Tubes and pipes - pipe machining: find new suppliers

Discover specialized suppliers for tube and pipe machining on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to manufacture precise tube and pipe fittings. Use the e-sourcing process to find the best suppliers.

574 suppliers for Tubes and pipes pipe machining

Metal processing 6 people Welding Pipe bending, punching

Founded

1984

Employees

5 - 10

Certifications

Werther

Germany - 33824

Started in 2022 as a small engineering service provider, RiSo also manufactures special machines in the field of suction technology with hydraulics, pneumatics and control technology. Thanks to our partner network, we are not only able to offer special machines and welded constructions, but also large quantities of precision steel tubes as well as stamped, bent, laser and milled parts. Pre-assembly, component assembly, extended workbench - anything is possible!

Founded

2023

Employees

5 - 10

Certifications

Leimersheim

Germany - 76774

Cold deformation of tubes & profiles including their processing Tube and profile bending / rolling

Founded

1951

Employees

20 - 50

Certifications

Birmensdorf

Switzerland - 8903

Manufacturing program Demolition attachments, Demolition equipments: * Demolition and sorting grab * Pulverizer - Fix pulverizer - Rotating pulverizer * Concrete crusher, Concrete shear, Multiprocessor * Crusher Jaws - HCM-M - HCM-C - HCM-S Our brand is: Quality, power, reliability, price-performance ratio. Our goal is: Our customers are 100% satisfied with our products and with us. Demolition equipments, demolition attachments Demolition and Sorting Grabs The new generation of demolition and sorting Grabs HCG was created for compact excavators. HC grabs can be very effective for: Demolition projects, Sorting from scrap and waste, Handling. Thereby a significant reduction of the wast disposal costs is achieved. Pulverizer, fix and rotating The new generation of pulverisers, HCP and HCP-R have been developed for the primary and the secundary demolition. The HC-Pulverisers can be very effective, and can be used with absolute safety for demolition of constructions, brickwork, concrete plates, concrete structures and recycling activities Concrete Crushers Our Multiprocessors, new generation of Concrete Crushers, have been designed and developed for universal use in heavy demolition and recycling works. These are designated for 15 to 45 tons excavators. The Concrete cruschers can work very effective and trouble-free in primary and secondary demolition.

Founded

1996

Employees

5 - 10

Certifications

Schemmerhofen

Germany - 88433

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

- Development / design of devices / gauges -Mechanical manufacturing on 3-5 axis machining centers -Qualification with measurement report generation on CNC coordinate measuring machines All from one hand

Founded

2000

Employees

20 - 50

Certifications

Oppenweiler

Germany - 71570

We are a CNC contract manufacturing company with production facilities in Bursa - Turkey and a branch office in Darmstadt, Germany. Our fleet consists of CNC turning and milling machines as well as welding equipment. Our services include CNC subcontracting and welding work according to DIN standards.

Founded

Employees

< 5

Certifications

Darmstadt

Germany - 64295

Founded

Employees

20 - 50

Certifications

Kardzhali

Bulgaria - 6600

Your experts for welding technology from Limeshain Exceptional services and quality are always the result of thorough planning. Our work does not start in production, but always begins with the first customer discussion. We manufacture workpieces from individual components to complex welded assemblies. Our experienced welders are all tested according to DIN EN ISO 9606. Thus we produce qualitative MIG, MAG and TIG works Welding is our vocation Professional welding Where you need us! Your order is our priority! Whether on site in your company or in our production hall. Our welders are tested according to DIN EN ISO 9606-1.

Founded

2018

Employees

5 - 10

Certifications

Limeshain

Germany - 63694

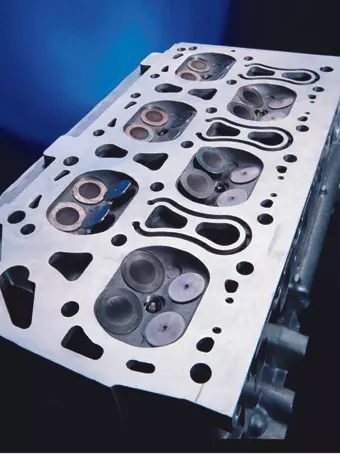

Engineering services - automotive industry (OEMs and suppliers) Parts are manufactured and Versuchsmusterbau for prototypes (individual productions and mini-series), Machining, Welding metal machining, sheet metal forming, tube machining, quality assurance / fine measuring space, turning, bending, milling, welding Region of Saxony (09120) Chemnitz Machined materials are mainly aluminum, aluminum alloy, steel, stainless steel, plastic. For range of parts including car parts, engine parts, engine components, systems and equipment, test set-ups. Examples are manufacturing cylinder heads, pistons, crankcase, crankshafts, camshafts and components for mechanical engineering and plant construction.

Founded

1983

Employees

> 1000

Certifications

Chemnitz

Germany - 09120

We are a trading and service company for hydraulic components, hydraulic power units, which find its use in machines and systems. Includes Our hydraulic supply, hydraulic components (eg small units, AC motors, gear pumps, manual control valves, pressure relief valves, hydraulic tubes, hydraulic couplings, hydraulic motor-pump units, pressure gauges, hydraulic fittings, hydraulic hoses) and much more. The complete hydraulic goods, we refer exclusively by renowned hydraulic manufacturers that can boast decades of experience in the production and manufacturing of hydraulic products for OEMs and machine builders. Here is an overview: - Repair of hydraulic power units to 400l at the factory. - Repair of hydraulic power units on site. - Repair translated, assemble and test of hydraulic blocks. - Repair of hydraulic presses Pretended pipe bending and assembly according to your - - Exchange of bladder bladder accumulators - Harnessing of hose lines - Tubing change - Mobile Oil Filtration - Particle measurement - Fluid removal + analysis according to VDA 19 orISO 16232 - Filter change - Filtransionskonzepte for your systems in close cooperation with a fürenden filter Manufacturers - Filter design - Hydraulic presses Safety verification in accordance with BGI 724 (old BGR253 and VBG7n5.2) incl Nachlaufwegmessung - Repairs and overhauls - Modernization of old plants - Spare parts Service

Founded

2007

Employees

< 5

Certifications

Plochingen

Germany - 73207

CORPORATE DEVELOPMENT WALTER HENRICH GMBH - the partner for development and production of formed and machined parts made of pipe and solid material. Since its founding in 1959, the company has posted strong commitment by all employees and through continuous innovation and investment in efficient production process, a successful company history. In the development and implementation of new technologies and thanks to excellent client service by our dedicated team, we have set ourselves the highest level of customer satisfaction as a task. The aim of the corporate philosophy of WALTER HENRICH GMBH is specializing in technically demanding products. This orientation is with the use of all of our know-how to benefit our customers and partners.

Founded

1959

Employees

100 - 200

Certifications

Daaden

Germany - 57567

We are a reliable partner and a young, powerful company, with experienced professionals and a modern workshop equipment for welding, steel construction and special designs. Our master craftsmen allowed to present himself for the almost entire range of metal processing in steel construction and locksmith craft. It has always been our endeavor to maintain a good connection to our customers maintain or extend. We have a long experience in the field of industrial assembly and welding of all kinds Custom made stainless steel and aluminum applications complete the product range. We manufacture to your specifications, drawings as well as our own designs. A good price / performance ratio, the observance of deadlines and technical requirements are a matter of course for us. Furthermore, we offer a high degree of flexibility. Give us your trust and we will do our best.

Founded

1994

Employees

5 - 10

Certifications

Grevenbroich

Germany - 41515

Fe&E GmbH

For manufacturers, it's about time and reliability. All parts required for a production chain must always be available in sufficient numbers. If they are not, in the worst case, the tapes will stop. We'll help you make sure it never happens. By manufacturing and processing metal accessories for you that fit perfectly and impress with their quality. From laser-cut prototypes to complete lacquered series, we offer you exactly what you need when it comes to metal. We draw, laser, bend, weld and paint for you, while still adding a layer of dedication to what we do. Convince yourself of our work now! You gain a reliable production partner for the future. Trumpf Laser + Automation If we set up our laser cutting system with the required CAD data, you will receive custom-cut metal parts in the desired material thickness in the shortest possible time. We produce hardly any waste and therefore act particularly efficiently and in a resource-saving manner, which is reflected in low costs for you. Special shapes or recesses are no problem for the cutting system. Trumpf press brake If you have special requirements for your metal parts in terms of shape, we will process the desired material for you until it has exactly the properties you need. This also includes precise bending, in which we gently and consistently produce precise curves or even bend solid (precious) metals with the necessary pressing force. Fronius welding machine To weld around material or securely fix two composite materials, we use the proven WIG and WIG/MAG welding processes. To this end, we have highly trained personnel in our team who work precisely and quickly and entirely according to your specifications for the finished part. Trumpf marking systems High-speed marking

Founded

2021

Employees

5 - 10

Certifications

Wurmannsquick

Germany - 84329

Our company has already dealt for decades with the technique of tube bending. Through numerous different tasks, we were able in this field gather knowledge and experience, which we can invest in the quality of our products and service for our customers and want. In the area of tube bending we can offer the following products and services: * CNC tube bending technology to 10 modern CNC bending machines with a minimum diameter of 2 mm and a maximum diameter of 65mm * Surveying and Documentation of tube geometries by two modern 3D measuring machines * Pipe end machining and forming

Founded

1983

Employees

20 - 50

Certifications

Göppingen

Germany - 73037

Promming d.o.o.

The “PROMMING Čakovec” company was founded in 1990, and has developed to one of the leading manufacturers of store and warehouse equipment, as well as office furnishing in the domestic market. The company currently has a workforce of 120 people, out of which a 100 people work in the production process.Production program of the company covers a very wide area - equipment for shops and warehouses of all the capacity and purpose, and interior equipment. The metal processing line covers a wide range of production processes in metal fabrication: 1.the sheet metal slit is done on the automatic line for both the longitudinal and lateral slit which is dimensionally adapted to the needs of further processing, whether it be profile fabrication for warehouse systems or equipment positioning for stores 2.the cutting out of position layout is done on CNC machinery and on the laser cutter; this technology represents the very top of metal processing and enables us to manufacture various shapes and forms, with maximum production flexibility concerning dimensions and quality service 3.the sheet metal is bent on the whole series of machines adapted so we can cover all market needs – from individual positioning to serial production: the line for continuous bending of profiles represents our base technology, and is used for: manufacturing of profiles for all warehouse systems; those lines continuously produce profiles cutting them to the appropriate length, specified by the customer manufacturing of shelves and trade system equipment backgrounds, which has high rate of production, while still staying flexible on the level of each product bending on the sheet metal benders is used in cases of small series with high flexibility in position measurement bending on the CNC bending machine wire products are produced on the CNC machine the welding of positions is done both by welding robots and manually: the welding robots are used for position manufacture of our warehouse program, meaning all positions which are produced in large series; this technology ensures production of high quality identical positions manual welding is done by qualified welders with longtime experience in manufacturing warehouse and store equipment The final position processing is done in our facility by electrostatic plastic or Zink coating; both processes are done on separate lines taking care of both the high quality of final processing and ecological ethics: the plastic coating of positions is done on two separate line which enables a capacity of manufacture; the process of plastic coating consists of chemical treatment and preparation of the positions for the painting which is done by robot, after which they are baked in flow ovens; the paint is applied in special booths which enable color switching within 10 minutes, further ensuring a broad range of colors of our products; the heating of the lines is done by warm air heated by an oven fueled by biomass; the bake oven uses thermo oil as a medium, which is a new technology developed for our purposes; this technology ensures the energy for all our processes – from the plastic coating lines

Founded

Employees

Certifications

Cakovec

Croatia - HR-40000

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Company Stainless Steel Haese is a metal processing plant, for the materials of stainless steel, Aluminum, brass and copper. We manufacture for the boating industry (the yacht sector), since about 3 years Megayacht area (quality products) and in the private sector in the construction industry to measure. The company was founded on 01.11.1990 by Frank Haese in Wolter village. It was quickly recognized that firms are sought, which also realize custom-made and individual customer requirements for mega yachts and the private sector. In the field of surface treatment, we can V4A stainless steel and other metals grinding, polishing, polishing and mirror E-polish.

Founded

1990

Employees

10 - 20

Certifications

Woltersdorf

Germany - 15569

Firm has activity at repair of tractors Zetor and manufacturing of welded products as pallets,containers,others welded construction according to orders of customers. Firm provides a renovation a disc clutches,brake shoes by gluing of linings.

Founded

1996

Employees

10 - 20

Certifications

Nitra

Slovakia - 94901

The Knupfer Metal Processing GmbH is a sheet-processing supplier for the machinery and special machinery for air conditioning, ventilation and suction technology, clean room technology and the automotive industry and has worked for over 50 years. We manufacture sheet metal parts, machine covers, protective covers, enclosures, machine bases, machine body and complete assemblies from lot size 1 steel, stainless steel and aluminum. Our high-tech production in-house include: Laser Cutting (Automated high-bay warehouse) The following material can be cut: steel up to 25.0 mm, stainless steel up to 20.0 mm (oxide-free), aluminum up to 12.0 mm material thickness. The max. Machining size is 3000 mm x 1500 mm. All three stocking systems are connected to an automatic high bay warehouse with 220 storage bins (3 tonnes storage capacity). We are thus able to cut during the night shift without staff. Water jet cutting 5-axis machining of steel up to approx80 mm, stainless steel up to 80 mm, aluminum up to 100 mm - other materials such foam, plexiglass, plastics, glass, stone, sealing material, composite materials, wood, etc. possible. The max. Machining size is 3600 mm x 2000 mm Bending Pressing force of the CNC press brakes: 1 x 320t, 200t x 1, 1 x 36t ACB angle sensor available, 3-point bending is included as standard, Folding Machine in use Nibbling and punching Steel up to 6.0 mm, stainless steel up to 4.0 mm, aluminum up to 6.0 mm The installation of ventilation gills, beading, perforated grids, rows etc. is easily possible Welding (Manually or with robots) MIG / MAG and TIG, spot and stud welding (threaded bolts and sleeves), welding robot with rotating and tilting table for components up to 5000kg unit weight. These saws, laps, mech. Machining (milling, turning, drilling, threading), production of flange rings according to DIN 24154 and angle rings to DIN 24155, as well as special rings and segments and paint the assembly and completion according to the surface treatment (powder coating, galvanizing...).

Founded

1959

Employees

50 - 100

Certifications

Hohenstein - Eglingen

Germany - 72531

The TAWESCO is leading producer of tools, metals stampings, weldments mainly for the automotive industry but also trucks, agriculture and forestry machinery, mostly heavy weldments including surface treatment and welding fixtures. Key figures: • All in one solution under one roof (DESIGN – TOOLING – STAMPING – WELDING) • Turnover about 78 mil. EUR in 2019 • 950 employees • Production area about 50 000 sqm in Koprivnice near Ostrava city • Tradition since 1850 as TATRA Trucks production • Quality management: EN ISO 9001:2015, IATF 16949:2016, VDA 6.4., ISO 14001:2015, ISO 3834-2 • CAD-CAM Capaility: AutoCad, Catia V5, Autodesk Inventor, IDEAS, AutoForm Tawesco competitive advantage: "All under one roof ": stamping + welding + tooling + design Stamping: • Metal and aluminium stampings for automotive industry up to 50 kg • Mechanical, eccentric, progressive and transfer presses up to 2000 kg • Press breaks up to 8 m Welding: • Weldments for automotive - spot and laser welding • Heavy weldments for trucks, agriculture, forestry and municipal machines • Robot, automatic, semi-automatic and manual welding • 2D/3D laser cutting Tooling and design: • Welding and machining jigs up to 15 m • Tools for forming, bending and perforation of steel sheets up to 50 T • Milling centres, drilling and grinding machines • Try-out hydraulic presses 1250 T and 2500 T Quality management: EN ISO 9001, IATF 16949, VDA 6.4., ISO 14001, ISO 3834-2. References: 1. John Deere, Kemper, CLAAS, KION- Linde Material Handling, Fenwick 2. TATRA Trucks, IVECO 3. SKODA Auto, Audi, VW, Bentley, Daimler 4. GESTAMP, SNOP, TIBERINA

Founded

1995

Employees

500 - 1000

Certifications

Koprivnice

Czech Republic - 74221

The company STN Neugersdorf was founded in 2007. Meanwhile five people are employed. Our main task refers to the precision welding using the TIG process of stainless steel, aluminum and aluminum-magnesium alloys, cast iron, copper, brass, titanium and chromium-nickel. In addition, we weld assemblies according to customer request and requirement in the MIG and MAG welding using the latest processor-controlled and water-cooled, double-pulsed Rehm and Cloos systems. Furthermore, we are able to solder galvanized steel sheets also MIG and TIG, as the brazing of hard metals and cast iron with special silver solders. Orders in resistance spot welding and pressure welding bolts we can meet on time and in large numbers. Our factory is checked for all welding according to DIN EN 287-1 and DIN EN ISO 9606-02. In addition, we also offer the Salzbadbrünieren of steel parts for the tool and mechanical engineering. For inquiries, as well as sample production we are at any time. Please visit us on the Internet at: www.schweisstechnik-neugersdorf.de You will find numerous product and production examples, and our reference.

Founded

2007

Employees

5 - 10

Certifications

Neugersdorf

Germany - 02727

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge