Plastics rubber plastic processing: find suppliers

Discover specialized suppliers for plastics and rubber processing on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to manufacture high-quality plastic and rubber products. Use the e-sourcing process to find the best suppliers.

1396 suppliers for Plastics rubber plastic processing

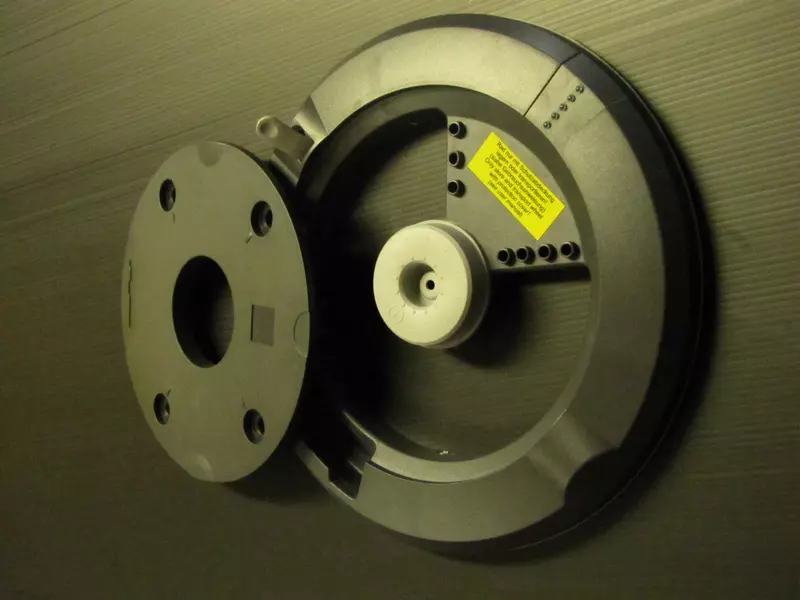

We are a team of professionals specialized in plastic injection able to make your project a reality, striving always for the quality price ratio, and keeping as important pillars the innovation and efficiency, ensuring your success and our market position. Our quality, competence, experience and ease of communication in languages such as English, French, German and Spanish has gained the trust of major international companies. We operate as a multidisciplinary team of high performance that celebrates the success and aspires to reach new heights. The solutions we develop are used in various industries such as home appliances, electronic, medical, food, packaging and industrial where we have a high experience. Our development and production of thermoplastic components have a recognized quality management system in compliance with the standard UNE-EN ISO 9001: 2008. Our culture of excellence is reflected in our procedures that follows the highest industry standards and are continuously monitored and improved. Our customer satisfaction results are an example of the confidence that they deposit in our company.

Founded

2010

Employees

20 - 50

Certifications

Santo Tirso

Portugal - 4780-162

Meislitzer Präzisionstechnik mainly produces customer-specific single components as well as prototypes and small batches for existing customers from a variety of industries including machinery and plant engineering, automotive, electronics, semiconductor, energy and medicine. Our employees are highly experienced in working with a complete range of specialized materials such as tool steels, carbides, synthetic materials and ceramics and have mastered many quite tricky manufacturing challenges so far. The combination of accuracy, speed in response, flexibility and straightforward approach has been our company’s strategy for success from the very beginning. For this reason we are in the position to supply our customer’s development divisions with machine parts, spares and prototypes within a short time. We guarantee delivery of premium and custom-made products in the shortest possible time. Our customers from various economy sectors are ensured fast and competent Service.

Founded

1992

Employees

20 - 50

Certifications

Gnesau

Austria - 9563

It does not matter what kind of error or problem your system has. Our competent service team will take care of your matter. Our range of services from Remagen is very diverse. We offer the right solution for you, from maintenance to assembly service and CNC production to a wide range of spare parts. We will also help you in the field of special plant construction. We offer each customer an individual solution that is tailored to the customer-specific branch or industry. Because no area of application is like the other. Our technical know-how and innovative solutions ensure a great competitive advantage that is worthwhile. Take us to Ko

Founded

2020

Employees

< 5

Certifications

Sinzig

Germany - 53489

We comprehensively create welded and mechanically processed structures. Technologies: -Welding and assembly; -Mechanical processing, milling, turning; The company SPAW-KON has been successfully carrying out orders in the field of metal parts production and machining since 2009. We are happy to accompany our Clients in project implementation, by adjusting to their needs and creating a platform for development. We believe that people make growth possible. In Gorzów Wielkopolski, we have modern production halls with an area of 1500 m2 and an experienced team of specialists. We look forward to working with you! Sincerely, the SPAWKON team

Founded

2009

Employees

20 - 50

Certifications

Gorzów Wielkopolskim

Poland - 66-400

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Manufacture of plastic parts to 460 g, and 80 g of multi-component injection molding possible. Also specializes in parts with inlets of ceramic, metal, fabrics, films. Assembly, as well as ultrasonic welding of possible modules. Pad printing, screen printing, painting at suppliers.

Founded

1977

Employees

20 - 50

Certifications

Haigerloch-Owingen

Germany - 72401

D & D Production and Sourcing is a Dutch company with offices in the Netherlands (Bergeijk) and China (Shanghai). The firm was started in 2006 by the two directors/founders, Jan van der Donk and Hans van Dam. Since 2010 they have their own production (assembly) company WOFE in China (Shanghai). D & D Safe Sourcing is ISO 9001 certified and classified as Bosch preferred supplier. D & D Safe Sourcing uses two concepts: "Production for China" and "Production for Europe". 1) Production for China This concept is an interesting alternative for exporting products to China. We take the production of metal (including magnets) -, plastic products and electronics off at selected contractors. This includes also conduct the necessary tools for pressure die-casting, forging, stamping and so on. Parallel to the production in China, we will send your "strategic parts" to our office in China (Shanghai). After receiving all the products is the entrance control, assembly, final inspection, packaging and shipping space and from our factory. The final products are then sent on demand to your local plant in China. Cooperation with D & D Safe Sourcing means to you: • No copy risks • Shorter delivery times • Lower transport costs • Lower import duties • No copy risk • Local after sales support • You pay only upon delivery • European quality for a much lower cost We provide Dutch companies also store and after sales support by our Chinese staff. We successfully doing this for years for clients such as Nedap, Vanderlande and Gispen. 2) Production for Europe The production and assembly are the same as above, but we will send the final/intermediate products to Europe. Here, the final assembly and final inspection instead of your product with the required "key components". Cooperation with D & D Safe Sourcing means to you: �� No copy risks • No transport risks • You pay only upon delivery • European quality for a much lower cost Knowing more? Please contact me for an appointment at your office.

Founded

2006

Employees

20 - 50

Certifications

Bergeijk

Netherlands - 5571 LS

Welcome at Koeckert Formenbau Our company is based in Weiden. We are thus located in the centre of the Bavarian-Bohemian glass industry which is rich in tradition. Having been a company family-owned for three generations we have been judging for more than 50 years each order as sign of the confidence our business partners have had in us. All services and supplies made by the Koeckert Formenbau GmbH shall meet even the most demanding requirements of our partners and shall be convincing by economic efficiency and latest state-of-art-technology. Our product range comprises development-oriented activities, engineering work and the realization of even the largest projects. It is obvious that we are familiar with the most modern computer technologies as well as with precise handicraft. Each of our employees has been trained in our company and is actively and responsibly taking over his part at his daily work in order to reach the set targets. That is not always easy. However, we will succeed. Today and in the future. Thanks to the know-how and the zeal of all employees as well as to the high quality of their performance. Production Priorities Press moulds Blow moulds Injection moulds Centrifugal casting Diecasting Injection casting Model making and single-piece production Engineering Design Perfected mould in view of production and technique Moulds for the Glass Industry Press moulds, blow moulds, injection moulds, centrifugal castings etc. Consumer goods industry Tableware, fancy goods, objects, figurines Technical applications Glass articles for the lighting engineering industry, medical engineering Injection and Diecasting Moulds Household articles, electrical engineering, consumer goods and automotive sub-contractors' industries Model making and Single-piece Production Production of pilot lots and prototypes, job lots Materials Synthetic, plexiglass, wood, aluminium, steel, cast materials Engineering and Design Conversion of two-dimensional engineering drawings in three-dimensional models, elaborated manually or computer-assisted Engineering of the moulds and the tools Maximum size of workpiece: 1,000 x 700 x 800 mm Maximum weight of workpiece: 1,000 kgs

Founded

1949

Employees

20 - 50

Certifications

Weiden

Germany - 92637

WOOD DROPS CNC / Laser Technology Looking for the right partner when it comes to milling or laser machining in detail. With us, a young dynamic team deals with all your needs, to meet all the requirements at the highest level. WOOD DROPS accompanies you throughout the entire implementation, from the idea to the concept, from prototype through production, mass production, the elaboration of the design to the finished product. With our modern machinery and the expertise of our engineering teams, we have been perfecting all your plans. Contact us with your project and make you feel good advice in a family atmosphere.

Founded

2017

Employees

5 - 10

Certifications

Obertraubling, Oberhinkofen

Germany - 93083

With our machinery which milling centers, lathes, grinders and several EDMs and wire covers, we are ideally equipped for the production of technical components. Custom manufacturing of complex, drawing-based parts, including process and quality monitoring from the prototype up to series production, one of our strengths. In addition, we are also in the field of plastic injection molding, for the production of prototype and production tools, as well as for the spraying of parts, very well positioned. As big advantage for our customers, we see the synergies within the WOLF group. All parts can be also provided with the desired surface technology such as PVD hard material coating.

Founded

1985

Employees

100 - 200

Certifications

Bruchmühlbach-Miesau

Germany - 66892

From the first concept to the customized assembly group, we are your reliable partner. Modern injection moulding machinery by Arburg, Krauss-Maffei, and Battenfeld let us produce sophisticated technical parts for customers all around the globe. Our special expertise includes 2-component injection moulding, insert moulding, and physical foaming. Various additional steps such as galvanizing, printing, and creating complete assembly groups complete our range of services.

Founded

1983

Employees

50 - 100

Certifications

Kierspe

Germany - 58566

Founded

Employees

10 - 20

Certifications

Kocaeli

Turkey - 41140

CNC -EXPERT is a cnc turning and milling company. We manufacture parts from almost all machinable materials. In particular, black steel, acid-resistant steel, aluminum, brass, plastics (POM-C, PA6, Pa66)

Founded

2014

Employees

10 - 20

Certifications

Białystok

Poland - 15-680

The VolaPlast Group is one of the most modern and innovative plastics processing companies in Europe. For over 60 years, we have been manufacturing technical plastic parts at the highest level for the automotive industry, medical technology and other industries. Thanks to our locations in Spangenberg in northern Hesse and in Kyustendil, Bulgaria, we can offer you not only plastic parts but also complex assembly of components with an optimal cost structure. This allows us to offer you everything from manufacturing to assembly, welding, gluing, printing, packaging, transportation to organizing warehousing.

Founded

1961

Employees

200 - 500

Certifications

Spangenberg

Germany - 34286

We started in 1988 with the production of thermosets all materials and brake linings. From this experience, we combine metal / plastic pairings in-house development and own production. Hot glue the metal / plastic products. We are with our own brands worked on maintenance-free plain bearings market and have the brands AS-F 100 and VaneStar unique materials in use worldwide. The close connection to the engineering, automotive engineering, compressed air equipment industry, special machine and many we have and a year ago decided metalworking expand. Therefore, the Schuler Technoparts was founded in 2009 and equipped with a large modern machinery. With our 5-axis milling machine with rotary table 700 in connection to SolidCam we can cover a wide spectrum. These are planning a 3-axle long bed milling machine and a small 5 axis milling machine. With our 12 stations 3 axis EMCO and the HSC Datron and an ELB Surface Grinder with 600x1.000 working surface we can continue to cover operations. At the EMO we bought new 4-axis CNC lathe EMO Turnmill 65 Bigbore for 95 mm rods D to 420 mm, Zoller adjustment equipment for milling and turning, Mitutoyo measuring machine with measuring range 700x500x400 mm Finishing machine for deburring and polishing Band saw for round material D 360 mm and flat 500x250mm - Polishing, deburring, finishing, barrel finishing, assembly, surface treatment - Complete production - Measuring and testing Delivery program: Jacks, complete machining, plastic parts, VA, PEEK, PAI, devices and plain bearings, slides, pumps and compressors, friction materials, insulation products Industries: construction machinery, cranes, cranes, presses, manufacturing, tooling, power transmission, measuring equipment, tripods, cleanroom technology, special engineering, mechanical engineering, vehicle

Founded

1988

Employees

10 - 20

Certifications

Freiberg am Neckar

Germany - 71691

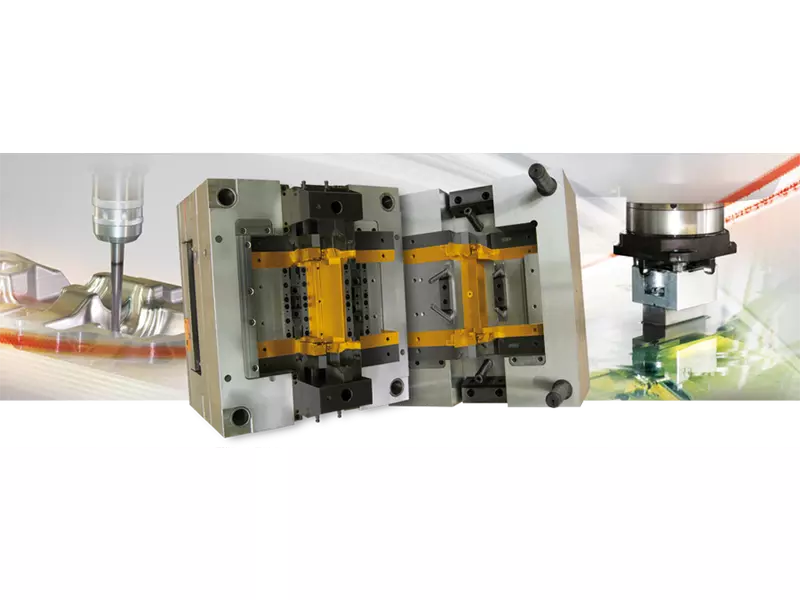

FWB Kunststofftechnik GmbH stands for innovative development work and technical expertise in injection moulding technology. We provide comprehensive support to our customers to ensure the highest manufacturing quality – from the idea via design up to the precise manufacturing of the injection moulds. This is not only the basis for functional and reasonable precision products made of plastics but also for an efficient and successful cooperation with our customers. For 30 years now, FWB Kunststofftechnik GmbH has met the individual requirements of renowned companies in Germany and abroad. With the fields of activity like injection-moulding tools, automation, plastic parts (with a shot weight range of 2 – 650g) and assembly, we generate a turnover of approx 15 million euros. As a forward-looking company we want to be at the forefront of the international plastics industry – including the related tool manufacturing. We focus on innovation in plastics, we focus on mastering complicated processes and developing high-capacity tools. In Germany, we are already one of the leading companies for individual solutions in our core technologies.

Founded

1980

Employees

100 - 200

Certifications

Pirmasens

Germany - 66955

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

SR Tech specializes in the production and import of customized technical items. Founded in 2011, the company soon established itself on the market as a reference partner for all companies that need help in choosing the best production technology for cost-effective mechanical components The company focuses on supplying mechanical components with a highly technological, aesthetic and functional content, ensuring the continuity of supply through the management of the stocks at KanBan’s headquarters in Parma. Customer satisfaction is guaranteed by the respect of delivery times, by the quality of supplies and by the competitiveness of purchase costs that we are able to obtain thanks to the experience gained in outsourcing through over 15 years of activity with Asian suppliers.

Founded

2011

Employees

5 - 10

Certifications

Parma

Italy - 43122

Each year, we produce around 20 million injection moulded parts, primarily for the automotive industry. The parts we produce are used in the following vehicles, among others: Audi, Bentley, BMW, Chrysler, Maybach, Mercedes, Opel, Porsche, Rolls Royce, Seat, Skoda, Toyota, and VW. The following international automotive suppliers form part of our customer base: Continental Automotive GmbH and ITW Automotive Products GmbH. We deliver to locations in Australia, Brazil, China, France, India, Indonesia, Malaysia, Mexico, Switzerland, Spain, and the Czech Republic. We currently keep more than 2,000 injection moulding in working order in order to meet our customers’ needs. Specialist personnel service and maintain machines and carry out small repairs on our premises. Following a joint development process, new moulds are produced by experienced tool manufacturers in the close vicinity.

Founded

1997

Employees

5 - 10

Certifications

Michelstadt

Germany - 64720

Our main profile: Powder coating Precision Sheet Metal Punching, cnc Component manufacturing Corrosion protection We offer a complex service: - Planning the production of the components ponents surface treatment. Our company started as a small family business in 1997. The company started its production in a 300 m2 building with only an oven for powder coating. Today we have a 11,000 m2 - Production line with a 2000 m2 hangar. In the beginning we had only 4 employees, today we have a staff of 18 employees. From the beginning it has been our goal to produce quality products and to show our customers our best side. Due to our high quality standards, we were able to build long-term relationships with both national and international partners. Our company still operates as a family business, which helps us to keep administrative costs and our prices low. To adapt to the market, we introduced a service, which affect not only surface treatment, but also the complete production of equipment and spare parts in close cooperation with metallurgical enterprises. Our goal is to offer perfect services to our customers. Iso 9001 wiki

Founded

1999

Employees

10 - 20

Certifications

Bonyhád

Hungary - 7150

Bergplast Kunststoff GmbH & Co.KG is an owner-managed medium-sized company Family business with headquarters in Upper Franconia directly on the motorway A73. With our currently 50 employees we produce technical thermoplastic parts made of reinforced and unreinforced plastics in 1K and 2K processes. Our injection molding machines include tonnage sizes with clamping forces of 25 t. up to 350 t. In addition to the production of technical injection molded parts, the production of the associated injection molding tools is part of our service portfolio. Change requests of the customers are not a problem for us, because we have our own construction in addition to our toolmaking.

Founded

1984

Employees

20 - 50

Certifications

Neustadt bei Coburg

Germany - 96465

Harx Tooling Sp. z o.o.

Harx Tooling is an engineering company specializing in the development and supply of tooling and processing equipment as well as component manufacturing primarily for automotive TIER 1 and OEM customers. Our geographical location has us focused on the European market however, with over 25 years of experience, our equipment and services have followed our clients worldwide. We manage our projects in-house from pre-engineering analysis, mechanical and electrical engineering, PLC controls, robotics, to final installation and after-sale service. Our internal tool-shop is very well equipped from a machining standpoint and we invest in all opportunities which allow us to optimize and streamline our manufacturing capacities (3D printing, waterjet) while upholding strict quality standards backed by CMM measurement reports. We have manufacturing subcontractors in China and a service partners in Europe which act as first responders (24/7) for maintenance and customer support for local clients.

Founded

Employees

50 - 100

Certifications

Przeźmierowo

Poland - 62081

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge