Laser engraving: realize better purchase prices

Discover specialized suppliers for laser engraving on Techpilot. Our platform connects buyers with suppliers who use advanced laser technologies to create precise and high-quality engravings. Use the e-sourcing process to find the best suppliers.

187 suppliers for Laser engraving

The owner-managed company Aloys Kleier is a service company in the field of small-scale component manufacturing, hardware and electrical installation. As a cooperation partner of the industry, we bring by screws, rivets, welding and gluing together on 4000 m² of production space, what belongs together. In addition, our staff have many years of experience in the fabrication and installation of staircases, ramps and railings, pipelines, metal and welded constructions of all kinds Our range of services is complemented take over all activities of a classic Metallic, ie including sheet metal and metal processing including welding, Kant, drilling and sawing and we done quickly and efficiently. The customer gets to us all from one source. We service the products from purchasing to warehousing, manufacturing, assembly, logistics and all emerging problems. Flat hierarchies fast communication and flexible production methods are guaranteed. All orders we carry uncompromising from the complete satisfaction of the client. Partnership based on trust and maximum quality form the common success for both sides and are the basis for a long-term cooperation.

Founded

1982

Employees

50 - 100

Certifications

Vechta-Calveslage

Germany - 49377

For more than 60 years H.P. Kaysser GmbH + Co. KG has been belonging to the internationally accepted best sheet metal processors on the market. As a customer-oriented, family run medium-sized enterprise we produce with more than 300 dedicated employees at our locations in Nellmersbach (near Stuttgart, Germany) and Bistrita, Romania. Our strengths: An incredible versatility and an unique density of technology offer – paired with experience and technical knowledge of our well-trained employees. Our LernFabrik is evidence for consistent training and education schemes for our staff. 12 workcells guarantee the entire machining under one roof. Integrated system solutions complete the manifold programme with big advantages for our customers. It basically applies: Together with our customers we look ahead. Our customers benefit from the consolidated knowledge we established for years. We utilize our synergies and thereby extend your lead in market together. In collaboration our 3-F-formular applies: far – flexible- fair Our ambition: - best partnership - a long lasting, successful collaboration with all of our regular customers - discretion and exclusivity agreements if desired - mutual esteem and ethical behaviour Our motivation is the satisfaction of our customers.

Founded

1947

Employees

200 - 500

Certifications

Leutenbach Nellmersbach

Germany - 71397

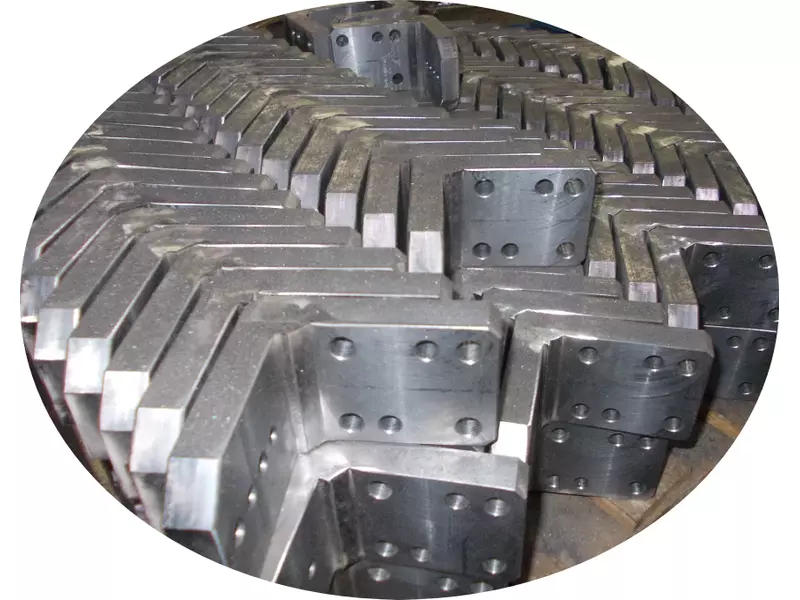

CNC contract manufacturing for tool, machine and plant construction. Do you build tools, machines or special machines? Do you need precision parts for your machines and systems? We take over the CNC manufacturing. Contract manufacturing for mechanical engineering, tool making or mold making. Take a look at our manufacturing examples! We manufacture highly efficiently on modern machining centers quickly with high quality and on time. Leading machine manufacturers have been relying on our production since 1989.

Founded

Employees

Certifications

Vrnjacka Banja

Serbia - 36210

CNC contract manufacturing, welding assemblies, individual parts, serial parts ORGANIZATION PLACE: GERMANY- Order logistics and deliveries through our own group transports up to twice a month. Goods are delivered with a German invoice, without further or hidden costs. PRODUCTION LOCATION- Bosnia and Herzegovina, EX-YU Läder MANY POSSIBILITIES- We combine our own production with our subcontractors' capacities in a pure source. Parts are carefully checked and only then delivered! STORAGE- In Germany (75417 Mühlacker) we can store any batches in advance, check them again and deliver at short notice! EXPERIENCE- Long-standing (over 20 years) experienced employees in various manufacturing processes. We have been delivering to our German customers for over 5 years. RESPONSIBILITY- Goods we deliver are insured, but we always accept sensible complaints and find a solution that suits everyone! Over 30 companies in Germany procure goods from us. POSITIVE THOUGHTS - our customers are slowly becoming our personal friends! Working with friends is fun, security and trust.

Founded

2020

Employees

< 5

Certifications

Mühlacker

Germany - 75417

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our Products: Naturally good. What make the nature, is a marvel. It produces perfection in every detail - timeless beauty, impressive refinement and sophisticated functionality - and churning. We of NC technology have made us this principle to the principle. With success. Due to the ever-growing demands, we have developed into a well-known provider of simple to highly complex machined parts. Many of our tasks come from highly-sensitive sectors (medical, military, Sensor technology, etc.). Through a widespread awareness of quality we achieve an above-average customer satisfaction. We achieve the high quality goals by an experienced team of qualified staff in conjunction with a progressive and modern machinery. Our offer for you ranging from raw material purchasing to the surface treatment to assembly production.This bandwidth has in the many years of our existence Customers from all sectors convinced. Fast. Innovative. Dependable. We look forward to meeting you. We pay attention to the finer points. Not only during milling. The delicate manufacturing in the milling requires maximum precision, not only in the production phase, but far beyond. All job steps must be coordinated with each other efficiently - from inquiry to delivery. Complex individual parts, small series, series and sample parts are manufactured in almost all materials (eg, titanium, aluminum, copper, industrial plastic, brass, cast iron, steel, etc.). The devices for processing customer parts we design and manufacture completely in our house. This is always done in close cooperation with our customers, as their specific requirements and our solutions are inextricably linked. The requirements of our customers, we solve with innovative technology, know-how and a high level of commitment. Not only our equipment up to the machinery meets the highest demands. Our employees also take part in regular training and further education and are therefore always up to date We you have the right machine an order.. Size, diversity and modern equipment of our machinery to ensure that NC art for many years meets the highest customer demands. Quality, accuracy and timeliness are guaranteed for each production size and any scale of production - from single pieces, small series and assemblies up to series production.

Founded

1980

Employees

10 - 20

Certifications

Dietingen

Germany - 78661

Dear business partners We present company Project Solutions doo from Bosnia and Herzegovina, which as supplier of metal parts in the field of machining. We sell our products in the countries of Western Europe that we list: Austria, Germany and France; The products are delivered to the customer's address during transport. The business activity of our company is based on the technologically supported and flexible delivery of components according to the requirements of the customer, which are used as components of machine assemblies in various production areas. We deliver parts for our customers: CNC turning, CNC milling, CNC grinding and heat treatment Our technical team is constantly striving to optimize the technology used to manufacture your components. what the use of special cutting tools own production and detailed process planning ensures optimal quality and best delivery price. We are a specialized production and service company in the field of supplying parts with low, medium and high technological level. By working with a broad portfolio of business partners, we can adapt flexibly to the size of the series (we can offer quantities of: one piece, so that very high serial numbers are possible). With this letter we would like to invite you to show us your esteemed trust and to recognize us as a partner who can deliver high quality parts, fast delivery and optimal costs. If you are interested in working with our company, we would be happy to visit you and introduce you to our options. In the attachment to the email, we will send you a script that describes our business activity in great detail

Founded

2009

Employees

20 - 50

Certifications

Gradacac

Bosnia & Herzegovina - 76250

POLTECH OTOMOTIV is a family-run company based in Istanbul/Bursa. As a supplier for well-known customers, we have specialized in the manufacture of complex turned and milled parts. Laser or plasma cuts? No problem! On request, we can even laser the product number onto your component. Our top priority is customer satisfaction. We trump with quality, price, organization, complete customs clearance and meeting deadlines. No hidden costs, no loopholes. Honest and authentic. You ask, we calculate, you decide. Our German-speaking contact person based in Germany ensures smooth communication.

Founded

2020

Employees

10 - 20

Certifications

Osmangazi

Turkey - 16190

Committed to providing our clients with high-quality, made-to-order machined components, MDG International has the expertise and technology to produce custom manufactured parts in a wide variety of shapes, sizes, or materials. Meeting the needs of diverse industries, our shop is well-equipped with top-of-the line CNC turning and milling machinery capable of holding precision tolerances down to. Our CNC turning machinery possesses magazine auto bar feeders and can manufacture parts measuring up to 60mm in diameter and 600mm in length. We can also chuck individual work pieces measuring up to 350mm in diameter.

Founded

2012

Employees

50 - 100

Certifications

Vogosca

Bosnia & Herzegovina - 71320

Sheet metal specialist Blech Berma is an all-round provider for sheet metal and lightweight construction from prototypes to medium series. The production of our core consists of laser cutting, punching, folding and welding. We also offer many auxiliary processes such as spot welding, rolling, inserts, saw grains and drums. Berma is also a real all-rounder when it comes to materials: from 0.5 to 12 mm, steel or stainless steel with brass or up to pre-painted plate, Berma has experience and in most cases also at home. We also handle a lot of pipes, tubes and profiles. Because we, we cannot have a wide range of products for our customers specializing in a limited number of operations or certain materials. That's why Berma Blech is your specialist for all-round sheet metal.

Founded

1986

Employees

20 - 50

Certifications

Bergeijk

Netherlands - 5571MX

Mould CAD / CAM Measurement Engraving Wage arrangements in the area milling, EDM and fairs.

Founded

1907

Employees

50 - 100

Certifications

Wendelstein

Germany - 90530

Founded

1993

Employees

10 - 20

Certifications

Düsseldorf

Germany - 40468

Welcome We see ourselves as an average modern operating company, based in Istanbul. Our company is working successfully in different industries (mechanical engineering, textile machinery, medical instrument industry, automotive industry, construction industry, graphic and optical industry, etc.) whose requirements are as varied as your products. In our mechanical production, we offer you virtually all machining manufacturing processes. Drilling, turning, milling and external cylindrical grinding in conventional production, milling and turning on modern CNC machines. That is our guarantee for your series production. With us you always get a completely finished product. Whether small series or prototype, whether raw or finished coating, whether or Kuststoff steel - all orders we finished quickly, reliably and accurately measured. Take advantage of our many years of experience and learn in the following pages to know our wide program. We are happy to await your inquiries and would be pleased if we could count you among our satisfied customers and your company. We support each other. The quality of our work ensured the success of our company. "Everyone is for each model, with production processes, each of the customer of the neighbor." About us The company Integral Makina sees itself with its long-standing and qualified staff as a traditional but modern positioned and competitive manufacturer of components for the Maschienenbau, Textilmaschienen, Medical Instrument Industry, Mechanical biomedical sector, automotive industry, construction industry, graphic and optical industry, etc. The technological requirements are determined by modern CNC machining centers. As the material in addition to steel and cast iron, aluminum, plastic and stainless steel, etc. is processed. Through close cooperation with companies from the region, we are able to manufacture complementary areas, suchEtc. to use as sheet metal processing (laser cutting), Hardening, Surface Finishing, external and internal cylindrical grinding, surface grinding, welding, assembly in a variety of ways and included in our manufacturing facilities. Customer-oriented quality assurance and on-time delivery are our determined measure of performance.

Founded

2010

Employees

10 - 20

Certifications

Maltepe - İstanbul

Turkey - 34843

Efe Lazer Makina has been working in the Machinery Manufacturing Sector since 2004. Efe Trading was founded on April 1, 2022 as a subsidiary of "Efe Lazer Makina" for the purpose of international sales. It has been offering laser cutting and bending services for the European market since 2022. Efe Trading is also active in gas, metal, argon and MIG/MAG welding. Our company, which has been committed to the principle of quality and customer satisfaction since its inception, has proven its consistency in the industry with its growing customer portfolio and customer satisfaction. Since 2022, it continues its services as Efe Trading with 70 employees in a 5000m2 closed area in Küçükbalıklı. Manufacture of food machinery advertising and signage industry branch of the mechanical engineering industry Heating, ventilation, air conditioning, mechanical engineering, elevator industry and automotive supply industry. It continues its services in the spare parts sector. As manufacture of laser cutting machines; Our goal is to become a leader in the industry be that integrates development technology into its industry experience without compromising the quality of our products and Sacrificing services means reliable, fair, honest, service-oriented and environmentally conscious.

Founded

2004

Employees

50 - 100

Certifications

Bursa/ Türkei

Turkey - 16250

"You have a task, TEPLAST the solution." As a problem solver for complex tasks TEPLAST has become known. We have gained this reputation is due to our team, our technical equipment and to the products, which manufactures this team. Highly skilled professionals provide at TEPLAST that our customers Touch ideas, see solutions that can sense the future. As a specialist for all engineering plastics for the areas Engineering Medical Laboratory Equipment Transport facilities we will solve all complex engineering tasks with plastics. Our other core areas are Acrylic glass processing for the shop and exhibition / display quality consumer products for the home Our focus is the production, processing and distribution of thermoplastics. TEPLAST (founded in 1994) has at its 5,000 square meters of floor space on one of the most modern CNC machinery in the branch.Our CAD / CAM systems allow users to produce customized and high-precision workpieces for the highest standards in the shortest possible time. Send your CAD data by e-mail or on a disk. We manufacture after your workpieces. Machining and processing of all thermoplastics (also transparent materials such as PMMA, PETG, PC), as well as phenolic resin laminated fabric. We use no epoxy hard tissue and no GRP plastics! In our business "Talva" we combine the machining of aluminum and stainless steel. Extract products: Screw conveyor Kiille Drive shaft pinion for roller chain Magnetic curve Hose Holder Gears and metering (PEEK) Funnel for coffee filling Conveyor star for ampoules Chain links for transport system Transport segments for ampoules filler Cap for laboratory equipment Letter Rack Lid for membrane pump Diadisplay Machine protection cover Brochure Stands Vacuum lid Use shelving system Cam guides / guide rails Dosier-/Förderschnecken extruded profiles

Founded

1994

Employees

100 - 200

Certifications

Ahaus

Germany - 48683

Precision of Function With our two product groups, we satisfy the highest demands on the precision and quality of our products and services. When compensating machine component tolerances, we provide specifi c solutions to enable fast and user-friendly working. As a manufacturer of laminated shims and a processor of various materials, we simplify working with tolerances. The M-Tech ® Product Group’s circle of customers encompasses large segments of industry, including the aviation and aerospace sector, drive systems technology and mechanical engineering. In addition to this, we develop and manufacture stamped and deep-drawn parts. Essential, expanded functional properties are achieved through complementary technologies, such as chip removal, welding, thermal and surface treatment and assembly. We have been supplying demanding areas of the printing machine, automotive and other industries for over 60 years. USP: In Germany only producer of laminated peelable sheets for tolerance compensation of component assemblies AND in addition high precision stampings. Technology short overview: - Stamping and deep-drawing - Chip removal - Assemblies - Precision stamping and cutting (0,025mm) - metal forming - CNC stamping - bonding - laminating - resistance welding Quality: DIN ISO 9001, DIN ISO 14001, DIN ISO 9100P

Founded

1945

Employees

50 - 100

Certifications

Dietzenbach

Germany - 63128

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

The PSFU Wernigerode GmbH is a family business with 30 years experience in high-precision machining. There are not many companies in Europe that can offer such a comprehensive solutions for the flat, circular and non-circular profile grinding. In addition to our high-precision grinding technology, we offer an extraordinary know how in the fields of 5-achsis-milling and precision turning. We are partner of the automotive and mechanical engineering industries. Our customers include Europe's most important automotive, printing machinery, medical and machine tool manufacturers. Universal CNC machining centers allow the production of various precision parts and guarantee flexibility and capacity for prototype, in the single-part and series production. A separate tool and fixture completes the service to our customers.

Founded

1992

Employees

100 - 200

Certifications

Wernigerode

Germany - 38855

Since 30 years we are now as a contract manufacturer for several companies in the Stuttgart region a reliable partner in the production of CNC turning & milling parts. This we offer our customers complete including all surface treatments etc.. In our department, milling, we can produce everything from simple 3-axis parts to complex 5-axis workpieces in batch sizes from 1 to 5000 pieces from a variety of materials. With our 3D CAD / CAM system, SolidCAM we can process almost all CAD format. Our Machine Shop manufactures parts of the rod to Ø60 including milling and feed parts to Ø350. The lot sizes range here also from 1 to about 5000 pcs Our ultimate goal is "100% quality & on-time delivery" at a fair price for both parties. After so long on the market, with to a large extent still the same customers as at the beginning, this intent seems to be so far we have succeeded. During this time, of course, is also the machinery and the number of employees has grown longer, why are we now and over this Internet platform in search of new customersMarkets. We will be happy to make you an offer or invite us to a to show you our production capabilities. We manufacture for you * Simple to complex parts * Small, medium & large series * Items & sample parts * Prototypes & assemblies From the following materials * Stainless steel, eg 1.4301, 1.4435, 1.4571, 1.4313 * Heat-treated steel & hardened steel, eg 42CrMo4 * Hastelloy 2.4610 * Tantalum * Titanium * Aluminum and brass and copper alloys * Plastics, eg POM, PVC, Teflon, PMMA * All construction and free-cutting steels, and more. All materials can be purchased and vice stamps of us with factory certificate to 3.1. The Umstempelerlaubnis TÜV Süd is available. In the dimensions * Milling - Max. X 800, Y 700, Z 600 * Rotate - Off the rack max. Ø60, min. Ø3 - In the feed max. Ø350, max. Length 500mm * Turn-Mill (from October 2011) - From the bar to Ø65 and Ø200 lining up on our new index R200 turn-mill center * Saws - Max.Ø410 We also offer * Wage laser labels * Complete machining - Mechanical mirror finish with Ra <0.5 - Glass bead blasting - Label by etching - Assembly of components - Design of parts and assemblies - Free-form surface milling with 3D CAD / CAM system - Quality control and documentation with measuring machine - Home delivery all the work that we can not perform even be awarded to competent subcontractors, such as - Cylindrical grinding - Erode - Surface finishes - Hardening - Electropolishing - Welding - Etc. Extract product: - Closing lid made of stainless steel 1.4301 - Part of a racing car-coupling of titanium - Base plate of a radiometer of AIMg3 - Diaphragm pump body made of tempered steel 1.6580 - Base plate in AlCuMgPb - Gearbox for electr. Car seats from AlCuMgPb - Test plug for a car seat made of POM - Counter-holder made of stainless steel 14571 - Valve guide made of stainless steel 1.4571 - Housing made of 1.2826 - Assembly of various materials - Shift gate for a passenger car automatic type: manual PVC - Pulley cutting steel - Mechanical part of 16MnCr5

Founded

1981

Employees

20 - 50

Certifications

Calw

Germany - 75365

Founded

Employees

Certifications

Westerheim

Germany - 72589

Officine Parolin is located on the North East of Italy. We employ 18 people and are specialised in the wire, tube, and stamped sheet processing. Our core business has been the welding since 1985. We mainly work on projects and drawings supplied by the customer. Our flexibility enables us to offer many sorts of customised products: from furniture, sport equipment, up to lightweight construction. We work the following metals: Steel, Stainless Steel, Aluminium. The cooperation with local partners grants us to supply the following services: painting, galvanising, sating, anodising and other surface treatments, laser cutting on sheets and tubes. The company is certified according to ISO 9001:2008 standards. Small quantities to process is not a problem for us!

Founded

1985

Employees

10 - 20

Certifications

RIESE PIO X (Treviso)

Italy - 31039

How can we help you? That's our way to say we are here for you to serve you as customer. Lentink founded in 1958 has grown into one of the leading suppliers in the field of high tech sheet metal. Deep drawing, pressing with transfers and progressive tools are our daily business. We deliver on daily base to our customers and we have to take care for more than 10.000 articles around Europe. With or without powdercoating and as simple parts and assemblies. Quality and reliability are our daily goals with our people. With over 60 years of experience, we manufacture large and small products in small and large series for different markets, sectors and industries in Europe. Companies like Bosch, Vaillant, Brötje and Buderus have also find their way to our company. This is facilitated by a wide equipped machine park consisting of-the-art technologies as well as by the daily commitment of more than 125 enthousiastic technical specialists. Processing of steel parts with many features and Lentink would like to advise you about your products as well. If you want to know more about sheetsteel possibilities; please feel free to contact us. Ronald Pool tel: 0031-611780352 WWW.LENTINK.NL Tel: 0031-315382130

Founded

1958

Employees

100 - 200

Certifications

Varsseveld

Netherlands - 7051 HP

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge