Spray painting: find new suppliers on Techpilot

Discover specialized suppliers for spray painting on Techpilot. Our platform connects buyers with suppliers who use advanced painting technologies to achieve precise and high-quality surface coatings. Use the e-sourcing process to find the best suppliers.

499 suppliers for Spray painting

The H. Steinhart metal goods factory GmbH & Co. KG represents the most modern type of production techniques in cutting metal machining. Founded in 1954 by Henry Steinhart as a factory for craft metal products it developed from 1979 becoming one of the most modern services and specialists in the fields of Sheet & Tube processing / wire bending technology / manufacturing of complete assemblies including surface Annual investment of considerable sums of money in the latest manufacturing technology, a work done in over 20 years of know-how, and a team of highly motivated specialists with the desire for perfection are the basics for a steady increase in the efficiency of H. Steinhart metal goods factory GmbH & Co. KG. The three pillars of our corporate philosophy High quality standard Punctuality Flexibility make our company a reliable and competent partner for a broad customer base.

Founded

1954

Employees

50 - 100

Certifications

Hettingen

Germany - 72513

Surface finishing of aluminum (anodized), dyeing. Aluminum pretreatment trovalizing, glass bead blasting E0-E6 pickling and e-polishing of stainless steel Bath dimensions 3000x500x800 mm.

Founded

1969

Employees

20 - 50

Certifications

Lottstetten

Germany - 79807

inovaPlus is an engineering partner to the automotive , aviation ,defence and R&D industry providing complete solutions for product development projects. Our assets: A team of skilled and experienced engineers and technical experts specializing in project management , profession of CAD/CAE tools also know-how of engineering plastics, composite materials, prototype making techniques and moulding feasibility.

Founded

Employees

5 - 10

Certifications

Dreieich

Germany - 63303

Our company's activity is the production of metal products: fences, balustrades, carports, sheds, pillars, metalic boxpallet, etc. We have high-performance equipment for the processing and finishing of iron, such as: cnc plasma, powder coating painting line, welded and screw-rolling machines, cutters and many others for the realization of each project from a to z, at the highest standards. From design to reception, our team of professionals is present in your project. You can visit us at any time at our work point located on Abatorului street no. 12, Campia Turzii, Cluj county, to see how we are progressing with your works. IN ADDITION TO METAL CONSTRUCTION, WE ALSO OFFER VARIOUS SERVICES PRECUM: -Professional electrostatic painting services performed by qualified personnel and state-of-the-art equipment. Polymerization oven capacity: L7000mm x l1460mm x h2680mm (L7m x l1.46m x h2.68m). Various colors and textures (the entire RAL range) and not only. Any type of metal parts, eg: railings, fences, decorative panels, chassis, rims, bicycle frames, urban furniture, metal constructions, etc. -Cutting, sheet metal cutting with cnc plasma, sheet thickness 2-25mm. In this way, decorative metal panels, cabals, pillar soles, etc. can be made - Bending profiles and sheets metal - Welding Tig Wig Mig Mag - etc

Founded

2023

Employees

5 - 10

Certifications

Campia turzii (Cluj)

Romania - 405100

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Sheet metal processing company with a focus on the production of boxes and housings Founded in 1869, 175 employees, complete added value from construction to complete sheet metal processing including powder coating and assembly and shipping and, if required, assembly on site

Founded

1869

Employees

100 - 200

Certifications

Döbeln

Germany - 04720

Industrial Business Products As a supplier of products for the machinery, equipment, apparatus and vehicles, we are to do justice in a position to even the most complex requirements in the production of sheet metal parts and assemblies. Modern CNC machines for sheet processing of metal sheets by punch nibbling / shaping, lasers and flexible folding of this material are complemented by tailored joining, welding and assembly technologies. The secret of our performance in terms of precision, speed of implementation and flexibility on the one hand, the direct coupling of this technology in our 3D CAD system Pro / Engineer and on the other the lived symbiosis of qualified craftsmanship and modern technology. So we are not only able already to produce predefined products efficiently from small batches, but can offer our customers complex solutions to problems. Surface Treatment business With our self-developed powder coating line we are pursuing the goal of making new powder coating technologies are made accessible for the majority of the area. As a modern service company, we offer our customers factory coatings for components and structures up to a size of 12,000 x 3,200 x 2,400 mm (L x H x W). Specially adapted and tested single and multi-layer technologies for components and structures made of steel, galvanized steel and aluminum provide solutions for both indoor as well as outdoor range up to the marine environment and for heavy corrosion protection.

Founded

1996

Employees

20 - 50

Certifications

Breitungen

Germany - 98597

Dear ladies and gentlemen, In the attachment, you will find our contact details and company presentation. We are taking this initiative because we are convinced that our quality and expertise will also benefit you and your company. In addition to the actual troweling and mass finishing service in various batch sizes, we also sell our own compounds at reasonable prices. We would be happy to provide you with a non-binding offer upon request. Y. Korbulak OTSM GmbH email:

Founded

Employees

20 - 50

Certifications

Pforzheim

Germany - 75177

We are a medium-sized, metal processing company with its own development and production in Germany. The combination of modern working processes and decades of experience, we will continue to try to make your success our innovative edge. What does this mean for them? Professional project planning, Quick decision-making, Short delivery times and unique quality. Why do you need it? Because your technique also is not any, and thus there is no reason to settle for less to be satisfied... Our core competencies CAD design in 3d In general, metal processing Specifically, sheet metal processing Bending / folding sheets up to a thickness of 8mm (CNC gesteuet) Punching / nibbling sheets up to a thickness of 8mm (CNC controlled) Welding of steel, stainless steel, aluminum, cast Glass bead blasting Polishing Priming and painting Maintenance Preparing the materials for o chromating o Galvanizing o Anodizing o Powder coating Special experience Development and construction of frames and components in 19 "Technology Development of radio and television broadcast van Studio Furniture Vehicle interior fittings (special designs) Monitor walls Casing of development through prototyping to

Founded

1994

Employees

20 - 50

Certifications

Langenlonsheim

Germany - 55450

STS SUMPERK a.s.

Established in 1949, the STS Sumperk company manufactured by the last 20 years thousands of agriculture machines. Today STS Sumperk company makes its turnover 90% out of sub-contracting for significant customers like General Electric, Mercedes Bus, Siemens and Tatra. We are exporting more than 80% production to the EU countries. The skilled workers in well-equipped production plants manufacture all products in top quality and just in time. Our commercial and technical staff led a team of 180 professionals. Our key activities are: - NC machining (maximum size 800 mm x 800 mm x 720 mm) - NC Plasma cutting (25 mm x 3200 mm x 1600 mm) - NC press brake (160 t, maximum size 3150 mm) - Horizontal Boring machining (maximum size 1250 mm x 1250 mm x 900 mm) - Welding of steel, stainless steel and aluminum - Mechanical assembly up to 3.500 kg - Top quality painting box (maximum size 8000 mm x 3400 mm x 3000 mm) - Grey iron casting (maximum size 1000mm x 1000 mm x 1000 mm) Thanks to its experience and know-how, STS Sumperk guarantees the manufacturing of your fabricated components, steel structures and Grey iron castings in total respect of quality requirements and of delivery dates. Our company offers you the services of a high performance and multipurpose industrial tool.

Founded

1949

Employees

100 - 200

Certifications

Vikýřovice

Czech Republic - 788 13

More than 40 Years Experienced in Tobacco Industry Jacobi has been established by Lothar Jacobi in 1967. He became favorite partner to the leading German tobacco companies - focussing on maintenance, rebuilding and manufacturing of outstanding solutions. After having merged with the Eastern German tobacco specialist Systemtechnik his son, Frank Jacobi, has taken over the management of the well established manufacturer of customized equipment. Storage, dosage and transportation of tobacco bins, cardboard boxes and cutfiller represent Jacobi's core skills. Their individually designed solutions link Primary and Secondary machinery at high quality standard. As the expert in the industry Jacobi is successfully meeting the exclusive requirements of global acting companies in the tobacco industry.

Founded

2009

Employees

20 - 50

Certifications

Arnsdorf

Germany - 01477

Step by Step: From blank to paintable product The basis for a clean paintwork: a fat and grease free substrate. However, especially in the metal processing of permanent use of lubricants is essential that supplied us parts are therefore not readily paintable.

Founded

2004

Employees

Certifications

Villingen-Schwenningen

Germany - 78048

We subcontractors industrial cutting. LASER PLASMA OXYCOUPAGE. Boiler, welding, painting. WIR SPRECHEN DEUTSCH. HABLAMAOS ESPAÑOL. WE SPEAK ENGLISH.

Founded

1997

Employees

10 - 20

Certifications

BIDART

France - 64210

Founded

2005

Employees

5 - 10

Certifications

Rödental

Germany - 96472

Let us introduce ourselves The company’s headquarter is located in Speyer am Rhein. The origins of VETEC Ventiltechnik GmbH can be traced back to the original founding of the company in 1901. Adding a separate valve section in 1964 was the starting point for product development, whose solutions have been successfully monitored to date by our customers’ manufacturing processes. After renaming the company VETEC Ventiltechnik GmbH in 1985, this know-how continues to guide and develop the company. We have been a subsidiary of the SAMSON group - one of the leading companies for measuring and control technology - since 1988. SAMSON AG in Frankfurt am Main is the group’s parent company. By collaborating with this strong partner, we have a presence in engineering and sales offices all over the world.

Founded

1964

Employees

100 - 200

Certifications

Speyer

Germany - 67346

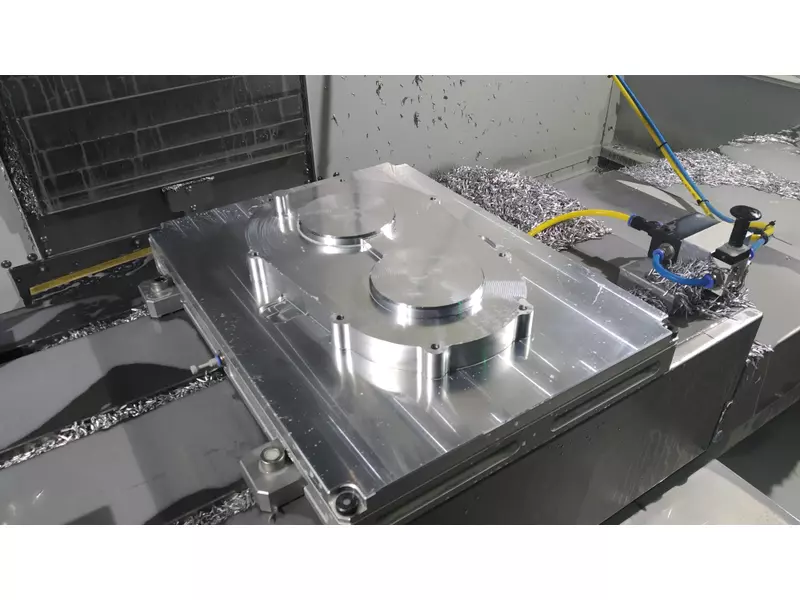

Mechanical large parts machining of machine parts with a focus on guideway grinding

Founded

1922

Employees

5 - 10

Certifications

Bünde

Germany - 32257

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

AH-Oberflächenveredelung is a small one-man business with a focus on small series painting. Long experience, know-how in the series area. CFK, GFK, aluminum, metal. and much more.

Founded

2019

Employees

< 5

Certifications

Grassau

Germany - 83224

Dear , Let me speak with this brief presentation of the company Leistritz Turbinenkomponenten Belišće doo, a Croatian subsidiary of the German company Leistritz AG With regard to the similarity of our activities in the metal industry, the processing of metal parts for the aerospace, automotive and mechanical engineering industries, we offer you the possibility of business cooperation. In our factory in Belišće we carry out the following operations and manual processing: - Deburring, grinding with belt grinders - grinding and polishing - High-energy vibratory grinding (barrel with 2 Walther Trowal machines) - Visual inspection - Dimensional check - 3D CNC measurement (Global, Brown & Sharp - 4 devices) - 3-axis NC milling (1 piece MAHO 600) We have significant experience in the processing of blades and metal parts for all major manufacturers of jet engines and steam turbines such as Rolls & Royce, MTU, ITP, General Electric, SIEMENS, Pratt & Whitney. As a reliable, high quality and certified supplier, I would like to offer you our services and make them available to you. For a more detailed introduction and presentation, we will be personally available to visit you at the company's headquarters. Waiting for your reply! Best regards, Atila Kerekeš, ing. / Zoran Pepić Quality manager / production manager - procurator Leistritz turbine component Belišće doo Trg A. Starčevića 1 31551 Belišće, Croatia Tel .: +385 31 662 656 Fax: +385 31 662 683

Founded

2005

Employees

20 - 50

Certifications

Belisce

Croatia - 31551

Created in 2015, Gannet Machine Works is a Vacuum WorkHolding & Subcontract Manufacturer for high precision CNC machined technical parts, working for the Marine, Rail and Industrial sectors. We also provide surface treatment and pre-assembly as well as Engineering services such as: Part design & Development, simulation, testing and prototyping. Website & Online Store: https://www.gannetmachineworks.eu/

Founded

2015

Employees

5 - 10

Certifications

Esposende

Portugal - 4740-543

Steel is our lifeblood - that's us LSV Lech-Stahl Veredelung GmbH was formed from two traditional bright steel companies in 2012. Lech-Stahl Veredelung in Oberndorf am Lech and Stahlveredelung Landsberg (SVL) have merged to form LSV Lech-Stahl Veredelung GmbH based in Landsberg am Lech. To implement new technologies, another location was built in the immediate vicinity of the parent company Lech-Stahlwerke in Meitingen in 2019. LSV Lech-Stahl Veredelung GmbH is a 100 percent subsidiary of the only steelworks in Bavaria, Lech-Stahlwerke GmbH in Meitingen. Both companies are part of the Max Aicher Foundation group. Our parent company is one of our largest suppliers of raw materials and supplies us with steel made from 100 percent recycled scrap. Due to this corporate structure, it is possible for us to fall back on the entire value chain and the associated expertise. The approximately 300 employees at the three LSV locations are committed people who are passionate about it. Decades of experience in the production of bright steel and the refinement of steel as well as the pursuit of the highest quality make it possible to realize the wishes of our customers and to establish close customer loyalty. Passion also means reliability paired with qualification. Therefore, in addition to the technically sophisticated production facilities, our employees are the basis for our success. LSV location Landsberg am Lech headquarters At the location in picturesque Landsberg am Lech, over 50,000 tons of bright steel are produced annually in a wide variety of refinement and processing stages. The focus is on the production of high-precision and ground toothed rack blanks as well as inductive single bar tempering. In addition, there are all classic bright steel processes at the highest level. LSV location Oberndorf am Lech The tranquil Oberndorf am Lech in the Donau-Ries region is the location of a completely modernized and expanded company with a capacity of over 80.000 tons per year. A high-tech bright steel production also forms the basis for the further refinement of the products. Short piece production and tempering systems at the highest technical level enable deeper added value in the production chain. The youngest LSV location in Meitingen Our third production site in Meitingen has been in operation since 2019. In addition to an outdoor warehouse and central warehouse of the parent company Lech-Stahlwerke, we produce steel in different processing and processing stages on almost 10,000 square meters in two aisles. In addition to the most modern production lines, the youngest LSV location has a motivated and flexible team that draws on the many years of experience of the other two locations.

Founded

Employees

200 - 500

Certifications

Landsberg am Lech

Germany - 86899

Veltech is an engineering & manufacturing company located in Turkey. With its wide variety of technologies (Machining, turning, welding, coating, sheet metal processing and Heat treatment) on its machine park, Veltech is an AS9100 certified supplier of Aerospace & Automotive companies.

Founded

Employees

20 - 50

Certifications

Düzce

Turkey - 81100

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge