Deep drawing: receive an avg. of 7 offers per request

Discover specialized suppliers for deep drawing on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to create high-quality deep-drawn products. Use the e-sourcing process to find suitable suppliers in real time.

421 suppliers for Deep drawing

- Tool with its own design for the production of progressive and Forming tools - Profile sanding to 2.000 mm - 2D/3D-Laserschneiden - Auto parts production on eccentric and hydraulic presses 4-630 to with subsequent installation to complete. Assemblies including cathodic surface. - Single orders with customer supplied materials and tools - Milling of aluminum and steel parts 3 to 5-axis machining centers (Prototypes, small and medium series) - Compl. Modules f bus air-conditioning systems, for example, discharge housing to 2 m in length, Refrigerant collector

Founded

1928

Employees

50 - 100

Certifications

Landsberg

Germany - 86899

Establishment in 1874, Today, innovative Blechbearbeitungszentrum: Engineering Toolmaking Forming System supplier diecast Joining / welding Surface Technology Assembly / assemblies Logistics Flat, process-oriented organization, own large machinery 1 August 2010: Move to the new Büro-/Produktionsstätte: CO2-neutral building approximately 60 employees Customers at home and abroad

Founded

2006

Employees

50 - 100

Certifications

Netstal

Switzerland - 8754

We as schoolboys stamping and forming GmbH + Co.KG working since 1846 as a supplier of metal processing. Finished and supply parts from various materials for industry and trade. Our product range extends from single pieces to medium series. Our manufacturing capabilities include: • CNC manufacturing to ᴓ 600 mm • high volume turned parts up to 24 mm ᴓ • own tool • Die cutting to 110 to • Welding TIG / MAG / Alu • individual trolley systems • Special Fittings We produce all kinds of fittings, stamping parts, stamping parts tool Falling or inlays in several steps. Also done in-house milling and turning as well as tool for the subsequent series production. We are happy to provide advice and practical help and guide you from the development to the finished part.

Founded

Employees

< 5

Certifications

Magstadt

Germany - 71106

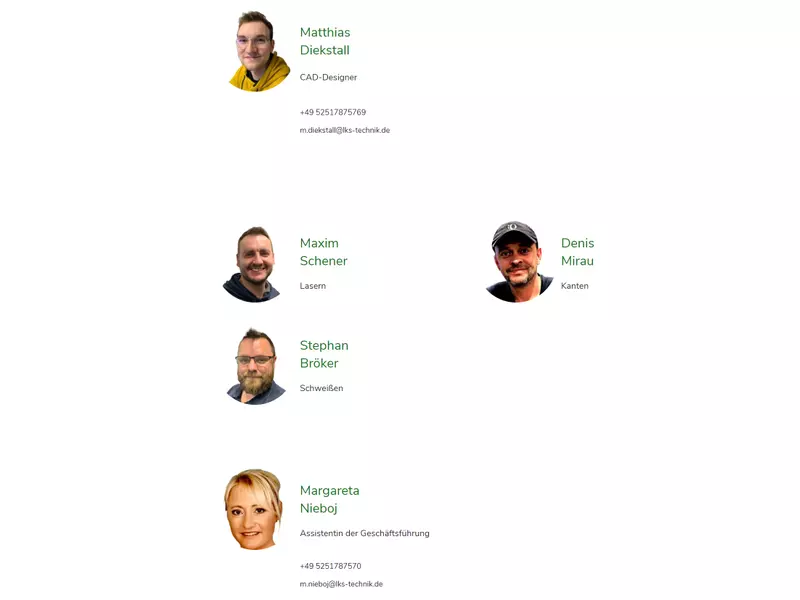

Welcome to our young and dynamic company in Paderborn! We started 2019 with a case of beer and an idea and have now developed into a successful company with 14 dedicated employees. We owe this in particular to our fast and efficient single-part and small series production in the areas of laser cutting, edging and welding. Our passion for precision and quality has made us a reliable partner for many companies in the region. We offer you tailor-made solutions that are perfectly tailored to your individual requirements. In doing so, we rely on the latest technologies and the high level of expertise of our employees in order to offer you the best possible quality and efficiency. We see ourselves as your reliable partner and do everything we can to exceed your expectations. Our close cooperation and transparent communication guarantee a smooth execution of your projects. In doing so, we always remain flexible and adapt to your needs. Let yourself be convinced of our performance and commitment. We look forward to meeting you and working with you to successfully implement your projects. Contact us today!

Founded

2019

Employees

10 - 20

Certifications

Paderborn

Germany - 33106

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

The Feinblechtechnik is our profession For over 40 years we have successfully represented our services on the market. As a traditional company, we offer services in the field of sheet metal processing, laser cutting, punching and nipple technology as well as various bonding techniques. With us you get individual products just as complete assemblies. We manufacture according to customer sketches, drawings or samples. Starting from raw material through to visual design (surface) They get us a finished product, from single pieces to series. The data necessary for the production tooling and fixtures created in-house mold manufacturing, modern machinery is available. Our world-class services you are absolutely convincing.

Founded

1965

Employees

5 - 10

Certifications

München

Germany - 81829

We are a powerful and flexible medium-sized partner in all aspects of sheet metal work and mechanical galvanizing coating. Since 1888, we have steadily expanded our production depth and can now run with about 80 employees, both single and serial orders flexibly, quickly and with high quality. Short-term appointments are familiar terrain. Competent partners support us in many areas, such as electroplating and powder coating, with the same flexibility and quality. In sheet metal processing, we can look back on decades of experience and have a powerful, modern machinery. We handle small, medium and large sizes (1500x3000 mm), folding is up to 4000 mm possible. Sheet metal parts are manufactured in every imaginable shape and of course with the highest precision. Laser cutting, edging, stamping, welding, and many other procedure we maintain. Metal spinning is another of our method.Even for simple work such as beading, beads and rounds we have the appropriate equipment. Applied welding processes are electrodes, MIG / MAG and TIG. The materials of black metal, structural steel, stainless steel (V2A, V4A) and aluminum are processed. The production of sample parts and support to the production stage are also among our specialties. We offer reliability and quality of smooth sheet metal to finished coated and if necessary up to the mounted component at a high level. Of course, we are certified to ISO 9001:2000. Our quality management for all processes is continually evolving. Our services in the field of corrosion protection are hot-dip galvanizing, Kleinteilverzinken and mechanical coating (Mechanical Plating, also known as a mechanical galvanizing). Our galvanizing plant is well equipped for galvanizing of large and small series as well as individual parts and small parts. The High-temperature has been proven for many types of small parts (stamping parts and threaded parts).The high durability of the products goes hand in hand with the excellent corrosion protection provided by hot dip galvanizing. Our success is based on the reliability and durability of our products, which are processed by the hot-dip galvanizing and mechanical coating. Mechanical coating is particularly interesting for small parts made of high-strength steels. We also offer the Almac coating. For further information and offers we like are available.

Founded

1888

Employees

50 - 100

Certifications

Weilheim/Teck

Germany - 73235

Dr. Franke GmbH & Co. KG are nationally and internationally as recognized partner in the field of stamping and forming. The field-proven know-how is based on a many years of experience from the beginnings of plate lock- technology to modern technology in sheet metal forming. Here you have a dedicated development and Staff team is available that with sound knowledge a wide range of manufacturing dominated alternatives. ° STAMPING ° DEEPDRAWING ° FINEBLANKING ° WELDING ° MOUNT ° COATING ° CONSTRUCTION ° TOOL ° PROTOTYPE With individual, custom manufacturing for large- and small series presents Dr. Franke GmbH & Co. KG is the constantly changing product and logistics requirements of the international industrial Only by Dr. Franke documented real customer focus.

Founded

1865

Employees

50 - 100

Certifications

Solingen

Germany - 42657

We are a small family run company in Turkey. After 33 years of experience in Germany, we decided, to set up the production facility in Turkey. The better wage structures and our second half culture has helped us in our decision. After 33 years didactic stay in Germany, we know your values and feelings very well appreciated. They comprise, first and foremost the quality of the service and of course the price ... Also find a small step to us ... you will see how you can achieve great strides ...

Founded

2003

Employees

10 - 20

Certifications

Konya

Turkey - 42050

Diming manufactures standard serial sheets and roofing accessories as well as various sheets and semi-finished products to order. We also offer punching, cutting and bending of sheet metal of various lengths and thicknesses. We provide welding and assembly services for various components.

Founded

Employees

20 - 50

Certifications

Ljubljana-Dobrunje

Slovenia - 1261

Homers Production is a young Slovakian company founded to produce modular houses from self-made sandwich panels. In the meantime, our company is fully ready for production; however, it is underutilized due to a lack of product approvals. We are therefore looking for contract work in the area of punching and bending for our sheet metal processing - gladly in conjunction with the powder coating from our local partner.

Founded

Employees

10 - 20

Certifications

Košice

Slovakia - 04001

Founded

2005

Employees

100 - 200

Certifications

Velbert

Germany - 42551

Hirtenberger precision engineering for decades the specialists for chipless metal processing. A company of long-established group of companies Hirtenberger AG. Our staff in the design and tool to solve even the most difficult customer. These are our most advanced technologies available. Their products are manufactured on the most modern eccentric presses or punching and bending machines (Bihler). With these technologies, we can offer you the most economically and technically best solution tool. The specialists for chipless Metalworking Stampings large and small series Complicated stamped and bent parts Moulded stampings Assemblies

Founded

1993

Employees

50 - 100

Certifications

Hirtenberg

Austria - 2552

Manufacture of stamping, drawing, deep drawing and stamping bending parts, assemblies, welded assemblies, plastic covered parts, stampings and plastic tools, special machine

Founded

1995

Employees

200 - 500

Certifications

Scheibenberg

Germany - 09481

VARIALUX GmbH

In addition to turning and milling, VARIALUX offers the metal forming of metal spinning, which is only rarely offered. This is done both conventionally and CNC-controlled. Other processes: deep drawing, stamping and edging. Welding and soldering are just as much part of the scope of production as painting and powder coating after prior surface treatment. Special processes for processing lead parts have been developed for production in medical technology. B. include lead welding and lead gluing.

Founded

1990

Employees

20 - 50

Certifications

Arnsdorf

Germany - 01477

Your partner in mechanical subcontracting We offer a subcontracting service for mechanical components and assembled machines, in which, starting from the customer's project, we study its industrialization, we identify the most suitable production process, we rely on the most suitable suppliers for each individual production phase.

Founded

Employees

5 - 10

Certifications

Parma

Italy - 43123

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

VRP Group is an engineering company founded in Bursa in 2024 with 25 years of industry experience and supporting various sectors. We add value to our customers in a wide range, under one roof, with our 5 different brands, in line with the needs and expectations of our customers in every process from design to manufacturing in the fields of Sheet Metal Mold, Thermoforming, Aluminum and automotive accessories. VRP Engineering is the brand establishment of VRP company, which was established in 2024 with 25 years of experience in the sector. We are an engineering company specializing in the production of sheet metal molds and parts, as well as customized products designed to meet the specific requirements of our customers. Our main field of activity is the sheet metal mold industry and we can provide services with our partner companies in the fields of automotive, white goods aviation and defense industries.

Founded

2024

Employees

20 - 50

Certifications

BURSA

Turkey - 16220

Founded

2019

Employees

10 - 20

Certifications

Gaziantep

Turkey - 60709

Based in Normandy, we are experts in stainless steel manufacturing, from cutlery to deep-drawn components featuring invisible laser welding. Our production capabilities include an in-house continuous vacuum annealing furnace, along with high-capacity, fully automated lines for deep drawing, welding, and polishing.

Founded

Employees

200 - 500

Certifications

Vire

France - 14500

"Kupro Email" LTD is a traditional and long-standing manufacturer of enameled household dishes and construction brackets. In addition to those, the company also produces fireplaces for heating on solid fuel and the necessary accessories for their operation - enameled pipes for stoves, heat exchangers (pounds), underlays for fireplaces.

Founded

Employees

20 - 50

Certifications

Shumen

Bulgaria - 9700

Since 1971, convince the achievements of our house in a highly competitive market of the tooling and prototype construction. Uncompromising quality, the profound Knowledge and commitment of our staff, and the latest production technology shape our corporate philosophy. To design innovative and professional product solutions and produce, is our daily challenge that we perceive competently and with great joy.

Founded

1971

Employees

50 - 100

Certifications

Gütersloh

Germany - 33334

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

Deep drawing

Deep-drawing is a part of Sheet metal processing and the most important forming method for the production of sheet metal parts. According to the definition of DIN 8584, it is tensile compressive forming and the processing is carried out by simultaneous tensile and compressive stress in different operating directions. The drawing method most commonly used is deep-drawing with rigid tools from tool making. The tools consist of a punch, a die and a sheet holder. The sheet metal blank is fixed by the sheet holder and during immersion the stamp spans the sheet in the board across the die radius, pressing it into the die (also called drawing ring). In doing so, the required punch force constantly increases until the dead-centre position is reached. The edges of the punch and the die are rounded, otherwise the sheet might tear. If the roundings are too large, the sheet at the end of the draw can no longer be fixed by the downholder, which may lead to wrinkling. If the draw depth is not reached in a single step, the draw is executed in several steps, especially in case of thick sheet metals.