Machine moulding: receive an avg. of 7 offers per request

Discover specialized suppliers for machine molding on Techpilot. Our platform connects buyers with suppliers who use advanced molding technologies to manufacture high-quality cast parts. Use the e-sourcing process to find the best suppliers.

290 suppliers for Machine moulding

Filthaut: Everything from a single source. Most modern manufacturing facilities, decades of expertise and real passion for the craft of metal casting: Welcome Filthaut - their competent manufacturer of high-quality cast products. As a family run company with over 90 years experience in sand casting and lost wax casting, we have a right: the wishes and ideas of our customers, we count with an individual solution flexible, high quality and reliable from the first modeling to series production order. Our portfolio extends from modeling, through the industrial casting and plastic molds to the further processing of products. Translation by Google Translate

Founded

1919

Employees

50 - 100

Certifications

Iserlohn

Germany - 58640

Manufacturer of foundry pattern equipment Procurement of prototypes in aluminum, gray .Späroguss and steel

Founded

Employees

< 5

Certifications

Rickenbach

Germany - 79736

Welcome to Paun Parts, your dedicated global sourcing partner with our sales headquarters based in Stockholm, Sweden. We specialize in providing customized hardware solutions for startups worldwide.Whether you're at the initial stages of your journey or scaling up your operations we're here to support you every step of the way – from prototyping to mass production.Paun Parts is a global sourcing company specializing in manufacturing solutions of high-quality mechanical components crafted from metal and plastic.With partner factories strategically located in Europe and Asia we harness a diverse range of manufacturing solutions to meet your specific requirements. Let Paun Parts simplify your hardware procurement process allowing you to focus on what truly matters – innovation and growth. Partner with us today and elevate your startup to new heights in today's fiercely competitive landscape.

Founded

2023

Employees

5 - 10

Certifications

Kungsängen

Sweden - 196 41

We are specialized in the delivery of customized castings and forgings for OEM companies. From 1 large casting of more than 120 tons to for example series of 10.000 pieces of 25 grams. Mainly in ferro alloys, but also in aluminum, bronze and nickel alloys. All our major suppliers are in Europe, mainly South- and Eastern Europe, but for some exotic alloys and investment castings we have cooperation’s with foundries outside Europe. Our expertise is primarily in the maritime, offshore, chemical and mechanical engineering sectors, but also semi-conductor, utility, agriculture, truck and mining industry we are very familiar with. We even have customers like Shell. We are also able to help and develop a casting or forging from a previously welded structure; thus, reducing costs and weight. Alloys we supply are not only steel and ductile iron, but also wear-resistant white iron, duplex steel, manganese steel and so on. Based on 25 years of experience and a very extensive reliable network, we are able to find exactly the supplier with the right setup in production options, sizes and alloys, combined with experience in the type of castings you need. Thus, avoiding long learning curves or expensive learning lessons. We only do business with suppliers that we regular visit and inspect and can supply according to our highest quality level, on time delivery and still have a competitive price.

Founded

2009

Employees

< 5

Certifications

Sliedrecht

Netherlands - 3363 XB

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

YOUR SPECIALIST FOR ALUMINUM DIE CASTING! From development to prototypes to series production — with SANDER DRUCKGUSS, you get everything from a single source! In over 70 years, SANDER DRUCKGUSS has developed from a mixture of tradition and progress into a leading medium-sized family business. As a reliable production partner for complex machined cast and system components made of die-cast aluminum, we have made a name for ourselves particularly in demanding industries such as automotive and medical technology. Ever increasing demands on products, particularly in automotive and medical technology, have decisively shaped and developed the company in recent years. Our team of 70 motivated and qualified employees works passionately to cast aluminum die-cast parts and offer them from development and prototypes to series production and assembly. With our modern machinery and a strong emphasis on quality and technology, we offer tailor-made solutions that are precisely tailored to the needs of our customers. Our short decision-making processes and close cooperation with our customers enable us to react flexibly to requirements and guarantee the highest possible delivery and punctuality. Our comprehensive know-how ranges from tool manufacturing to series production of ready-to-install cast components. Our products, which we sell in Germany, Europe and partly worldwide, serve well-known customers from various industries, including: • Automotive • Home appliance technology • Medical technology • Electrical engineering • Building accessories • Mechanical engineering • alternative energy industry • alternative vehicle energy • and much more

Founded

1949

Employees

50 - 100

Certifications

Ennepetal

Germany - 58256

Zanardi Fonderie S.p.A. produces spheroidal ductile iron castings and austempered ductile iron castings (ADI) with a green moulding process. Production, which includes machining and austempering heat treatment, is located In our only plant in Minerbe (Verona, ITALY), which employs about 220 people, The production capacity is mostly oriented on medium size batches and the full annual capacity is about 22,000 tons, of which 10,000 in ADI, with a unit weight between 0,5 and 120 kg

Founded

1931

Employees

200 - 500

Certifications

Minerbe (VR)

Italy - 37046

Fonderia Persicetana has been working for over 40 years in the field of light alloy aluminium casting. The experience and the know-how accumulated over the years enable us to satisfy any market request, thanks to continuous investments and expansions aimed at boosting the production capacity and improving the technical quality.

Founded

1970

Employees

20 - 50

Certifications

SAN GIOVANNI IN PERSICETO

Italy - 40017

Our industry, Rei Tregi srl, has been manufacturing fittings, valves, taps for the civil and industrial use in the water – gas - marine - compressed air - fire protection and household appliance sector since 2000. Thanks to the long experience and know-how of the ownership, constant investments in modern technology, a professional team expertise, the UNI EN ISO9001 certification and strict quality controls, we are able to support our international partners throughout the entire production process (99% export). We are specialized in producing high quality customized solutions: we turn – forge/press – cast - machine from simple components to very complex ones in different alloys at very competitive prices (also plastic injection). They are produced with the specifications and drawings of our clients only. We have the total control from the raw material to the finished packed product. Our portfolio includes many European companies, also in your field , that have chosen us as trustworthy suppliers with long term cooperation relationships. On this page you find our company fact sheet and our brochure is available on our website: https://www.reitregi.it/en/ We would be pleased to speaking or meeting with you in order to analyze your Product needs. By sending your drawings and specifications we could quote you without obligation our best offer to let you verify our price/quality ratio. We look forward to receiving your kind feedback and have the chance to cooperate with your company in the near future. For further information we remain at your disposal and thank you for your kind attention Mit freundlichen Grüssen / Best regards / Cordiali saluti Silvana Martinelli Manager of International Customized Projects for Technical Metal and Plastic Components Rei Tregi Srl Via Neziole 3 25055 Pisogne (Bs) export@reitregi.it www.reitregi.it Mob. +39 393 811 5943 Ph. +39 0364 899020 Fax. +39 0364 86772

Founded

2000

Employees

50 - 100

Certifications

Pisogne

Italy - 25055

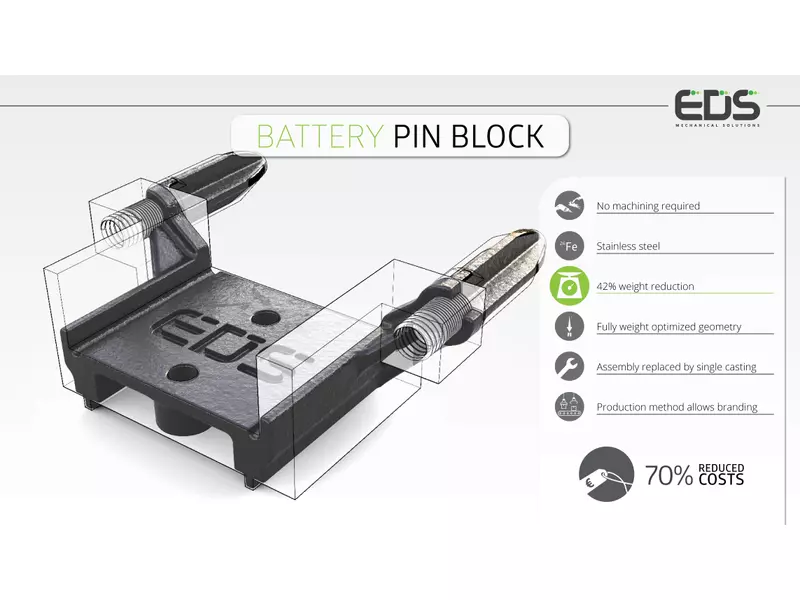

EDS stands for Engineering, Design and Supply of mechanical components which we have developed together with the customer. Our objective is to supply the developed components resulting in a cost reduction for the customer. We do so by looking at weight, assembly procedures, choice of material, load cases, machining and manufacturing process. We are not solely an engineering company nor are we a trader of standard parts. We are a supplier of components which we developed together with our customers and we are specialized in converting metal fabrications such as fully machined or welded parts into castings we can offer a global solution to our customers, and also we can make stock for our clients.

Founded

2015

Employees

10 - 20

Certifications

Amsterdam

Netherlands - 1101

LCN has a production area of 18,000 m² with a state of the art machinery park and infrastructure. Our dynamic team develops and manufactures premium quality products in close co-operation with our customers at our plant in Guadalajara, Spain (near Madrid) Fine Blanking Conventional Stamping Tube Cold Forming Rotary Swaging Axial Forming High-Performance Grinding Automated Welding Aluminium Die Casting CNC Machining Plastic Overmoulding Complex Assemblies Safety Critical Handbrake Systems Safety Critical Steering Systems Safety Critical Transmission Park Lock Systems

Founded

Employees

200 - 500

Certifications

Guadalajara

Spain - 19004

Presentation of the company The company METOS vos was founded in May 1990. As trading company of family type is active from the beginning, all in the field of metallurgy and mechanical engineering on a smaller area. There currently is METOS vos Chrudim a stabilized and closely technically oriented company that also represents foreign companies in the Czech foundry market. Furthermore, we deal with the sale of the pig iron, ferro alloys, castings with or without machining and further from the machine components for Czech and foreign buyers of series deliveries to piece deliveries. In cooperation with the company RTI, NOVA CAST, Koins, which we represent, we handle technical support and service activities mainly in the field of casting metallurgy, and in the technical preparation of production from casting. We have a stabilized and skilled community of 12 employees in the foundry industry and mechanical engineering. 1 Annual turnover: 3.2 million EUR in 2005 2006 EUR 5.1 million 2007 4.35 million EUR 2008 3.75 million EUR 2 We deliver to: * Castings from GG 15, 20, 30 - GGG 40.3, 40, 50, 60 - Cast steel and malleable - Aluminum, brass, bronze * Sand casting, investment casting, Kokielenguß * Pattern equipment, dies and molds * Cast iron - Sorelmetal * Ferro-alloys * Machining of castings and weldments 3 We are an agency or Seller from the following companies: * ABM Foundry Engineering GmbH Germany - untouchables molding plants Haflinger * Rio Tinto Iron & Titanium Inc. Canada - pig iron, Sorelmetal * Allied Mineral Products Inc., USA - Refractory materials * Nova Cast - Sweden - Nova Flow & Solid, THERMAL analysis * Koins - Sweden - laser controlled casting machines, crushers * Snam Alloys Pvt. - India - Ferro Alloys based on FeSi inoculant for ductile iron and Lamelengraphit, FeSiMg for the treatment of cast iron with spheroidal graphite 4Among the most important customers of our company include: * BLITZ M. Schneider GmbH, Germany - edited castings * Gebr Rehbein GmbH & Co, Germany - castings * G. Schwepper fitting GmbH & Co, Germany - castings * IbH GmbH, Germany - machined castings * INKOMA GmbH, Germany - castings * Pintsch Bamag GmbH, Germany - castings * QUEINS & Co. GmbH, Germany - machined parts * ABM Foundry Engineering GmbH, Germany - welded parts 5 For our customers we can also offer the following services: * Acquisition of documentation and their transfer to Czech standards and delivery for Czech producer * Solution of the production of pattern equipment, sampling, standard deliveries and processing at a suitable company * Choosing the best manufacturer for the particular case and organizing transportation, including customs clearance 6We are equipped with: * 3D CAD system SolidWorks * Software NovaFlow & Solid for the computer simulation of form filling, etc. Gußersterrung * Calculator with 8 gigabytes of RAM, 64 bit Windows Professional For our customers, we are a supplier with full responsibility for the quality and delivery dates given in accordance with the contract delivery.

Founded

1990

Employees

Certifications

Chrudim

Czech Republic - 53701

Today the TROMPETTER GUSS GmbH & Co. KG is one of the modern foundries Bavaria and counts well-known companies to your customers. On two molding plants, the company produces high-quality components made of cast iron with lamellar graphite and ductile iron in small and medium series for the general machine industries, the areas drive technology, fittings and textile machinery, shipbuilding and in agriculture and Baumaschinenbau. Translation by Google Translate

Founded

1946

Employees

100 - 200

Certifications

Bindlach

Germany - 95463

Iron Foundry GJL and GJS BENODUR ADI SiMo Hand and machine moldings

Founded

1996

Employees

100 - 200

Certifications

Uzwil

Switzerland - 9240

More than 100 years of experience - this is our strength! As early as 1903 was cast by the brothers Not for the first time at this location in Schönheide. In 1993 the company was privatized and founded the Schönheider Guss GmbH. Our traditional company specialized in the areas of electrical engineering industry and general mechanical engineering. Orders from other industries are also manufactured.

Founded

1993

Employees

50 - 100

Certifications

Schönheide

Germany - 08304

DSP ALU GmbH works with various manufacturers who offer very high quality products at very competitive prices. These manufacturers produce with modern machines and qualified and experienced personnel. The suppliers are prepared to take on the initial investment and control themselves and go into production after positive tests by customers.

Founded

Employees

< 5

Certifications

Bonn

Germany - 53125

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We manufacture: Ductile iron according to DIN EN 1563 Ausferritic ductile iron (ADI) according to DIN EN 1564 Silicon and molybdenum alloyed ductile iron Cast iron with lamellar graphite according to DIN EN 1561 White malleable according to DIN EN 1562

Founded

Employees

Certifications

Schmiedeberg

Germany - 01762

tooliss gmbh is a globally operating technology company specializing in engineered plastic parts and castings. As a highly specialized engineering service provider, the company uses value analyses to develop solutions for their customers that are optimized in terms of technology and cost-effectiveness.

Founded

2005

Employees

Certifications

Urbach

Germany - 73660

“DIKS-METAL” LТD was established in 1999. At the beginning its main activity was trade with home production and imported metals. At the moment the company occupies field of engineering and production process. We have our own production capacities and storehouse. Our team is build from highly qualified experts. Their wide background in the field of machine-building gives us opportunity to work on composite projects with higher level of complexity. Company production stands well on Bulgarian and international market. We are glad to have special interest on cranes and their elements, equipment for transport systems and non-standard equipment from different character. Our constant customers are companies in the field of energetic, mine-extraction and metallurgy, such as Steam Power Plant “Bobov Dol”, Nuclear Power Plant “Kozloduy”, Water Power Plant “ Energomontaz”, etc.

Founded

1998

Employees

5 - 10

Certifications

Pernik

Bulgaria - 2300

Our company is a reliable supplier for companies who need castings as raw or machined.Our product range includes the following materials: Grey cast iron, Ductile iron, steel casting for wear applications such as manganese steel casting unalloyed, low-alloy and alloy steel casting parts. After 15 years foundry experience we were able to add value to casting parts. According to need of customer, we can supply parts with added value this means; we can make additional operations after casting such as turning, machining, milling, assembly, Heat Treatement, Coating. Our group consists of one export company (An Dış Ticaret) and two foundries, which specialize in cast iron and cast steel. Both are ISO 9001 certified. Our foundry equipment consists of a medium-frequency induction furnace with a capacity of 500 Kg/hour. In addition to hand moulding we also use the shell moulding process for precies surfaces. Cores are produced by shell moulding process and by a CO2 (aminegas) core machine. Our foundry is speacialized on hydraulic parts,valve parts, machine parts,tool parts and wear-ressistant cast steel. Our sales to Europen countries, Russia, United Kingdom, Austrlia, Canada, South America and United states is annually around 1.200.000 €

Founded

2017

Employees

20 - 50

Certifications

konya/Türkei

Turkey - 42050

We want to be a reliable partner for you As the only foundry in Switzerland, we supply both aluminum, ductile, gray, steel, copper and investment casting in lost wax, raw or ready for assembly, with or without heat and surface treatments. In close cooperation with our customers, we manufacture the most modern facilities cost-effective quality products. Sophisticated semi-finished products are our strength.

Founded

1886

Employees

50 - 100

Certifications

Oberburg

Switzerland - 3414

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge