Spray painting: find new suppliers on Techpilot

Discover specialized suppliers for spray painting on Techpilot. Our platform connects buyers with suppliers who use advanced painting technologies to achieve precise and high-quality surface coatings. Use the e-sourcing process to find the best suppliers.

498 suppliers for Spray painting

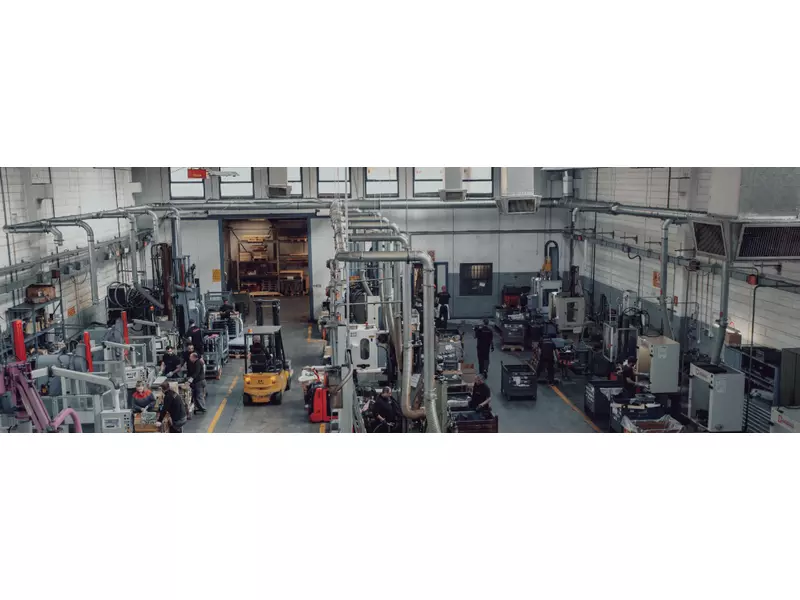

Manufacturing without limits: turning, milling, eroding, grinding, engraving, laser marking, ... benefit from our hughe and various collection of machines on four locations. Your stock stads by us - over 4.000 materials, alu, steel, stainless steel, titanium, tec. plastic, ceramic-glass, ... We twist for you - ask for impossibilities, our sheet metal forming realizes it. The word is colorful - our longterm experience of perfect surface finishes. Quality is no accident - our optimized quality management. Save paper, time and nerves - the best quality in the right place at the right time, all from a single source. We look forward to all questions, not only to inquiries. For more than 30 years Mühlbauer AG has been a proven partner for the provision of high quality precision components. It all started with a small lathe, from that we have developed into a globally operating company, which realizes all wishes concerning precision around the globe. From consulting, construction and prototype construction via manufacturing including surface finishing up to the installation of complex single components or whole machines, we have everything you will need for an optimum result.

Founded

2010

Employees

500 - 1000

Certifications

Roding

Germany - 93426

Founded

1983

Employees

50 - 100

Certifications

Goirle

Netherlands - 5015 HS

I have been working in the metal sector for around 15 years, where I have mine Completed an apprenticeship and in 2015 the foreman for mechanical engineering & Operational engineering completed. Starting in 2020 with metal decoration, fire pillars, etc. has A lively locksmith business has developed over the last three years. The professionally equipped one is located at the parents' farm workshop, where we are constantly developing and gladly yours Accept orders. “Challenge is motivation! ”

Founded

2020

Employees

< 5

Certifications

Reichersberg

Austria - 4973

Lapping, polishing, round, flat & centerless grinding, spherical radius processing as well as honing and drilling your ceramic, metal, glass,... -Parts in any batch size within a very short time at fair prices! As THE point of contact in the area of surface treatment, we are always happy to help you with highly qualified employees and the highest quality standards. 1840 Founding of A. SCHWEIZER GmbH 1874 Establishment of a glass grinding shop and start of development into a manufacturer of optical products At the end of the 1970s, the knowledge gained in high-precision surface processing was increasingly in demand among industrial companies in consumer electronics, automotive and medical technology, which were looking for problem solutions for the surface treatment of their parts (lapping, grinding and polishing hard materials and metals). 2003 First certification in accordance with DIN EN ISO 9001 2015 Founding of SCHWEIZER OFB GmbH as a 100% subsidiary of A. SCHWEIZER GmbH 2018 DIN EN ISO 9001:2015 certification A success that is due to our performance principles: Individual problem solving, flexibility and the best quality at a reasonable price and for every batch size!

Founded

Employees

20 - 50

Certifications

Forchheim

Germany - 91301

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

About us ... it is a small workshop in which ideas are built. I started in 2015, with steel constructions, and then gradually creating elements for decor, combining steel, wood, copper, brass and leather. Mainly we focus on interior design for home or public spaces, depending on what the customer needs, we provide consulting and together choose the best solutions. I invite you to visit us on our Facebook ADISBALAN.

Founded

2016

Employees

< 5

Certifications

Cluj Napoca

Romania - 404435

F.lli Carminati was founded in 1963 and specializes in broaching, shaping, and third-party grinding, as well as the construction of hydraulic pumps. Quality and research have positioned F.lli Carminati as one of the most important Italian companies in the sector. Large companies from the automotive, earth-moving machinery, commercial vehicle, arms industry, and agriculture sectors, as well as small businesses in various mechanical industries, rely on F.lli Carminati. The company processes large, medium, and small production runs, including single pieces of any profile, to specification or custom designs, and also works with challenging materials like stainless steel, DUPLEX, and INCONEL.

Founded

Employees

Certifications

Brescia

Italy - 25125

You want to focus even more on their core competencies? They want to keep their fixed costs and low investment requirements? We will help you by taking over a part of your production. The Rädisch GmbH is a specialist for sheet metal working processes of any complexity and is characterized by its extreme vertical integration. Our services range from individual production in small batch size on mass production to the development, manufacture and supply of complete assemblies, including eg of complex material handling systems. Our clients are mainly from the transport and vehicle industry, the machinery and plant engineering, material handling, retail and consumer goods industries. You will appreciate the simple, reliable co- working with Rädisch and rely on the uncompromising Quality of our products and solutions.

Founded

Employees

50 - 100

Certifications

Kirchheim/Teck

Germany - 73230

Construction: Development and design with various CAD / CAM systems, including Pro-/Engineer, Design Machining Processing: Sheet metal housing, chassis, front panels, mechanical components, weldments, turning and milling parts, special, pilot run and mass production Surface: Powder, enamel, screen printing, electroplating finishes, barrel finishing, polishing

Founded

1981

Employees

10 - 20

Certifications

Krailling

Germany - 82152

Cast-to-measure Fields of application: General engineering, machine tools, construction, drive and traffic engineering Molding technique: Hand molding (molding materials based on furan resin and bentonite) Material qualities: EN-GJL 200 - EN-GJL 350, EN-GJS 400-18 - EN-GJS 700-2 Lot size: Single pieces and small series Stckgewicht: 0.1 - 2500kg, custom demand Finishing / Surface treatment: Net power: prime, paint * Foreign power: electro galvanized, hot-dip galvanizing, polishing, powder coating, gum, heat treatment mech. Processing: CNC machining (contribution) Single production Models: Wood, metal, plastic and foam models http://www.eisenwerk-elterlein.de

Founded

1992

Employees

20 - 50

Certifications

Elterlein

Germany - 09481

The TIPS MTC family business is a reliable partner who can support you throughout the value chain. We offer development, and metal processing by cutting, punching, bending, and welding. According to your wishes, are items powder-coated or otherwise surface protected with the help of external contractors. Also, we can assemble everything, add additional purchased material by agreement, and pack and prepare for shipment to the desired address. These create a unique offer, so we see ourselves as a stable partner for contract manufacturing in the field of sheet metal assembly as well as for welding and electromechanical assemblies.

Founded

Employees

50 - 100

Certifications

Leskovec pri Krskem

Slovenia - 8273

Rugel is competent: We are responsible for perfect mechanical engineering. We will answer your questions. We solve your problems and wrap your orders quickly and safely. With us you will find for every aspect of modern engineering a contact person, the optimum technical equipment and quality-oriented team. They expect security - in quality, delivery and price. In Rugel you in every respect a precision landing.

Founded

1919

Employees

50 - 100

Certifications

Ravensburg

Germany - 88214

Severt the company was founded in 1964 as Rotary milling. In the sixties, the company was founded Vredener area and beyond as a manufacturer of known location made oil tanks. With the oil crisis of the early seventies declined Demand for heating oil tank so that a reorientation had to take place. The company became the Severt qualified welding company, the Contract manufacturing orders for the general machinery and Steel construction and in particular for carrying out the mining area. The Workpieces for the mining sector, which up in a series of 20 200 pieces are produced, reach a weight of up to 15 tons. They are by our clients as components for large coal mining installations. The end customers are Mining operations throughout the world, particularly in the U.S., Australia, China, etc. In addition, customized or edited to weld components for heavy-duty vehicles as well the plant. In the field of manufacturing of small parts are on robot systems Components for the automotive industry (Audi / VW, Ford, Mercedes, Opel) welded. For his own welding company developed the Company since the seventies Rotary Welding and Turnover positioner, which is also in the contract manufacturing customers successfully could be marketed. By positioner handling the heavy, bulky workpieces significantly facilitated, which next working time savings also reduce the risk of accidents with brings out. The high demand has led to very fast a broad, partially protected by patents Range and special solutions for Manual, automatic and robotic welding, and for other Areas of application. Our workpiece positioners and welding equipment with up to 50 tons. Capacity are to customers in Europe, China, India, Thailand, Egypt etc.been delivered. For over 20 years, the company is also Severt Robot system with extensive experience in the Manufacturing automation. We provide complete robotic workstations (all from one hand) which, alongside robots and positioners also Welding and flame-cutting equipment including the Safety technology includes. It is the customer-oriented individual problem solving of complex welding tasks priority. Besides a robot Demo Center and Departments of Construction and electrical engineering we can with a service team experienced technicians to fall back. Currently, about 400 workers at the company Severt, of whom 30 employees. Sales in 2007 amounted to EUR 50 million. In view of the growing Eastern European markets and the even more favorable wage situation in 1997 in Poland own production set up.The location in the southeast of Poland, near the border with Slovakia and Ukraine, gives us the Opportunity for good reliable staff recourse which the traditionally good contacts with eastern states have. Due to the extensive know-how in the Welding technology and the Company has the flexibility Severt company now has a solid reputation in your Business partners. This also shows the good response of customers in Robotics systems and Workpiece. This is for us a good basis for more activities on the common European market.

Founded

1964

Employees

200 - 500

Certifications

Vreden

Germany - 48691

We - that many individual personalities who provide their knowledge, their skills and their untiring zeal that your orders will be processed at 100 percent satisfaction. In 2006, our company has reorganized and now forms a strong unit that you can rely on. We are here to help in the areas of plastics technology, model making, mold making, prototyping and small-. The purpose usable materials ranging from aluminum and block material to plastic and wood. Flexibility, dedication and strict compliance with your objectives are with us not just tossed off phrases - but internalized principles. Therefore, we can also accept orders that need to be processed quickly. We support and advise our customers from idea to implementation to production.

Founded

2016

Employees

5 - 10

Certifications

Kerpen

Germany - 50170

The FME company is a supply firm for precision mechanics and medical technology. We offer everything concerned with precision mechanics, from series prototype to complete subassemblies ready to install.

Founded

1999

Employees

10 - 20

Certifications

Buchberg

Switzerland - 8454

Hennecke Feinblechtechnik GmbH

We process quickly and flexibly all plates using the latest technology and qualified personnel. Our services includes: - Laser cutting - Bending (folding) - Pressing (bolts, nuts) - Rivets - Welding (MIG, MAG, TIG), spot welding - Assembly - Machining - Surface treatment (own powder coating, custom edge rounding system f Alubauteile anodize galvanize,,, rays, pickle) - Construction Materials: - Stainless steels, spring steels - Mild steels - Aluminium - Galvanized sheet metal (electrolytic, sendzimir, hot-dip aluminized)

Founded

2006

Employees

20 - 50

Certifications

Buchholz

Germany - 53567

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Industrial Engineering: Realization of sheet metal parts and mechanical function ASSEMBLY Design office and sheet metal mechanics

Founded

2006

Employees

5 - 10

Certifications

LYON

France - 69005

Are all types of wet painting and sandblasting offered, just contact us

Founded

2010

Employees

< 5

Certifications

Herzberg (Elster)

Germany - 04916

Focus areas: • Processing of fine-grained structural steels up to S960QL • Welded structures up to 13 m in length • Large components up to 5 t component net weight • Mechanical processing up to 6,300 x 1500 x 1800 mm • Engineering services • Fixture construction with construction as a business area Certifications: • ISO 9001:2015 vehicle-connecting components) • KBA certified in accordance with German and international road traffic law • Welding approval for fine-grained structural steels up to S960QL including all process tests from S355 to S960 hand and robot • EN 15085 2 CL 1 (rail vehicles) • Manufacturer qualification in accordance with DIN 2303 Q2 BK1 • Welding certificate DIN 18800 7 class E • Welding certificate for welding steel structures up to EXC3 in accordance with EN 1090 2 • • Approval in accordance with ÖNORM EN ISO 3834 2

Founded

2000

Employees

100 - 200

Certifications

Thalgau

Austria - 5303

Innovative technology Made in Germany Since it was founded by Fritz Faudi in 1938, FAUDI has stood for innovative filtration and separation technology. Today, with its two product areas Coolant (coolant treatment) and Process (treatment of process fluids and gases), FAUDI GmbH guarantees high-quality plant engineering Made in Germany, which of course takes into account all important international approvals and certificates. FAUDI is committed to Germany as a location: At our headquarters in Stadtallendorf, central Hesse, we focus on project planning, engineering, construction, manufacturing, service, sales and marketing in order to provide our customers with the best solutions from a single source. Our representatives in all major regions of the world make it possible to serve our local customers promptly. We offer you genuine filtration solutions for a wide range of tasks. Our products and services help you comply with regulatory requirements and improve performance while reducing operating costs. Because when we talk about quality at FAUDI, it goes beyond the categories of durability and freedom from faults: “Total cost of ownership” (TCO) is an important benchmark for our engineers when it comes to project planning work. FAUDI uses its patented filter systems without filter aids. This results in less waste, which is not only economical but also serves to protect the environment and our planet. The plant processes are fully automated and therefore support and simplify work processes. The exclusive use of high-quality components in product design are key reasons why FAUDI systems are so durable and safe. We're here to help you achieve your goals.

Founded

1938

Employees

50 - 100

Certifications

Stadtallendorf

Germany - 35260

Jeners Druckgusstechnik GmbH

Company: Jeners diecast GmbH Headquarters: Kruppstr. 51, 42489 Wülfrath Phone: 0049 (0) 2058 / 7785-0 Fax: 0049 (0) 2058 / 7785-99 E-mail: info@jeners.com Internet: www.jeners.com Legal form: limited liability company (GmbH) Year of establishment: 1925 Commercial register: HRB 13204 Annual turnover (depending on the base material): Warning: influenced by the material base Production area: 12,000 m² Number of Employees: 90 R & D effort: 3, QM: 5 Product / Service CAD construction Prototyping in ABS with dimension STS 768 Molds and tooling Zinc die casting manufacturing Machining Assembly production IMDS application is standard Declarations of Conformity (REACH, RoHS, etc.) are standard Hardware 26 die casting hot chamber machines 20-315 tons clamping force Hydraulic Presses (some dialogue) CNC Machining Center (4 axes) Blasting machines Vibratory Finishing Machines Threaded machines Assembly machines Special machines Surface machining With certified partners: galvanic surfaces Paintwork Powder coating KTL coating Special coatings Certification: DIN EN ISO 9001/2008

Founded

1925

Employees

50 - 100

Certifications

Wülfrath

Germany - 42489

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge