Composite tools: realize better purchase prices

Discover specialized suppliers for follow-on composite tools on Techpilot. Our platform connects buyers with suppliers who manufacture high-quality tools for various applications. Use the e-sourcing process to find the best suppliers.

302 suppliers for Follow on composite tools

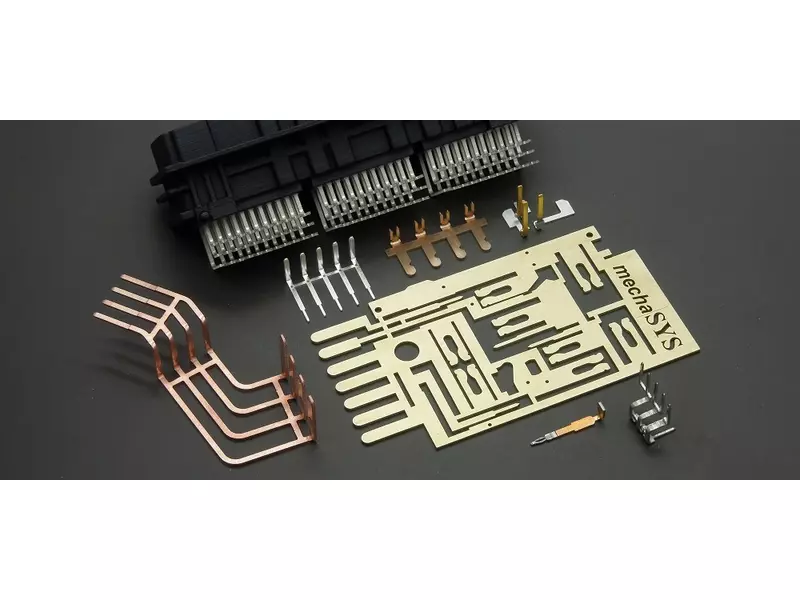

* laser cutting, mirco-laser cutting * mirco-waterbeam cutting * stamping of functional areas or driven by quantity * coining and bending (most without any tool-costs by our tool-box and self-developed bending-technology) * plating ONE SINGLE-CONTACT from 3D-data to final parts - www.mechaSYS.de

Founded

2011

Employees

10 - 20

Certifications

Pforzheim

Germany - 75177

Our advantage Stay more agile faster and more productive Modularity to the power of three is the catchy short formula for a new idea: the modular design concept of SBT production machines for metal parts production − for more options, more speed and more output. SBT production machines were originally designed as a link between classic automatic punching machines and automatic punching machines. They combine the advantages of both systems — the flexibility of the punching machine and the short set-up times or long tool life of the automatic punching machine.

Founded

1980

Employees

20 - 50

Certifications

Wöllersdorf

Austria - 2752

We are an owner-managed, medium-sized company in the tool and mold making sector. The family business has been based in the Höxter district in East Westphalia since 1961 - in the three-country corner: North Rhine-Westphalia, Hesse and Lower Saxony. Our many years of experience in the field of tool design and production make us - a team of young and dynamic employees - a competent partner for our customers. Cooperation and Innovation: The employees are the most important element in our endeavors to look after customers at a high level, to develop and implement solutions. Personal interaction and cooperation are characterized by appreciation, recognition, team spirit and mutual respect. Communication is open and constructive. Every employee feels responsible for the entire company and is called upon to make innovative suggestions for improvement to ensure that the existing procedures and processes are optimal. So everyone contributes to the overall success of the company.

Founded

1987

Employees

10 - 20

Certifications

Borgentreich

Germany - 34434

From design to stamping tooling to the finished stamping. techno plus tooling specializes in the design and manufacture of sophisticated punching, bending and forming tools. The following tool types are built by us: thermoforming mold, progressive die, transfer tool hand insertion tool and notching. We extend our experience constantly, because even the series production of the stamped parts and maintenance of the tools in our Punching tool carried out by our staff. Technical know-how is combined with practical experience in our production. This produces robust tools that can be serviced easily and produce inexpensive items. In our tool, the items for the punching tools are made. Our machinery ranging from CNC milling on CNC turning and CNC grinding up to the wire cutting and bead blasting. With the help of our 3D measuring machine, each part is tested and ensured the required quality

Founded

1978

Employees

20 - 50

Certifications

Hard

Austria - 6971

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Welcome to Just in Time precision parts Our company is working for many companies from different industries. With over 10 years experience and modern machines, we are your partner with expertise and high quality standards. With our extensive range of machinery and skilled professionals we produce individual parts, prototypes and small series of one piece to thousands of pieces. Together with our external partners, we provide you with a delivery from raw through to hardened or surface-coated part from one source. Just in Time For precision parts customer service means to offer as a production and service company in every respect what we expect from our suppliers. The only way to build a foundation for a trusting relationship. Our services are: Short reaction times Meaningful Offers Reasonable price / performance ratio Advice to our clients in the design of Products in terms of economic production. Consistent high level of quality Exact deadlines Our production processes are very flexible. When necessary, our staff is ready to use on weekends. This puts us in a position to ensure a timely output with almost zero error tolerance. Just come to us - we stand by our word!

Founded

2002

Employees

< 5

Certifications

Göppingen-Ursenwang

Germany - 73037

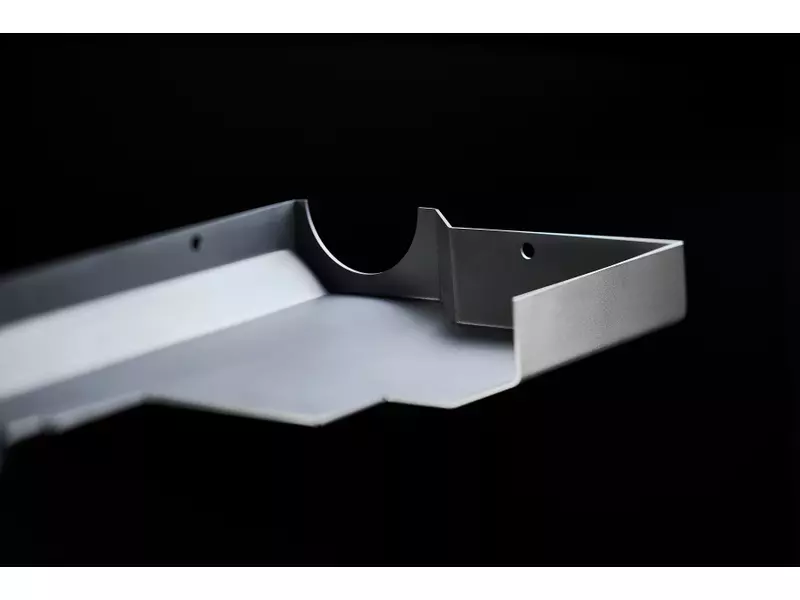

When it comes to sheet metal processing, you have come to the right place at WSM Schäfer. Our wide range of services ranges from the manufacture of laser, stamped, formed and deep-drawn parts to the development and manufacture of punching tools and the assembly of complete assemblies. Decades of know-how, experience and passion flow into each of our customers' orders.

Founded

1983

Employees

20 - 50

Certifications

Wehingen

Germany - 78564

We are a small innovative company with 8 employees Saarland in contract manufacturing. We produce 2D and 3D milling parts in the field of small mechanics (max.800x600x550) from different materials for the tool, fixture, shapes - and mechanical engineering to milled parts in 5-axis range. * Knife * flange steels * contour stones * Welding Supplies * stamp * dies * flashings * We manufacture as desired including material and required heat and surface treatments. We have a variety of standard - and system-related data exchange - the interfaces as a seamless data transfer with CAD - is given systems and different formats. We work with Cimatron (CAD / CAM) Tools, fixtures, fittings, welded parts, Medizientechnik, scrapers, punches, 3D, 2D, 5Axis, Intake Manifold, fork bridge, mounting device, fixture

Founded

2000

Employees

20 - 50

Certifications

Marpingen

Germany - 66646

Metal Technology Annaberg GmbH is a manufacturer of stamping and bending parts of non-ferrous metals and steel strips. The focus is on clamping and contact parts and fasteners for panel builders and equipment construction of low-and high-voltage technology in the electrical industry. The company and its employees share a centuries-old tradition of metalworking in this region with the expertise, technology and automation of a future-oriented supplier in a unique way. Our metal production produced on an area of 2,500 square meters, the company's own tool made to an area of 400 sqm. Metal Technology Annaberg specializes in terminal and connection technology for connecting electrical cables: Contact bars of copper for Busbar adapter - Made to Bihler machines and thread bridges for fuse base in embossed design as well as springs made of V2A steel, printing and retaining springs to secure the necessary electrical connections made on progressive dies and Bihler machines. More products are products for power transmission by contact and rail technology as well as finished assemblies and jump derailleurs. (Contact and connection parts for fuse holders and distribution systems, box terminals - fasteners for a variety of situations in the terminal equipment technology, made on Bihler machines and completes on special machines, conductor terminals for busbar technology) In addition to all common tooling procedure of the toolmaking modern erosion and numerically controlled milling and grinding technology are the production-technical base for the production of Bihler and follow-on composite tools. Highly qualified and experienced staff ensure high standards and are available for a maximum of customer orientation. Tags for Google: metal forming, metal technology, Annaberg, Saxony, Erzgebirge, metal forming, punching and bending, Bihler, grids, EBU, eccentric presses, forming machines, assemblies, assembly, welding, Königswalde, Witron, material flow, lean production, lean manufacturing, steel strip, pressed copper, brass, bronze, steel, stainless steel, clinching, joining,

Founded

1998

Employees

50 - 100

Certifications

Königswalde

Germany - 09471

Lohmann Werkzeugbau GmbH & Co. KG is a future-oriented, medium-sized company and was founded in 1991. With over 20 years of experience, we have extensive know-how in the technology of tool and mold making. Our focus is on plastic injection molding, hydroforming, cutting, and prototype construction. Our extensive and state-of-the-art technology and machine park enables our team of over 20 employees to solve tasks quickly and in the best quality. We have been known for this since the company was founded. Our customers are located in the automotive, food, packaging and general consumer goods industries, among others

Founded

1991

Employees

10 - 20

Certifications

Balve

Germany - 58802

![MOLLIS ANTONIO srl [SCAMM Group] Logo](https://prod-app-techpilot.s3.eu-central-1.amazonaws.com/public/125211/logo/47e44520-0cb2-4dae-ba87-d1fcc0a6b45c/220x220/logo%20mollis%202021%20rgb%20300dpi.webp)

SCAMM Srl and MOLLIS srl supply service and equipment for metal sheet deformation and assembling. MOLLIS produce parts and assembled component made in metal sheet. SCAMM supply dies, hydraulic press and complete process line for metal sheet deformation

Founded

1946

Employees

50 - 100

Certifications

Treviolo

Italy - 24048

Founded

1924

Employees

200 - 500

Certifications

Endingen

Germany - D-79346

Founded

2016

Employees

10 - 20

Certifications

Erschwil

Switzerland - 4228

On 14,500 m², over 245 employees are ready for any challenge at state-of-the-art facilities. Krieg plans, designs, punches, lasers, welds, edges, finishes and assembles your metal components, metal housings and cabinets. A perfectly coordinated workflow, our powerful machinery, together with our professional teams, make it possible to meet deadlines and always produce the best quality at the best prices. Krieg works for the following industries, among others: mechanical engineering, plant engineering, measurement and control technology, food industry, renewable energy, shop construction, medical devices, general electrical appliances, automotive industry, transportation engineering. Challenge us - we'll do it!

Founded

1975

Employees

200 - 500

Certifications

Heinsberg

Germany - 52525

The powerful, modern machinery, which was founded in 1958 M. Cap GmbH includes automatic punching machine, eccentric and hydraulic presses and a 2D laser cutting system. The development and construction of tools and tube bending belong to the range. From prototype to mass production you receive everything from one source. Punching, pressing, drawing: With a press force of up to 400 tons. be processed up to 6.0 mm strap width up to 630 mm and strip thicknesses. Steel bar can be stamped up to 200 mm x 20 mm and bent be. Toolmaking: Together with you we develop the economic and technical sinvollste solution for your applications. In our tool, we design and produce for you advanced composite tools with CAD, CAM, CIM, CNC-based manufacturing. 2 D laser cutting: The process completes our manufacturing program. On our 5 kW laser system, we can process the following material thicknesses: - Up to 25 mm mild steel - Up to 20 mm in stainless steel - Up to 12 mm of aluminum Tube bending: On CNC controlled rotary rollers and mandrel bending machines we process pipe sizes from 4 mm to 50 mm diameter.Steel pipes, copper pipes, brass pipes, stainless steel pipes. Welding: We manufacture complete assemblies including MAG, MIG, TIG and projection welding process. In the case of large numbers and the highest quality standards effective Robot installations. Further processing: Cut to Mehrspindelbohrwerken and we form thread to M20. The surface of our products can be improved by trovalizing if necessary. Galvanic processing procedures as well as paint and powder coatings gehöhren with the delivery. Quality Management: Our company is certified according to ISO 9001:2000. With modern 3D measuring machines and Prüfleheren we constantly monitor the quality of our products.

Founded

1958

Employees

20 - 50

Certifications

Medebach

Germany - 59964

Manufacturer of connectors and contacts with our own production and our own tool shop

Founded

1942

Employees

> 1000

Certifications

Mühldorf

Germany - 84453

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

More than 50 years of experience in tool production. Specialized in plastic injection and sheet metal forming tools 55 employees 80% automotive industry 50 new tools a year Manufacturing of hard steels in the range of 1500x700x600 Maximum tool weight 5 tons

Founded

Employees

50 - 100

Certifications

Szekesfehervar

Hungary - 8000

The company has been dedicated for more than 30 years of development and production of complex tools for stamping and forming. From the initial idea, through development and construction, the prototype to series production, you can have things under one roof. As a contract manufacturer we are happy to produce for you from small series to mass production - exactly the number of pieces that you need. We manufacture tools for stamping and metal forming. With precision - in perfection! From a simple hole tool, to complex progressive dies, be carried out at the various feeding stations cut hole and bending operations. Tools with 3-D machined flexures and actuated valve cross-inclined punch are part of our range of services, such as drawing tools for the production of sheet metal parts, which can accommodate precision ball bearings. In addition, we produce tools for smooth cutting and trimming products, final ridge and straightening tools for casting and die casting industry.EDM and CNC milling operations are carried out as contract manufacturing. PROTOTYPES AND ZERO SERIES: CREATING KNOWLEDGE IMPRESSION. We focus on holistic development of forming tools. To make your ideas "grasp", we use the method of rapid prototyping. Through rapid prototyping, we are able to quickly show our clients a prototype of its desired stamped and / or formed part. Once the tool to enable us to run a first pilot series in our home. The knowledge gained in Sheet Metal Forming the first edition then - if necessary - used to optimize the tool for serial production. For the production of the prototype, we use a different method. Production tests can be performed with a A geo-test press with 125 tons of pressure and production presses with a pressing force of up to 400 tons. Can be used for composite tools with a total length of up to 2500 mm. Complex shapes, intricate geometries or simple tool requirements - precision is required for each tool. The combination of many years of know how with the necessary care can arise daily quality products in our home. Modern technology is a critical performance factor in the construction of tools. Customers can therefore be confident that their tool is manufactured to ultra-modern machines. For multi-axis machining centers with automatic tool changers provide for economic production. For the testing of tools including a Ageo-test press with 125 tons of pressure and production presses up to 400 tons of pressure available to us. Homepage: www.volkergehlen.de Homepage: www.schulte-press.de

Founded

1981

Employees

10 - 20

Certifications

Velbert

Germany - 42553

Founded

1973

Employees

100 - 200

Certifications

Runding

Germany - 93486

For over 17 years the company GMTI, Golz Mould & Tools International UG, reliable producer of high-quality molds and dies for metal, plastic and rubber products for the Automotive industry and vehicle - Aluminum and zinc die cast parts such as axles, housing - Plastic parts such as bumpers, valves, headlight covers, manifolds, 2-component parts, etc. Lighting industry and electrical industry - Plastic parts such as sockets, switches and other lighting equipment Air and space industry and military technology - Aluminum, zinc die casting and plastic parts for high-precision requirements Medical - Custom-made of aluminum, zinc die casting and plastic for high-precision Requirements Furniture industry - Aluminum, zinc die casting and plastic parts such as handles, hinges, rollers, buttons, etc. Air + cooling technology - Rubber and silicone parts, seals etc. Machine Tools - Tools according to drawing We manufacture molds and tools for small - and large-scale production, as well as Prototypes The dimensions of the parts amount to 1 mm - 3,000 mm It can be processed part weights up to 20 kg. GMTI is an international company with manufacturing facilities in Eastern Europe (especially Poland) and Asia. Together with our cooperation company, we have a large number of experienced staff, from the designer to the machine operator. Through expert advice, a quality range of precision tools and on-time delivery, fr significant advantages to our customers.

Founded

1997

Employees

< 5

Certifications

Arnbruck

Germany - 93471

Consulting, development and production of means of production, machines and components from engineering to manufacturing detail to the complete system, we assume responsibility for the project. Sheet metal working: Your manufacturer of precision parts, assemblies, and partner for complex manufacturing solutions in sheet metal processing. The flexibility of the plants, together with the creativity of professionals enables new solutions. Manufacturing noble parts: Design and fabrication of components, series and pre-finished assemblies including post-treatment, logistics and functional test. Sharpening and Rental Service: The sharpening of ABB is your guarantee for cutting tools of the highest quality. Both the sharpening of standard and special tools, as well as in the procurement of new tools you need to make any compromises. Our rental services for measuring instruments, standard and special tools offers a wide selection at very attractive terms.It is much more economical for you to rent from us than to buy rare and short-run and manage resources. These include in particular oversized tools and measuring equipment that you can find and hire. Heat treatment: The services offered by the heat treatment comprises the traditional methods such as annealing, hardening, tempering in an open atmosphere, an inert gas or vacuum. In addition, we offer special techniques such as nitrocarburization, an environmentally friendly surface hardening process, with impressive characteristics, as well as the necessary pre-and post-treatments. A unique service we offer regarding expertise and infrastructure in the tempering of aluminum alloys. Translation by Google Translate

Founded

2015

Employees

100 - 200

Certifications

Kleindöttingen

Switzerland - 5314

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge