116

Experts in Sheet Metal Fabrication / www.smates.mk / info@smates.mk / +389 71 305 806 At Smates, we specialize in precision metal fabrication, operating from a 2,000-square-meter facility equipped with advanced machinery. Each year, we process over 400 tons of metal, providing high-quality services to OEMs and manufacturers across Europe. Our team of experienced engineers and operators can work in three shifts when necessary, ensuring efficient production and minimal material waste to meet demanding project deadlines. We leverage cutting-edge technology, including 3D CAD software and SolidWorks, to design and optimize custom components for our clients. This allows us to deliver highly accurate and efficient solutions, no matter the complexity of the project. Our expertise and reliability have made us a trusted partner for EU-based companies, offering cost-effective and timely results. Our comprehensive range of services includes tube laser cutting, sheet metal bending, and powder coating. With a strong focus on innovation, Smates continuously invests in the latest technology to ensure we deliver the best fabrication solutions, helping our clients achieve their goals.

Founded

Employees

5 - 10

Certifications

Ohrid

Macedonia - 6000

The BKM precision tools, punching and bending parts GmbH was founded in 1977 and stands below with you: 1) Products: - Leaf Spring / keys springs - Connection, threaded and welded parts - Stamping and bending parts - Contact parts and springs, with or without rivet - Wire parts - Spring-loaded terminals and special bending springs - Coal guidance / mounting hardware (mounting small components.) 2) Dimensions: - Material thickness: Band 0.05 to 5 mm - Wire Ø 0.1 to 6 mm - Lengths up to 400 mm 3) Materials: - St-material - Carbon steel - Stainless steel (1.4310/1.4301) - Non-ferrous metal (bronze, brass, copper) - Special alloys 4) finishing: - Harden, even bainitic - Case hardened - Surface treatment (Vibratory grinding / polishing / start) - Galvanic surfaces 5) Industries: - Automotive - Electrical industry - Household appliances - Entertainment Electrical - Toys and Leisure Industry - Medical - Solar 6) departments / facilities: - Construction (development) - Tool (also prototype) - Presses with up to 125 tons. - Punching and bending machines up to 25 tons. (Bihler, Wafios) - Tempering - Trowalanlagen - Sorting by a camera system 7) Certifications: - Certified according to ISO 9001:2008 and QuH (Environment) - TS 16949 in preparation "All in one" is the motto of our house. Already on offer stage, we can provide valuable recommendations to product improvements or cost reductions by simplifying the design, appropriate material selection or tolerance definition you our years of experience. More than 100 competent and committed employees in management, engineering, tooling, manufacturing and quality assurance take care of the optimal realization of your wishes. Corporate objectives BKM has been successful for over 30 years in the field punching, bending and contact parts, leaf springs and wire form parts operate. Our business goals are * Customer Satisfaction * Motivated and satisfied employees * Latest Technology * Expansion of market shares and * Protecting the environment

Founded

1977

Employees

100 - 200

Certifications

Schwabach

Germany - 91126

The BOZ Group specializes For more than 40 years in a "high clean & high end" markets in steel, stainless steel and aluminum semi-finished products from simple to complex assemblies BOZ Group offers the full Automatic Production with versatile robots are used in bending, welding, laser welding and powder coating. Structured Engineering & Industrial Services (from prototype to Zero Defect Production) - Proto Series - Upgrade Series - Zero Defect Series Which service level agreement suits your requirements DETERMINE YOUR RQ-INDEX WITH OUR APP World Class Manufacturing: World Class Manufacuring has as target 100% perfecte logistics as well as a Lean producktionseinrichtung Total productive Maintenance (TPM) and 5S The BOZ Group is among the top 10 in Europe We take the liberty to give you our digital brochure on Anfage have to offer. You can also take a virtual tour through our company do to get yourself a picture of the opportunities available: http://www.onsite360.nl/projecten/bozgroup2009/index.html. You will find that we have a high quality machinery for items for small series as well as the universal robotics for larger batches. We offer the following services such as: cutting, bending welding, edit to the painting of parts and assemblies The machining of parts such as milling, turning, grinding to paint individual parts The combine incl mount of machining parts and supplier parts to complete assemblies. For this we have the most modern facilities such as: laser cutting machines and Ponsen for stainless steel, steel and aluminum, Stopa including sheet metal storage system with 430 storage locations. bending machines up to 6 mm thick and 3,000 * 1,500 mm (LxW), manual and robotized. Trumpf laser welding cells with Kuka robots MIG / MAG / TIG welding cells. deburring, Einpressanlagen machining centers (turning, milling, grinding, etc.) Automated and robotic powder guns-paint, surface treatments. The latest control and measurement devices succeeding the highest quality standards. assembly equipment for assemblies and larger components to serial assembly. Our specialty is delivering high-quality as well as aesthetically perfect products, parts, assemblies, to subsystems for various industries. Our JIT delivery reliability is a concept as well as the consequence of the delivered quality, customer satisfaction and the interesting price-quality ratio.

Founded

1972

Employees

50 - 100

Certifications

Bergen op Zoom

Netherlands - 4612 PL

As a small and highly flexible company, we have specialized in the classic fittings from metal. Our product range include: Window shutter fittings window accessories Door and gate fittings fish tapes construction bands box fittings Decades of experience, sophisticated and proven solutions, continuous product enhancements and intensive customer care by our field service characterize the company Pfeifer fittings. The specialized trade is our traditional partner. Only through service and professional advice quality can be made aware. Plant and pipeline construction We offer uncompromising quality in plant and pipeline. We offer expertise and abundant experience for the processing of stainless steel and steel the production of containers and pressure vessels, such as breweries, dairies and industrial Pipeline construction and industrial assembly We assemble, provide installation teams and supply components.Similarly, we are by our modern and comprehensive machinery able to provide complete solutions. Here punctuality and precision are guaranteed. Steel and metal We plan, design and manufacture custom-made for everyone: stairs balconies canopies carports Light and heavy steel structures and platforms For your construction projects, we create the right solution. As your partner for difficult building projects we are at the planning stage to the side and find the 100% solution in terms of quality, cost and design. Mechanical Production Take advantage of our expertise and our extensive range of equipment. According to your specifications we manufacture single and serial parts. Our experienced staff is well versed in the areas of turn mill welding mount From the manufacture of individual parts to the complete equipment, our comprehensive performance and flexibility to tough competitive prices and with the highest quality available. sheet metal working In the field of sheet metal processing, we offer the following services: lasers Flame cutting roll Edges up to 5 meters welding With our machinery and a professional staff we are going in the usual flexibility to your wishes and requirements. Through our well-stocked raw material warehouse, we are able to produce within a short time and deliver. surface treatment The surface treatment of steel and steel parts has been one of our service offer.We take care of the following operations: Glass bead blasting Coating according to RAL colors electroplating Feuerverzinken cataphoretic coating sandblasting Dipping and spraying surface treatment The surface treatment of steel and steel parts has been one of our service offer. We take care of the following operations: Glass bead blasting Coating according to RAL colors electroplating Feuerverzinken cataphoretic coating sandblasting Dipping and sprayingWe take care of the following operations: Glass bead blasting Coating according to RAL colors electroplating Feuerverzinken cataphoretic coating sandblasting Dipping and spraying surface treatment The surface treatment of steel and steel parts has been one of our service offer. We take care of the following operations: Glass bead blasting Coating according to RAL colors electroplating Feuerverzinken cataphoretic coating sandblasting Dipping and spraying

Founded

1994

Employees

50 - 100

Certifications

Memmingen

Germany - 87700

ZN-Metall GmbH, based in Teising, was founded in 2016 by Andreas Nold and Christian Zerbin. In the meantime, the production area has been expanded to a total of approx. 3.000 qm with a second location in Heldenstein. Our modern machinery, consisting of innovative machining centers, meets the highest requirements for all production components. This wide range of production, our motivated team and many years of experience in metalworking make us your ideal partner when it comes to manufacturing all types of components — from prototypes to series production — from individual parts to small and large series In our profile processing processes, we specialize in non-ferrous alloys. In this way, we combine our strengths and guarantee proven quality — tailored to your individual requirements. As a metal processing company, we produce according to your drawings in the required quality at competitive prices. In doing so, we always pay attention to the best compromise between optimal resource conservation, economic efficiency and production processes. For us, effective work processes are an essential part of order processing. From the blank to the finished product, we deliver everything from a single source.

Founded

2016

Employees

20 - 50

Certifications

Teising

Germany - 84576

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We specialize in robot welding, laser cutting, bending, forming and deep drawing. We offer productions of parts and units for agriculture machines and equipment, trucks, trailers, machines for grains processing and storage, seeds cleaning and treatment, hydraulic power units, elevators and much more. Our clients are mostly from Bulgaria and from Europe, with many of them leaders in their industry, with a turnover of billions. CHROM AD was founded in 1965 in Silistra, Bulgaria as a result of separating the press division of the company for metal processing machines. Today we employ over 60 employees, with 5 000 sq.m. facilities and our services include: Robot welded constructions and components Laser cutted details Deep drawn and stamped parts

Founded

1965

Employees

50 - 100

Certifications

Silistra

Bulgaria - 7500

The company Sedlar doo specializes in high quality metal processing . Since 1993, we have been developing serial production and individual / custom made production according to specific customer requirements. The product range includes various metal products intended for use in construction and industry and households . We are able to respond to the most demanding projects of machining and manual processing of various materials. As part of machining, the company specializes in providing services of CNC milling and CNC turning, planned grinding and welding, CNC bending and sheet metal processing, fabrication of various metal structures and welding and polishing (partners Končar, Bechtel, Bertol, etc.). We place about two hundred products from our own range, such as angles, connecting plates, shelf supports, handrail supports, wire tensioners, screw goods, on the domestic market (wholesale distributors and retail chains Pevec, Građa, Uradi sam, etc.), but we also export through retail chains to regional market (Serbia and BiH) as well as in the EU. We also make locksmith constructions and substructures for interior and exterior furnishing (ShoeBeDo, Sposa wedding dresses, Miss Sixty). We are proud of our long-term cooperation with partners for the services of plasticization, galvanizing, galvanic processing, CNC laser sheet metal cutting.

Founded

1993

Employees

5 - 10

Certifications

Zagreb

Croatia - 10000

Hello, We are small company in Poland. So far, we have dealt with the preparation of cars for motorsports. This year, we purchased an automatic CNC lathe, which helps us prepare the cars, but it is also able to produce long series of parts because it is equipped with a bar feeder, picking up finished parts, two spindles and chip ejection. We also work closely with my friend's company, which has several automatic lathes and milling centers, which is why we are able to deliver comprehensively prepared parts. We have an Autodesk Fusion360 license. We have extensive experience in CNC machining, previously I worked in a large company dealing with the automation of the production process, which is why I took part in many large projects. From the idea, through design, parts production, assembly, commissioning, testing and installation at the customer's site. Maybe you have a need to make parts in perfect quality and at an attractive price? We will cooperate with pleasure. Please contact me if interested. www.jcnc pl Best regards

Founded

2019

Employees

< 5

Certifications

Olsztyn

Poland - 11-041

CFM Slovakia is a company founded in 2001 with production starting in 2002. The main production program is the manufacture of pressed components using pressing molds based on the drawing documentation sent by the customer. CFM Slovakia is a certified company according to IATF 16949:2016, EN ISO 9001:2016, EN ISO 14001:2016. ISO45001 We can also offer additional processes supporting the main production program, such as: • Secondary processes: riveting, inserting press nuts, thread cutting, screen printing, and various subassemblies • Surface treatments: in cooperation with our suppliers, we can provide electrolytic plating (Sn, Ni, Zn, etc.), powder coating, or cataphoresis • Assembly of electric motors Currently, CFM Slovakia is a supplier to several companies in the automotive and electrical industries.

Founded

2001

Employees

50 - 100

Certifications

Spišská Nová Ves

Slovakia - 05201

Founded

2015

Employees

10 - 20

Certifications

Wien

Austria - 1030

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge