Deep hole drilling for any material

Find specialized suppliers for deep hole drilling on Techpilot. Our platform offers access to suppliers who use advanced drilling technologies to create deep and precise holes in materials. Benefit from comprehensive market transparency and optimize your supplier selection.

2540 suppliers for Deep hole drilling

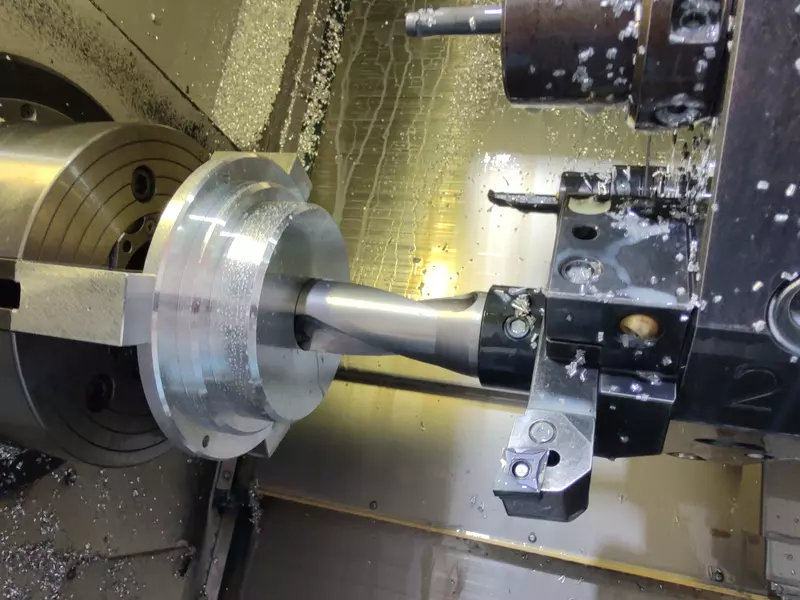

Welcome to the Nachbur AG, your specialist for turned parts, precision turned parts, turned parts and assembly The Nachbur AG is a specialist for components and turned parts. So we manufacture precision turned parts, turned parts and turned parts. In addition, the assembly is part of our field of activity. We will work for you as a contract manufacturer. Whether CNC turning, production of precision parts or assembly - we put the customer at the center. 1947, our company was founded for turning parts and assemblies. Since then we have gained extensive know-how for the production of precision turned parts, turned parts and lathe parts. A strength of our company is the high quality of the turned parts and assemblies. All production processes of Decolletage and assembly are strictly monitored. Our quality management system for the rotating parts is also certified. Also an environmentally conscious production of precision turned parts, turned parts and lathe parts sets us apart.For the environmentally friendly production of Decolletage our professionals develop special programs. For example, we pay attention during the shooting as well as the assembly always on the conservation of resources. Our environmental management system for the rotating parts is also certified. In our Dreherei the latest machines for turning are available. For the rotational work naturally includes sanding and cleaning the long turning parts, turned parts, and precision turned parts. Thanks to a strong partner to deliver the CNC takes place - Turned parts worldwide. The Nachbur AG offers customers in the filming of various solutions. We manufacture pattern of precision turned parts, turned parts and lathe parts. Do the rotating parts to the customer, we ask this in produce small to large series. Our precision parts and Turned Parts are used in various industries. How to find long turning parts, precision turned parts and turned parts used in medicine, hydraulics and electronics industry.

Founded

1947

Employees

50 - 100

Certifications

Holderbank

Switzerland - 4718

Founded

1995

Employees

20 - 50

Certifications

Brvnište

Slovakia - 018 12

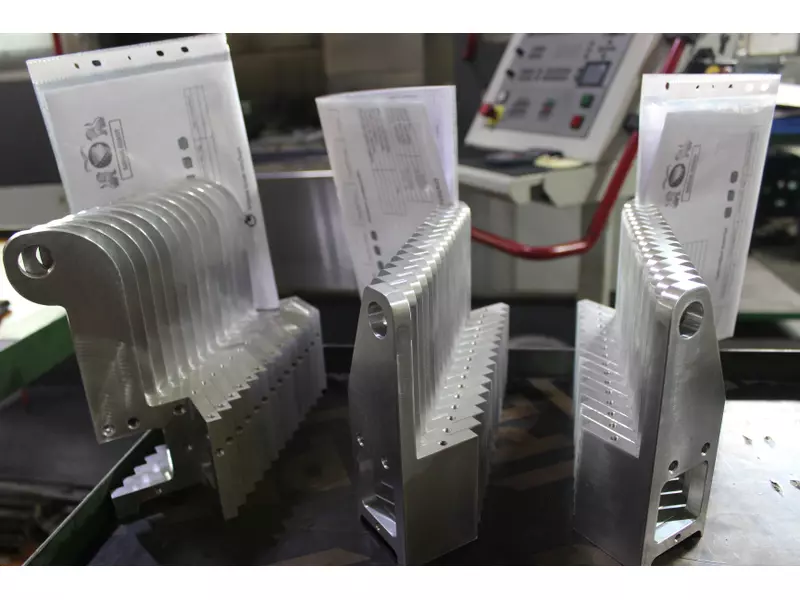

We manufacture prototypes and series of precision mechanical parts in aluminum alloys, steel, stainless steel, plastic, Teflon and titanium, for an exclusive clientele in the automotive and motorcycle racing sectors, aeronautical and aerospace vehicles, automatic machines for industry and packaging and dental implantology. We create the finished part starting from the customer's drawing or 3D model, with control and validation of the production process and product traceability: - design with Cad / Cam software, Virtual Machining and control plans with Solid Inspection - import from any standard CAD format - manufacturing of parts from solid with continuous milling on 3-4-5 axis machining centers on palletized machines, turning, EDM, drilling, lapping and finishing - special processes (heat and surface treatments) carried out in collaboration with the best partners on the market - tests in the metrology room at controlled temperature and humidity set up with 3D measuring machines, control certificate with penetrating liquids performed by qualified 2nd level personnel - industrialization processes validated with FAI and configuration management - product traceability guaranteed with test reports and issue of the certificate of conformity - quality management system certified according to the aeronautical standard UNI EN 9100 and according to UNI EN ISO 9001 For over 40 years we have been at the forefront of technology to offer the customer the highest quality available on the market for complete, customized solutions, guaranteed in quality, delivery times and after-sales assistance.

Founded

1982

Employees

10 - 20

Certifications

Nonantola (Mo) Italy

Italy - 41015

The company's beginnings go back to 1945, when the Nafta Lendava company started its operations. Within the sole proprietorship Nafta Lendava, the activities are organized in the areas of mechanical engineering and maintenance. Nafta strojna has been an independent company since 2002, based in the far north-east of Slovenia on the border between Hungary and Croatia. The geographical location of Lendava is the cause of the ethnically mixed population and at the same time represents the hub of important transit routes in Europe. The company specializes in the manufacture and maintenance of devices for the storage and handling of liquid energy sources as well as the manufacture and installation of steel structures. The company's core activity is the manufacture, installation and maintenance of investment equipment for the needs of the process industry. Our most important customers and business partners are companies in the field of mineral oil and chemical activities.

Founded

1945

Employees

100 - 200

Certifications

Lendava

Slovenia - 9220

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are committed to a continuous search for excellence in precision machining. Today we produce special components to customer specification 24 hours a day, 7 days a week.

Founded

1980

Employees

20 - 50

Certifications

Santa Maria di Zevio - Zevio - Verona

Italy - 37059

Ribermold, High Precision Molds is a Portuguese mold maker, located in Marinha Grande, District of Leiria, Portugal. Dedicated to the manufacture of high precision molds for several industries, such as automotive, aeronautics, electrics and electronics, Ribermold keeps up with the edge technologies and bets on innovation. The combination of the cutting edge technology and a motivated and rigorous team with more than three decades of experience in the design and manufacture of molds defines the way how Ribermold faces its business.

Founded

1987

Employees

50 - 100

Certifications

Marinha Grande

Portugal - 2430-904

NURSAL Makina is a manufacturer & exporter company. We are specialized in sheet metal fabrication. Our core business is welding Our capabilities: - Laser cutting & bending - Press forming - MIG/MAG, TIG - Pipe, profile bending & cutting - Powder coating - Wet painting - Chrome plating, electro galvanizing, hot dip galvanizing - Machining & grinding We have a wide range of products including tanks, barriers, platforms, guards, conveyors, stairs, cabinets, frames, machinings etc. Our target sectors: Construction, Automotive, Hydraulics, Textile, Agriculture, Marine, Offshore For more information about our company you may take a look at our website www.nursalmakina.com/en/.

Founded

2014

Employees

10 - 20

Certifications

IZMIR

Turkey - 35475

We are a family company established in 1993. We manufacture the following: machinery and equipment, molds, zigs, metal construction, CAD-CAM, moulds for injection molding, investment casting, 5- axis milling (aluminium and steel) and welding (steel constructions and stainless steel) Since 2003, we are also engaged in manufacturing sports gear especially for the Ski-industry . Today our company has over 27 specialized, highly experienced technicians.

Founded

1993

Employees

20 - 50

Certifications

Lesce

Slovenia - 4248

Since our founding, we have worked with many clients in the area. The great service starts and ends with experienced and friendly professionals, so we were very careful to select only the best ones for our team. We complete projects efficiently and on time, and our goal is to build lasting relationships with our clients.

Founded

2020

Employees

< 5

Certifications

Bábolna

Hungary - 2943

Forstek is a tool shop established in 1993 formed from former mould workshop of Glass Factory Steklarna Hrastnik. We are equiped with modern CAD/CAM systems like Siemens NX and Mastercam, modern CNC machines including 5-axis milling machines, 3D CMM and portable measuring hand. We design and produce moulds for glass industry (IS, press and press-blow moulds) and blister tools for blister packaging lines. Apart from this we offer machining of various mechanical parts for variety of industries. We have ISO 9001:2015 cerificate.

Founded

Employees

50 - 100

Certifications

Dol pri Hrastniku

Slovenia - 1431

KEMTHAR specializes in producing high-quality components and accessories for commercial vehicles. Equipped with state-of-the-art machinery, we ensure precision and efficiency in every product. Additionally, we offer expert machining services on a subcontracting basis, tailored to meet your specific needs.

Founded

Employees

10 - 20

Certifications

Mira de Aire

Portugal - 2485

BOSNIA GRAFIT d.o.o. is a family company that was founded and started operating in 2014 based in Klokotnica in the industrial area of the Municipality of Doboj Istok in northern Bosnia and Herzegovina. It mainly deals with the production of mechanical components for various sectors between here: - mechanical / textile sector - land drilling sector - thread sewing sector (book production) - food industry - general mechanical sector In the 300 m² commercial space, the company has machines for milling, turning and grinding metals and non-metals (aluminum, brass, steel, stainless steel, plastic, graphite ...) All mechanical components and manufactured assemblies are subject to control during the production process and at its completion. You can request a quote without obligation at any time. To do this, just send an email to the address ----->dino.cajic@bosniagrafit.ba Italian - Bosnian and written English are the languages of correspondence.

Founded

2014

Employees

5 - 10

Certifications

Doboj Istok

Bosnia & Herzegovina - 74207

Welcome to the company Helmut Nauber eK Feinmechanik & Maschinenbau, Your partner from Hamburg for turning and milling work as well as mechanical component manufacturing Only the fairest and most productive companies are able to work in partnership with their customers and the highest To meet demands. With this in mind, we have been serving medium-sized companies and large corporations in the market segment of industry and shipping for many years. We manufacture individual pieces and series productions in standard or special production / special machine construction. uncomplicated flexible competently reliable See for yourself. Our services include: Component manufacturing custom made Manufacturing of individual parts Production of small, medium and large series Repair and repair work Hard turning, drilling and pushing Sandblasting of parts / components Mechanical production on conventional / CNC turning and milling machines Fixture construction

Founded

1953

Employees

5 - 10

Certifications

Hamburg

Germany - 22175

ZERN Mechatronik Gmbh is a family-run business and is divided into 9 different divisions, which are dedicated to the following activities. Production of: Large-format metal 3D laser printer; Retail products; CNC contract manufacturing; Operating a private industrial park; Steel construction; Product development for third; Rapid prototyping; Department of Commerce; Defense Technology. The operating area comprises 12000m².

Founded

2000

Employees

5 - 10

Certifications

Bischofshofen

Austria - 5500

Founded

1989

Employees

50 - 100

Certifications

Eching

Germany - 85386

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Family business 5 axis milling machines 4 pieces 1 turning / milling machine 3 conventional lathe 2 CNC lathes Processing

Founded

2018

Employees

5 - 10

Certifications

Augustdorf

Germany - 32832

Yildiz-CNC Zerspanungstechnik is a medium-sized family company based in Hüttenberg (Hesse). Since 1996, high-precision industrial components have been manufactured on modern CNC-controlled turning and milling machines. On an area of over 1,000 square meters, we produce for our customers from the fields of mechanical engineering, medical technology, the optics industry, the food and automotive industries. We manufacture prototypes, single and sample parts, small series and series in the medium quantity range. As a technology partner, we advise our customers on all manufacturing issues, from the development of a component to series production. We look forward to getting to know you as a customer and partner.

Founded

1996

Employees

5 - 10

Certifications

Hüttenberg

Germany - 35625

We are a young, modern company in the CNC contract manufacturing sector. Our quality standards as well as our adherence to deadlines are the top priority of our company. This is the only way we can identify with every product and every service. That is why we have set up this homepage for you so that we can inform you even better about our services. The service-oriented customer care is an essential cornerstone of our successful corporate strategy. Fulfilling your wishes is our focus. Qualified employees provide friendly and expert advice. Our extensive range of services leaves nothing to be desired. Convince yourself of our range of services and our diverse range of services in the field of CNC contract manufacturing. Our products are characterized by the highest quality and the most modern manufacturing technology. Of course we offer you all this at a fair price. Every employee has special knowledge and many years of professional experience in the field of CNC contract manufacturing. These are reflected in our products. You as a customer benefit from this, now and in the future!

Founded

2012

Employees

5 - 10

Certifications

Rosenheim

Germany - 83026

The machines and drives Maschinenbau GmbH & Co. KG from Güstrow manufactures complete customer order, or edited after drawing Kundenbeistellungen. We are contract manufacturer in the areas of turning, milling, gear cutting, grinding and broaching. Our machinery is to small - designed and medium batch production. We can offer our customers the assembly of components including coloring. We are certified according to DIN EN ISO 9001:2000 and DIN EN ISO 14001:2004 Information about the structure of our company, see http://www.maguestrow.de

Founded

1992

Employees

100 - 200

Certifications

Güstrow

Germany - 18273 Güstrow

Rudi Göbel GmbH & Co. KG, based in Helmbrechts, is managed by owner & managing director Frank Pichler. The company was founded in 1957 and, with its three locations and 500 employees, specializes in the production and sale of plastic, metal and silicone solutions. The extensive product range, as well as our own tool shop with over 100 specialists, includes precision components, weight-reduced high-performance components and system solutions for displays and controls. The offer is aimed primarily at power electronics, the automotive sector and industrial technology. The high-quality and innovative products from Rudi Göbel GmbH & Co. KG impress customers from all over the world. In addition, the company offers a comprehensive range of services that combines all development, toolmaking, manufacturing, finishing and assembly work. You can find out more about the services offered by Rudi Göbel GmbH & Co. KG on the company's website.

Founded

1957

Employees

200 - 500

Certifications

Helmbrechts

Germany - 95233

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge