Mechanical assembly: receive an avg. of 7 offers per request

Discover specialized suppliers for mechanical assembly on Techpilot. Our platform connects buyers with suppliers who offer comprehensive assembly services for mechanical components. Use the e-sourcing process to find the best suppliers.

2543 suppliers for Mechanical assembly

For 35 years we have been producing quality that flies! Our high-end production parts are an integral part of the aerospace industry. We are also at home in the field of medical technology and create a perspective for our customers here. In addition to the classic production of high-precision parts - often with special materials such as Invar, Kovar or Inconel - our own engineering subsidiary offers custom-made special and automation solutions for the highest demands in many industries. After two generations in family hands, the Meidlinger Group passed into new, responsible hands at the end of 2020 and the upheaval for a new future was initiated.

Founded

1985

Employees

50 - 100

Certifications

Brackenheim

Germany - 74336

Founded

1946

Employees

50 - 100

Certifications

Ennepetal

Germany - 58256

Philosophy LST is your highly specialized service with sheet metal We cut and join sheet metal in all common and unusual variants - quickly and accurately. Our expertise in all aspects of laser cutting technology makes us one of Europe's largest providers in the laser processing of sheet metal components. The basis for this outstanding market position consistent focus on the laser technology. So we are able to flexibly respond to all customer needs: technological and responsive. Following the motto "flexibility by size", we can also achieve very short-term customer needs. This is made possible by two factors: by machinery, which always represents the most advanced state of development. The joint development of laser cutting machines together with the leading manufacturers in the industry is just one document. our know-how: Only with our staff, their expertise and commitment we can consolidate and expand our market leadership. Therefore, the permanent training and training of our team major concern and an essential part of our performance. Services High-precision, fast and flexible. Laser technology offers us for processing of sheets of steel, stainless steel and aluminum almost limitless possibilities. Cut with the latest laser technology, or we combine plates: high-precision, fast and flexible. Whether moldings or flat boards from prototype to series production - we will implement your specifications. And always at the highest technical level and with the fastest response times. With our know-how and our experience we support and advise you competently in the millimeter-exact implementation of your projects and ideas. In addition, you can use our know-how for the laser contract manufacturing. LST is based on the following procedure: 3D laser cutting 3D laser welding 2D laser cutting Assembly production Tube and profile processing For further questions, our consultants are happy to help.

Founded

1988

Employees

200 - 500

Certifications

Hövelhof

Germany - 33161

Our company is specialized in sheet metal processing for 20 years suppliers. We deliver the item to complete assembly of components including chrome steel, aluminum and steel. Laser Cutting - Punching - Bending-Gehäusebau robot welding of steel and aluminum

Founded

1994

Employees

5 - 10

Certifications

Wiler bei Seedorf

Switzerland - 3266

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

About Us We are happy to introduce you to our company: The Ackermann CNC-Technik GmbH is an owner-managed, medium-sized company with headquarters based in Southern Freiberg am Neckar. Our production program focuses on turning, milling and drilling parts in medium and large series. Our years-coordinated and motivated manufacturing team can draw on the latest CNC technology. Our work and study plans, as well as modern measurement technology, help our quality of thought, to a documentation and reproducibility on operation level. We are supported which ensures our PPS system for comprehensive transparency of all orders and appointments on a commercial and productive level. We are proud to be able to the great Swabian automotive manufacturers, as well as their key component suppliers are among our clientele. Our own products With the vacuum clamping systems, the dividing heads and the Fasfräsern which continuous Learn further, we were able to advance in this sector in recent years become the top provider. o Vacuum Clamping Technology With our vacuum clamping systems, we have almost all materials under control. This enables components quickly, safely and gently fix. Even thin-walled parts can stretch without distorting. Whether milling, grinding, engraving, printing, lasers or fairs, our vacuum clamping systems have in any case some of the arguments for themselves. Special solutions are here everyday and can be implemented quickly and economically. The increased non-magnetic tensile parts (the common materials tend more and more towards aluminum, stainless steel and plastic) have contributed here your part. A sophisticated range of accessories makes from any standard disk, a custom chip solution and provides the customer a high level of investment security. o vice dividing head Flexible solutions in the areas of milling, grinding, washing and measuring. Simple, secure and above all accurate clamping and alignment of parts.The clever collet holder which the standard collet types of machine builder uses unique. No additional fixture costs for the customer. Short set-up times by the inclusion in the vise are best argument especially in individual production. A "real" additional axis. (If the state of Bavaria honored as an outstanding invention "Bavarian Innovation Prize 1998") o bevel cutter The most rational solution for chamfering tools, our patented bevel cutter. Instead of buying a lot of expensive special cutter (angle), our customers can select the desired bevel angle on the Ackermann-bevel cutter and place in a very short time its required chamfer on the workpiece. The optimal solution for sample, prototype and tooling. A deep range of bevel cutter upgraded here for every eventuality. All these products are used in own our own manufacturing your use. For this reason, the further development and application consulting customers are practical and sustainable. This competency package we are today in many industries as by TÜV Süd according to DIN ISO 9001-2008 certified A supplier in ongoing business relationships.

Founded

2005

Employees

20 - 50

Certifications

Ditzingen-Heimerdingen

Germany - 71254

We design and manufacture hydraulic components from stainless steel and plastics for use in devices of high purity water, media supply and concentrate preparation for medical technology and pharmaceuticals. We offer complete solutions from a single source - from conception through samples and mass production to assembly of the finished components. Our scope of activities includes: designing, prototyping to series production of individual components and machines. To ensure the highest quality standards, we are constantly investing in the latest manufacturing methods in our machinery, as well as the development of our employees. Also, a flexible, precise mode of production, as well as constant internal quality control and external monitoring by independent testing institutes, contribute to a high level of product quality and satisfied customers. Our company is in accordance with DIN EN ISO 13485:2012 VDE certified

Founded

1990

Employees

50 - 100

Certifications

Hösbach

Germany - 63768

MegaPlast GmbH was founded in 1991 and is your reliable partner for injection moulding, mould making and prototype construction. With competence, experience and motivation, we can offer our customers everything from a single source, from conception, prototyping and tool making to series production. We manufacture for you in 1- and 2-component technology, hybrid components on 37 injection moulding machines. ARBURG and DEMAG machines with clamping forces from 25t to 350t are available to meet customer requirements. Dealing with stack and multifunctional moulds and their careful care is a constant practice and thus a prerequisite for components of the highest quality. Our tool shop has an efficient machine park with which we manufacture injection moulding and punching tools from aluminium or steel. The quality of an injection moulding tool has the highest priority in order to guarantee a proper high-quality injection moulding. We achieve this quality with experience, know-how and modern machines. Our tool shop is supported by the CAD/CAM program SOLIDWORKS/SOLIDCAM. We work and act according to DIN ISO 9001:2015 in order to achieve our quality goals in the long term. Furthermore, we are able to measure components optically and tactile 3D at any time with the help of our WERTH measuring machine and our 3D scanner. Furthermore we are able to create a reverse engineering. Also an EMPB or PPAP creation according to VDA is no problem. Our range of services: - Construction Solid Works - Production of cast components from PUR & nylon with corresponding property modifications - mould making - Toolmaking from aluminium and steel - gauge construction - CNC milling of metal and plastics - CNC fairs - 3D printing for metal and plastic materials - Injection moulding production up to mass production on currently 38 machines up to 350 tons - Tampon and screen printing With our machine park in the production with 36 injection moulding machines we are able to process technical plastics, e.g: PA, ABS, ASA, PC, POM, PE, filled or unfilled and coloured according to RAL as well as crystal clear material PMMA. We also process elastic plastics (rubber).

Founded

1991

Employees

50 - 100

Certifications

Steinbach-Hallenberg

Germany - 98587

Welcome to GISSLERprecision – Your specialist for Precise Metal Production Since 1986, reliability and security in precise metal production has been our business. We are passionate about producing high-precision metal parts and components which deliver a high performance worldwide – our name stands for optimal quality. We offer the entire value chain from one source: - Material procurement & scheduling - Complete fabrication with surface treatment and labeling - International logistics with storage and safety stock We aim to meet all requirements following our high standards regarding reliability, punctuality and quality. This makes us an esteemed partner for our clients in the automotive industry, drive technology and machine building industry. Repeated certifications according to ISO 9001 and ISO 14001 standards as well as the processes in accordance with the standards of ISO/TS 16949 testify to the high importance we place on quality and environment. As highly innovative producers with technical know-how, we manufacture precision turned parts, (turned) milled parts and grinded parts in large or small production - find out for yourself! Made in Germany - Made by GISSLERprecision High precision turned parts With a total of 20 CNC-controlled lathes (partly double spindle machines) in bar and chuck machinery, we offer the complete range of machining in the field of turning. We produce high precision turned parts: for bar processing with diameters ranging from 20 to 100 mm, for chuck parts with diameters ranging from 20 to 350 mm. Some of the lathes are equipped with powered tools (1 to 3 revolver with Y-axis) to produce complex components for our clients in the automotive industry, drive technology as well as in mechanical engineering. Our machinery is characterised by its versatility. This ensures our ability to deliver even in case of bottlenecks and to ensure the supply of parts to our customers. One of the focuses of our range of parts lies in the serial production of complex parts. As a supplier, our state-of-the-art tool management helps us to compensate tool failures immediately. Heat treatment or surface refinement at partner companies certified according to ISO 9001 can be carried out at the customer’s request to complete the machining process. High precision (turned) milled parts With high precision and high efficiency multi-axis turning centres with 1 to 3 turrets and 1 to 3 Y-axes, we are able to produce high precision (turned) milled parts with driven tools. Depending on the requirements, we use specially manufactured form milling cutters through which the workpieces come close to ground surfaces in terms of accuracy, tolerance and surface roughness. Our gear milling activities: external and involute gearing (up to module 6) as well as spur gearing and serration. We process various types of materials, i.e. all current standard and quality steels as well as aluminium, cast iron and non-ferrous metals. High precision grinding parts Our machinery enables us to carry out all kinds of grinding work in the following areas: ◾ External cylindrical grinding up to diameter 450 mm and lengths up to 1000 mm ◾ Internal cylindrical grinding up to diameter 150 mm and lengths up to 150 mm ◾ Flat grinding up to a length of 500 mm, width of 250 mm and height of 200 mm High-precision gearings ◾ External gearing / involute gearing (up to module 6) ◾ Spur gearing / serration High precision laser marking Our contactless laser marker marks surfaces on an area of 110 x 110 mm with text, logo, serial number or graphics (Data Matrix™, QR codes, barcodes). Complete assemblies We provide comprehensive solutions and even fully assembled component groups,

Founded

1986

Employees

50 - 100

Certifications

Zell a. H.

Germany - 77736

MediKomp From technical advice on the development and design to series production. With over 320 employees MediKomp stands for competence in terms of stainless steel. Item production, assembly-ready components or complete assemblies: We offer individual solutions in medium-sized batches. Benefit from our expertise Customers in the following industries: - Mechanical Engineering - Medical - Refrigeration and air conditioning technology - Vehicle - Architecture and Design - Food industry - Machine tools - Pharmaceutical industry - Computer Industry - Electrical Engineering - Laboratory and Analytical Techniques Sheet metal processing With our modern sheet metal working machinery, we offer this comprehensive technical processes - Laser cutting - Stamping - Embossing - Deburring Machine - Edge - Bending - Forming Machining Our modern machinery from over 40 CNC milling and turning centers is the backbone of our machining.In addition, complementary technologies such as honing, flat and cylindrical grinding. The programming of the individual machines via a central programming system in order to realize your ideas quickly. Processed materials: - Stainless steel - Aluminium - Brass - Steel castings Surface Technology High-quality and homogeneous surfaces to customer requirements! MediKomp offers a variety of possible surface variations such as: - Glass bead blasting - V-2A-rays - Grinding - Powder coating - Wet varnishing - Electropolishing Welding Approved quality! Our welding experts are consistently trained and checked on a regular basis: so that every seam is sitting! In over twenty individual welding booths all common welding processes are used: - TIG - MIG - MAG - E-welding - PPAW (powder plasma) - Resistance welding - Spot welding - Stud Welding - Laser Welding Prototyping According to your ideas, sketches or drawings we design and manufacture from concept design to series production: prototypes, first samples, custom made, test samples or pre-production parts as individual parts, assemblies, or as complete products includingElectronics. We provide quick solutions here by rapid prototyping of plastic (ABS, FRP or CFRP). Assembly Based on our years of experience with the assembly of medical products, also including electrical components, we assemble your products according to your wishes and demands! From simple assembly through to the fully assembled high quality OEM product: We will deliver your product in the best quality!

Founded

1999

Employees

200 - 500

Certifications

Rastatt

Germany - 76437

Our services are: Consultancy in project development Construction of the tool, Mould Plastic molding Component manufacturing Ultrasonic welding Assembly of components Our production is certified according to DIN EN ISO 9001:2000 by the PÜG.

Founded

1972

Employees

Certifications

Binzen

Germany - 79589

Welcome to Neubeck CNC - technology! Our workpieces are aesthetic as art pieces, individually as works of art and accurate as you would expect from a powerful suppliers. Learn the company Neubeck CNC - know technology as a reliable partner. Quality and flexibility combined with an attractive price are very important to us Specialty: CNC - Milling: The company Neubeck CNC Technology specializes in CNC milling of small parts. Surface Finish: Of course parts manufactured by us are provided on request with a surface finish. We barrel finishing (vibratory finishing process), grind or anodize according to your requirements. Modules: We can complete the parts we to assemblies. We will take care of procurement of materials and installation. We also have several years of experience in the processing of Plexiglas (milling and gluing).

Founded

1988

Employees

5 - 10

Certifications

Dorfprozelten

Germany - 97904

The Industriedreherei Dobirr made since 1996 in many industrial areas such as special engineering, equipment manufacturing, general mechanical engineering, as well as for the device and Toolmaking. With our diverse and extensive range of machinery we meet with security and your requirements. If we do not meet your needs, we are ready to invest in new production facilities. With a staff of young and mutivierten employees, we are very flexible and we can in the shortest time on task setting. In 2007 and 2008, investments were made in new, modern lathes and milling machines to meet the complex requirements of our customers. A comprehensive quality control is, of course, and meets the expectations of our customers. Single and serial parts of our production are manufactured according to drawing, sample or technical drawings. For the tool, we made in 2D and 3D programming electrodes, parabola and models.

Founded

1996

Employees

10 - 20

Certifications

Stuhr

Germany - 28816

We provide complete solutions of systems and devices (with and without structures), tools (sheet metal stamping) and test gauges and special machines of all kinds On our Tebis 2.5 and 3D programming courses, we can create all the editing programs. 2.5 and 3D machining also be run as subcontracting. The mechanical and spatial possibilities for the manufacture and assembly have since been expanded as the know-how. Further, huge investments of new production halls, crane systems, large CNC - controlled milling machines and Horizontalbohrwerken paved the path challenging as an interesting partner to the automotive industry, the press industry and the aerospace technology. Everything from a hand- Hydraulics, pneumatics and electronics round out our catalog of manufacturing options.

Founded

1969

Employees

20 - 50

Certifications

Hardthausen-Gochsen

Germany - 74239

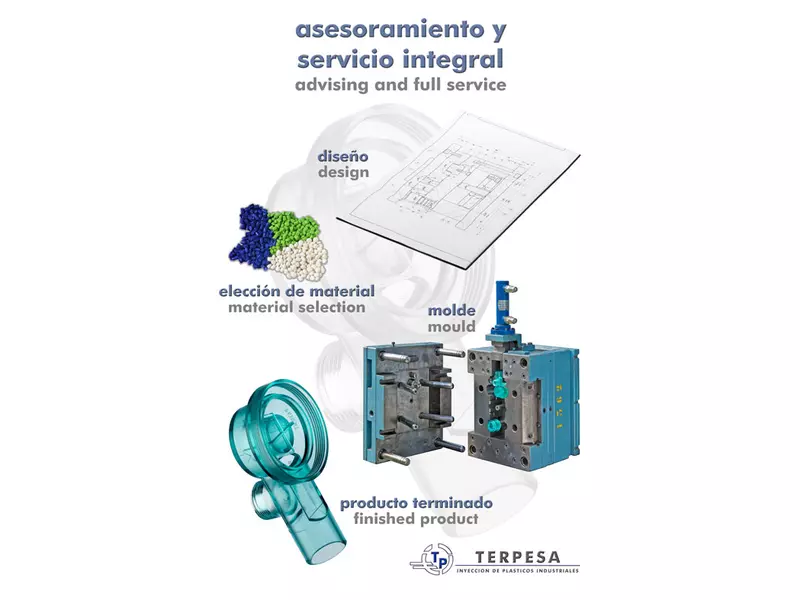

Manufacturers of plastic injection molding parts on demand, family business, specialised in technical materials such as PMMA, PC, PVDF, PEEK, PFA, PSU, PA (6, 6.6, 11, 12, 46), POM, PPS, TPV, SBS, BIO, .. Our machinery clamping force runs from 40 up to 550 tons. We can also provide design service, mold manufacture and thermoprinting.

Founded

1982

Employees

5 - 10

Certifications

FUENLABRADA - MADRID

Spain - 28946

The metaform machine parts GmbH is a cross-industry manufacturing specialist in the field of metal cutting. Our team of approximately 50 people consists almost exclusively of Trained personnel

Founded

1993

Employees

20 - 50

Certifications

Frankenberg

Germany - 35066

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1977

Employees

200 - 500

Certifications

Sinop

Turkey - 57000

In 1949 the company started under the name of MAS as a rental station for equipment, the repair and instant reduction of Landmaschinen.1962-1983 The MAS strengthened its good position even further and took over plus overhaul LKW.1983-1991 The repair was adjusted , Similarly, a production line for packaging machines was built. From 1990, under the name Namag GmbH.1992 Acquisition by Dechamps group and under a new name in 1994 in engineering and Formkastenbau active. By purchasing the field of activity extended also to hydraulic components. The sister company Bucher Hydraulics (formerly Oelhydraulik Altenerding near Munich) sold its shares in 2013, so that the NAMAC Maschinenbau GmbH & Co. KG from then on, there is an independent company in the market.

Founded

Employees

20 - 50

Certifications

Naumburg

Germany - 06618

High quality standards and satisfaction of our customers are looking for us again and again spur forward-looking, more effective ways and are relative to optimize our products processing, reliability and functionality. It is constant contact with customers and users of the engine of our innovative development work, which is documented impressively in the extensive production program of Erchinger MedTechnology.

Founded

1949

Employees

20 - 50

Certifications

Tuttlingen

Germany - 78532

Nedimpex Mij BV is supplier of constructive parts. We supply different kind of turning & milling parts, welding & construction parts, sheet metal cutting & bending parts, castings incl. several. surface treatments. We combine our knowledge and experience with a wide range of technological production possibilities. We deliver high-quality products at a low cost price and short delivery times. We work together with Nedimpex Products BV for the assembly of components and semi-finished products.

Founded

1993

Employees

< 5

Certifications

Dronten

Netherlands - 8253 RA

Kiefer GmbH has been producing stamped and bent parts as well as welded constructions of the highest quality for more than 35 years. Our components are used by well-known customers in the automotive, building hardware, sanitary, household appliance and solar industries. With a constant focus on efficiency in all production steps, we are able to deliver the highest quality standards at unbeatable prices. We work steel, stainless steel, light and non-ferrous metals as well as plastics up to 15 mm thickness on modern and efficient machines. Our in-house tool shop allows us to quickly and professionally realize even short-term orders. Technical Equipment: - 2 punching machines - 35 eccentric and hydraulic presses with up to 400t pressure capacity - 4 multi-spindle drilling machines - Thread cutting machines - 8 welding workstations (MIG, MAG, TIG and resistance welding) - 2 welding robot systems - 2 high performance metal sawing machines - Own toolmaking

Founded

1983

Employees

50 - 100

Certifications

Biedenkopf

Germany - 35216

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge