Turning: receive an avg. of 7 offers per request

Find specialized suppliers for turning on Techpilot. Our platform offers access to suppliers who use advanced turning technologies to manufacture precise and customized parts. Benefit from comprehensive market transparency and optimize your supplier selection.

4617 suppliers for Turning

Welcome to a family company CNC Tratnik d.o.o. where precision meets innovation. Our state-of-the-art CNC turning technology and experienced team ensure the highest quality of customized parts for a variety of industries. From prototype to production, we strive to exceed your expectations with our efficient turnaround times and competitive pricing. Let us help bring your ideas to life with precision, speed, and quality.

Founded

2000

Employees

10 - 20

Certifications

Muta

Slovenia - 2366

The "Maritza M" company is established in 1991. Initially, it imported, installed and maintained only lifts with foreign origin. Nowadays, certified under ISO 9001:2008, we design, produce, deliver, install and maintain all kinds of lifting systems (with 25-month warranty period) that add elegance to your buildings. Decorated in "Pret A Porte“ style and enriched with numerous accessories from France, Italy and Spain, our lifts help the architects in their mission to create beautiful buildings. Our technical equipment allows us to produce spare parts even for all the old lifts according to the technical documentation. And for the people that are looking for a change we offer renovation of the car or replacing the entire lift.

Founded

1992

Employees

20 - 50

Certifications

Sofia

Bulgaria - 1528

Metal and steel, sheet metal work flexibly, machining, surface finishing, assembly, logistics in two plants in Germany and Luxembourg. Individual consultations In the realization of your ideas, there is a qualified staff to the side, which is used flexibly to your wishes and ideas. Advise project-specific basis and we will inform you via the respective optimum materials and processing techniques for the ultimate in durability and cost of the final products. Functional constructions Equipped with the latest CAD systems, take over our trained professionals either your design data to adapt to the individual manufacturing steps or plan according to your individual requirements, always with respect to the functional and aesthetic aspects in the subsequent application. High quality productions Our production services range from the technically competent implementation of various individual orders up to industrial scale production.This construction can be produced up to 10 tons of dead weight. The modern machinery and qualified staff at all levels of production are the guarantee for a correct processing of the selected materials. The use of inert gas welding process MIG / MAG and TIG, manual and robotic systems, are for us as naturally as the use of various painting and finishing techniques. An example of our performance are the cutting-edge laser cutting machines for sheet steel up to 25 mm, stainless steel sheets up to 15 mm free of oxide or aluminum sheets up to 10 mm. Even galvanized sheets and titanium, are hereby processed. With a cutting area of 3,000 x 1,500 mm, a cutting accuracy of + / - 0.1 mm and a repeatability of 0.05 mm maximum precision is assured, from the first to the last position. An elaborate post-processing of parts is thus necessary only in a few exceptional cases. Powerful processing Flashings up to a length of 4,250 mm can be processed on our 6-axis CNC press brakes. For this purpose, a pressing force of 2,250 kN. Cuts miters or be executed also CNC controlled using advanced saws millimeter. Further processing is completed by the add in the common welding processes MIG, MAG and TIG, what are we nebem manual welding stations 2 welding robots available. As of August 2012, we are expanding here in the area of laser welding / laser hybrid welding up to 4,000 mm x 2,000 mm with 6 kW fiber laser. Of course, we also carry out the mechanical processing services according to your wishes. Approvals in accordance with DIN 18800, DIN 18808, DIN 15018 and DIN 4099 are available for this purpose. In our newly established and continually expanding range of machining, we have a DOOSAN PUMA 2100M lathe, as well as a Mazak CNC machining center. Another sector in our company is the architecture of the area. Here we offer the complete range of windows and doors, fire doors, mullion-transom facades and metal cladding of and for buildings. The steel construction completes our range of services. With stairs, railings, balcony systems, connecting bridges, canopies, etc., we cover here from another area in the metal and steel.

Founded

1991

Employees

100 - 200

Certifications

Grevenmacher

Luxembourg - 6776

We are a small family manufacturing company that has specialized in the realization of any claims or demands of our clients in the field of mechanical engineering. Our core business is Cnc milling and we can offer you milling range up to 1250x600x650.(5 machines) Production site is located in Samobor, CROATIA near capital Zagreb,2 km form highways A1,A3,A4. Offer: -Milling -Form milling -Engraver milling -Spark erosion wire cutting -Spark erosion and Etching -Injection moulding -Stamped and sheet metal formed parts

Founded

1980

Employees

5 - 10

Certifications

Sveta Nedelja

Croatia - 10431

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Production service aspiring to perfection We are happy to take on highly complex production assignments for our customers and to elaborate quality solutions which aspire to achieve perfection. Every division of ZELTWANGER Maschinenbau GmbH takes this ambitious aspiration as the quality standard for its day-to-day work. But the most important factor in our company is its workforce: a rock-solid, totally reliable team of men and women whose commitment and enthusiasm for their work and the manufacture of top quality products spurs them on to achieve ambitious standards and ever higher performance with each passing day. It is this motivation which has created scope for our extreme work time flexibility. We produce in two to three shifts six days a week. Our entire technical innovative drive and resolute quality orientation are channelled into the production of challenging prototypes, complete assemblies, small-scale series and individual components. Production processes High-tech is the standard at ZELTWANGER Maschinenbau GmbH. This is reflected in our highly qualified team of specialists, in our logistical division of labour, and in our use of the very latest production processes and technologies. Our machining centres and lines are programmed and controlled over a central network. Innovative 3D programming systems permit even the most complex workpiece contours to be machined. In the metal cutting field, our CNC milling centres use 5-sided machining techniques. All our lathes are fitted with power tools and with a C and Y axis. Our products are characterized by optimum grinding results with millimetre range precision for the ultimate in productivity. With our high-precision spark erosion cutting machines we also have the capability to manufacture custom-produced parts and small-scale series in-house. Materials - broad selection, quick availability Alongside our extensive ultra-modern machine outfit, we also benefit from a wide range of stocked materials in our automatic high-bay warehouse. These include all steel, titanium, stainless steel and high-strength alloys as well as all popularly requested aluminium alloys. We also offer a raw material procurement and storage service to customer order.

Founded

1982

Employees

100 - 200

Certifications

Tübingen

Germany - 72072

Founded

2001

Employees

20 - 50

Certifications

Untersiggenthal

Switzerland - 5417

ZVIREX, Tržič, d.o.o. is a private family-owned company, which was founded in 1991 and based in Zvirče in the municipality of Tržič. In 1998 the company relocated to new commercial premises in the industrial zone at Loka near Tržič, which is today home to the company headquarters.

Founded

1991

Employees

5 - 10

Certifications

Tržič

Slovenia - 4290

Our company was born in January 1986 under the name of MECBAR Snc Founder Teodoro Bartolini, who after over fifteen years of experience in the field Of mechanics, as an entrepreneur, decides to collaborate with his children. The intention is to specialize in the construction of precision equipment for multiple fields Of application, today has been achieved thanks to a gradual development in the no time Never overlook the quality standard that has always characterized us. The equipment of our production is built entirely within Our company using our ever-updating machinery under the look Technological development and this constant development has allowed us to specialize in the machining Milling of hardened materials also over 62 HRC of hardness, in machining of Drilling, threading and milling of hard metal, also over 1600 Vickers, with mole and Polycrystalline diamond cutters and also tempered and non-tempered materials, with Dimensional and geometric precisions less than 0.005 mm obtaining a degree of finishing With a Ra of between 0.3-0.7.

Founded

2001

Employees

10 - 20

Certifications

Nova Milanese (Monza Brianza)

Italy - 20834

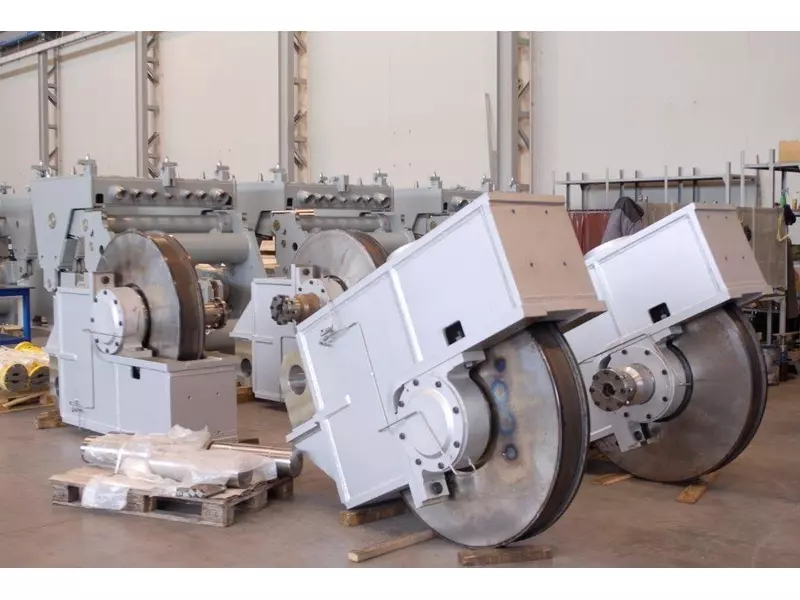

Easymec S.r.l. is a small-medium Company, having factory and headquarters in Osoppo, 18 km north of Udine city, on the north-east region of Italy and close to Austria and Slovenia borders. EasyMec S.r.l. is specialized on construction, welding and mechanical machining of medium and large steel components, based on Customer’s design and technical requirements. High value-added operations are: milling/boring, sanding and spray painting , wear and abrasion resistant surface coatings (by MIG technology) Thanks to its qualified personnel the Company is also available to offer on site many services of maintenance, revision, revamping, commissioning and inspection of industrial machines; as well its’s possible to request also equipment mounting & assembling services, including electrical hydraulic and pneumatic systems.

Founded

2006

Employees

20 - 50

Certifications

Osoppo (Udine)

Italy - 33010

Workings: turning milling correction induction hardening Components: Sleeve Pin joint shell Flange Spacer

Founded

1992

Employees

10 - 20

Certifications

Rossano Veneto

Italy - 36028

With foresight we see the development of the markets and your needs in the field of milling technology. As a result, we have repositioned ourselves, innovatively-efficiently positioned and made investments that prepare us for future requirements and provide you with intelligent and high-quality solutions. We s

Founded

1995

Employees

5 - 10

Certifications

Bissingen/Teck

Germany - 73266

The Company OFFICINA TOGNI SRL was established in 1995 by the corporate transformation of OFFICINA WALTER TOGNI, company founded in 1968. For over 50 years our company has been specializing in CNC and traditional turning and milling . Decades of experience, a developed production capacity and a highly specialized workforce allow us to carry out high-precision machining also on critical and complex components. We are approved suppliers of leading companies of different industries: Renewable Sources, Oil and Gas, Machinery Manufacturers (Presses, Packaging, Plastic, Pharmaceutical, Food and Beverage Industry) Design and Furniture. We supply both to Small and Medium Enterprises and to Multinational Companies, also as exporters to different EU countries. Our strengths are versatility, production flexibility, experience, accuracy of processing, timely management of urgencies.

Founded

1968

Employees

5 - 10

Certifications

Milano

Italy - 20037

Ypsotec is one of the leading manufacturers of precision and complex components requiring high quality surface finishing – or laser welding technology. We have long-standing partnerships with numerous leading medical device companies. We are located in Grenchen (CH) and Tabor (CZ) Turned and Milled parts All our Ypsotec`s turned and milled parts are manufactured to the highest precision standards. Permanent investments in machinery and regular training of our experienced and professional employees are realized to meet our customer’s requirements. Our flexibility is reflected in the variety of materials used in production: We process light and non-ferrous metals, steels as well as titanium and PEEK. Laser Technology Ypsotec provides high precision laser welding competencies utilizing the most modern JAG laser technology and methodology. Our experienced professional personnel bring new cost effective solutions to the field of laser marking, laser engraving in addition to laser welding. We offer: - Turning - Milling - Laserwelding - Assembling of Subassemblies - Feasabiliti check

Founded

1916

Employees

100 - 200

Certifications

Grenchen

Switzerland - 2540

We are a company from Split, Croatia, and our core business was engine parts refurbishment. Now, we have started to manufacture parts on a CNC lathe, and would like to further expand our new area of business. If this sounds interesting to you, please contact us for more detail!

Founded

Employees

< 5

Certifications

Kastel Stari

Croatia - 21216

The Bochum firm Link & Tepel GmbH is a competent partner in the field of manufacturing of complex turning and milling parts. Similarly, we are able our quality on our 3D coordinate measuring machine of the type Zeiss Accura to prove in fully air-conditioned measuring room. Customizable solutions often toughest schedules wishes are carried out by the Link & Tepel GmbH for various industries, such as general engineering, power generation and tooling. Here, terms such as quality, flexibility and punctuality Dont phrases, but are among the pillars of our corporate philosophy.

Founded

1907

Employees

5 - 10

Certifications

Bochum

Germany - 44805

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Production of hydr. and mech. Fixtures for machining centers. Production of cpl. Collet chucks, special chucks and collets. Like production of special clamping and gripping jaws, as well as special tool holders Gen. mech. Processing of type-dependent parts.

Founded

1986

Employees

5 - 10

Certifications

St. Ingbert - Hassel

Germany - 66386

Our core competence lies in the machining and the design and implementation of special bodies or custom Weldments and production outsourcing customers. If you wish, we will even cover the procurement of materials, surface treatments or any other manufacturing processes for you. Our Services Turning CNC and Conventional Milling CNC and Conventional Keyway poking Plane Mechanical Engineering Welding (MIG / MAG, TIG, TIG, electrodes) Edges, warping, burning Painting Special arrangements 4-axis controlled boring machine OERLIKON Machining Center MAZAK (with tilting table) 5-axis machining center REIDEN BFR 23 (integrated rotary table and A + B axis) Turning to 8000 mm tip diameter and 1500 mm passage

Founded

1946

Employees

10 - 20

Certifications

Rümlingen

Switzerland - 4444

Founded

2001

Employees

5 - 10

Certifications

Rödermark

Germany - 63322

Numberger GmbH

Numberger Technologies is a medium-sized family company that has more than 50 years of experience in all relevant industries and areas. A part of our core competence lies in the areas of sewage treatment plants, pipeline, plant and mechanical engineering. We have also continued to specialize in food technology components, special designs, conveyor technology, individual part production and prototype construction. We know the challenges our customers face and work together to find the best possible solution. Our quality standards, our experienced and service-conscious specialist staff as well as the modern production facility are the guarantee for our delivery reliability and precision. Personal support, tailor-made solutions and first-class service tailored entirely to your individual needs - that is NUMBERGER Technologies. Our motto is: "A company can only survive if its learning pace is greater than the rate of change in its environment. "

Founded

1928

Employees

20 - 50

Certifications

St. Wolfgang

Germany - 84427

MODYMA s.r.o.

We are a family company dealing with CNC machining since 2010. Throughout our existence, we make sure that the high quality of production, surfaces and materials is itself a good advertisement. Thanks to this, we have customers, mostly foreign, who have been working with us for years. We value these partnership relationships very much, because it is thanks to them that we have the opportunity to develop, learn new things and take on more and more challenges.

Founded

2015

Employees

20 - 50

Certifications

Jaroměř 1

Czech Republic - 55101

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge